18

1. The unit has a 5-minute delay on start-up

before beginning normal operation. Before

troubleshooting, ensure that 5 minutes have

passed.

2. Check the temperature set-points of the

controller to verify that the desired settings are

still in place. The factory differential temperature

should be 3 degrees, and shouldn’t be changed.

For example, with the factory set differential

temperature setting of 3 degrees, and a desired

temperature setting of 45°F (8°C), the unit will not

start until the water reaches 48°F (9°C).

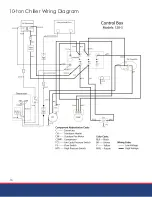

4. Check to make sure the controller is set to C1.

5.

QUALIFIED SERVICE PERSONNEL ONLY:

Check

voltage at relay (space terminals on each side),

which should be 24VAC while the temperature

controller is calling for cooling, then check for a

loose wire on the controller. If none are found,

check for power at the relay inside the controller.

If you have power there the other cause would

be a tripped high/low pressure sensor, in which

case an HVAC technician will need to service

your unit. He/she should check the refrigeration

pressures with a gauge set to verify that there is

not a problem with system pressures. If no

problems are found with pressure, then the high/

low pressure sensor may need to be replaced.

6.

QUALIFIED SERVICE PERSONNEL ONLY:

Check

the voltage across the ENDS of the main relay

with a meter. This should be 240VAC on each

side when the temperature controller is

Troubleshooting

This unit is equipped with safety sensors that may

include high and low pressure sensors for the

refrigeration circuit and also a flow switch to help

prevent freezing if there is a pump failure or other

loss of flow. If any of these sensors are not

satisfied, they will not allow the chiller to function.

Some of the troubleshooting steps listed below

can be performed by the end user, and some

of these steps must be performed by a licensed

HVAC technician. Retain this guide should your

chiller ever require servicing in the future.

Temperature controller has

no power

1. Check and make sure switch is in the on

position.

2. Check breaker for proper function.

3. Check flow meter for adequate water flow

(2.5 GPM per ton). Insufficient flow will cause

loss of power.

4.

QUALIFIED SERVICE PERSONNEL ONLY:

Check

flow for proper voltage at the unit with an

electric volt-meter.

5. Visually check for any loose wires.

6.

QUALIFIED SERVICE PERSONNEL ONLY:

Remove the front cover of the temperature

sensor and check voltage. If 24 VAC is

present, and all wires are installed and tight,

then most likely the controller will need to be

replaced. If no voltage is present, see the next

step.

7. The controller is wired so that it will not come

on if there is not sufficient water flow to the unit.

If there is no voltage at the controller, check

the flow and verify that the chiller is receiving at

least 2.5 GPM for each ton of cooling required.

If there is sufficient flow, see the next step.

8. Check connections of the flow sensor (the

flow sensor is installed in the water line) to make

Temperature controller

is on, but the unit will not

start

sure you are getting 24VAC across the sensor

while sufficient water is flowing. If there is no

voltage across the sensor leads with a

proper flow-rate, then the sensor needs to be

replaced.

9. Check the direction of flow in the water circuit.

If water is flowing backwards, the flow switch will

not allow power to the temperature controller,

and the unit will not function properly.