DOC 0004-SP

1

Revision 06/18/14

OPERATOR’S MANUAL

FOR LOW PROFILE

12,000 RPM 5 in. (127 mm) and 6 in. (150 mm)

RANDOM ORBITAL SANDERS

Manufacturer/Supplier

DIXON ENTERPRISES, INC.

571 BIRCH STREET LAKE ELSINORE,

CA 92530

Tel: 951-245-4200

Fax: 951-245-4299

All SurfPrep

TM

Random Orbital Sanders are warranted for defects in materials or workmanship for one year from the

date of delivery to the user. Combined with the SurfPrep

TM

superior quality, durability, and performance of the SurfPrep

TM

LP. To receive any expressed or implied warranty, tool

must be repaired by an authorized SurfPrep

TM

Service Center. The “Service Instructions” section in this document

is provided for use after completion of the warranty period. To receive warranty, tools must be operated under the

conditions as described in the “Putting the Tools into Service” section of this document and be connected to an air

supply system as shown in Figure 1. Tools that have been exposed to extreme conditions will be covered under war-

ranty at the sole discretion of SurfPrep

TM

Warranty

Please Read and Comply with:

Proper Use of Tool

1) General Industry Safety & Health Regulations, Part 1910, OSHA 2206, available from: Superintendent of Docu-

2) Safety Code for Portable Air Tools, ANSI B186.1 available from: American National Standards Institute, Inc.; 1430

Broadway; New York, New York 10018

3) State and Local Regulations.

This sander is designed for sanding all types of materials i.e. metals, wood, stone, plastics, etc. using abrasive

manufacturer or the manufacturer’s authorized supplier.

Do not use back-up pads that have a working speed less than 12,000 RPM free speed. Never use back-up pads

Required Personal Safety Equipment

Safety Glasses

Breathing Masks

Safety Gloves

Ear Protection

Recommended Airline

Size - Minimum

10 mm

3/8 in

Recommended Maximum

Hose Length

8 meters

25 feet

Air Pressure

Maximum Working Pressure 6.2 bar 90 psig

Recommended Minimum

NA

NA

Declaration of conformity

DIXON ENTERPRISES, INC.

571 BIRCH STREET LAKE ELSINORE, CA 92530

declare on our sole responsibility that the products

Table for particular Model) to which this declaration

relates is in conformity with the following standard(s) or other normative document(s) EN ISO 15744:2008. Following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC 93/68/EEC Directives and consolidating Directive 2006/42/EC

Place and date of issue

Name

Signature or equivalent marking of authorized person

Important

Read these instructions care-

fully before installing, operating,

servicing or repairing this tool.

Keep these instructions in a safe

accessible location.

03.20.2013

Meri Faria

Operator Instructions

Includes – Please Read and Comply, Proper Use of Tool,

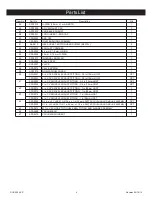

Parts Page, Parts List, Work Stations, Putting the Tool Into

Service, Operating Instructions and Compressor Layout,

Back-Up Pads, Service Tools and Accessories, Overhaul

Service Kit, Spare Part Kits, Service Instructions.

Original Instructions