If you prefer to use the spring adjustment

method, you will need to remove each knife,

remove the jack screws, leave the two springs

under each knife and replace the knife. Follow

the steps below if using the spring adjustment

method.

WARNING: MAKE CERTAIN THAT THE SAW

IS DISCONNECTED FROM THE POWER SOURCE.

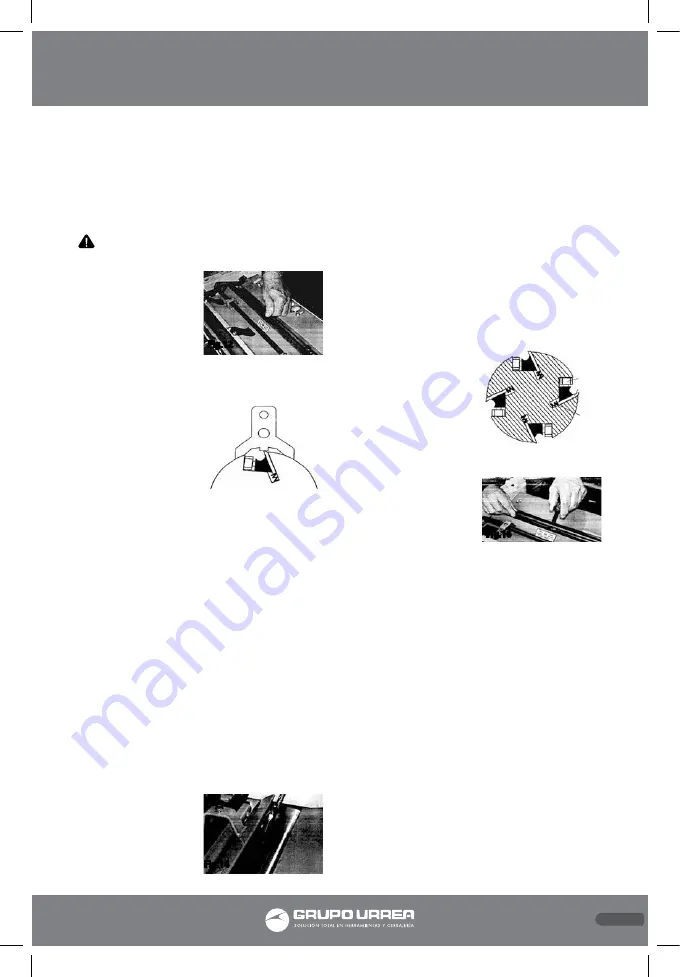

1. Move the hinged

dust port and upper

cover assembly to ex-

pose the cutterhead

(fig.12).

2. Remove the belt guard. Turn the cutterhead

(using the pulley) until the first knife is top

dead center.

3. Using the knife set-

ting gauge, check the

knife height. The jig

should sit with both

feet on the cutter-

head. See figure 13.

If the knife is properly adjusted, the contact

point at the center of the gauge should just

touch the tip of the knife. If the knife does not

make contact, or if the knife is high enough to

cause the legs of the gauge no to set on the

cutterhead, the knives will need adjusted. Be

sure to inspect all 4 knives in the same manner.

The planer knives will need to be adjusted

periodically and ultimately will need to be re-

moved to be sharpened. Adjustments should

be as precise as possible with tolerance with-

in .0002”-.003”. This will help to prolong the

sharpness of the knife edges. Improperly ad-

justed knives can cause an imbalance condition

in the cutterhead and shorten bearing life, as

well as produce substandard results.

4. Loosen the gib bolts by turning them clock-

wise until the knife is loose in the slot.

5. Carefully remove the knife.

6. Unscrew the jack screws completely from

threaded hole and remove.

7. Be sure that there is

one spring in each of

the of the two holes

in the bottom of the

knife slot. See figure

14.

NOTICE: The springs DO NOT go into the

threaded hole where the jack screws were in-

stalled.

KNIFE ADJUSTMENT

The knives are locked in the cutterhead with

the wedge type gibs and gib bolts Spring locat-

ed under the knives assist in setting the knife

height. Jack screws under the knives allow fine

tuning to help out in the setting process.

1. MAKE CERTAIN THE MACHINE IS DISCON-

NECTED FROM THE POWER SOURCE.

2. Move hinged upper cover assembly to ex-

pose the cutterhead.

3. Loosen the gib bolts

until the knife is loose

in the slot. The gib

bolts turn clockwise to

loosen and counter-

clockwise to tighten.

See figure 15.

4. Place the knife set-

ting jig over the knife

on the cutterhead as

shown in Fig 16. The

feet of the jig should

be securely planted

on the cutterhead,

making sure the gauge rod remains parallel to

the cutterhead. See figure 16.

5. Lower the jack screws as low as possible.

6. Maintain a steady pressure on the knife set-

ting jig while retightening the gib bolts. The

springs in the cutterhead will push up on the

knife allowing for proper alignment of the

knives.

7. Once gib bolts are tightened, raise jack

screws until they just touch the bottom of the

knife. You should feel resistance when the jack

screw touches the bottom of the knife.

NOTICE: When making adjustments to the

planer knives, all four knives must be adjusted

the same. DO NOT adjust one knife without

adjusting the others as this can result in knife

damage, poor performance and possible injury

to the operator.

CHIP BREAKER

The chip breaker is located on the top side of

the planer and it extends down around the

front of the cutterhead. The purpose of the

27

E N G L I S H •

User's manual

Fig.14

Fig.16

Fig.15

Gib bolt

Knife

Spring

Fig.12

Fig.13

CE716-CE720 manual.indd 27

29/06/15 16:30