to gauge the distance between the chip deflec-

tor and the knives.

CAUTION: If the chip deflector is set too close

to the knives, the rotating cutterhead may pull

it in and destroy it.

2. If adjustment is necessary, loosen the three

deflector mounting bolts.

3. Make sure the beveled edge of the deflector

faces the cutterhead.

4. Move the deflector until the edge is approxi-

mately 1/8-1/4 from the edge of the knives.

5. Push down on the deflector with a wooden

stick and spin the cutterhead by hand to en-

sure that it does not contact the knives.

CAUTION: Planer knives are extremely sharp.

Please use extra caution when your hands are

near the blades.

6. Retighten the chip deflector mounting bolts

and remount the upper cover and dust port to

the planer.

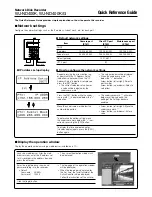

ANTI-KICKBACK FINGERS

Anti-kickback fingers

(Fig.24a) are an added

safety feature on this

planer. They are sus-

pended from a rod

that hangs across the

front of the cutterhead casting. These fingers

should be inspected regularly, ensuring that

they swing freely and easily.

WARNING: DO NOT apply any oil or other

lubricant to the antikickback fingers as this can

attract dust and restrict the free movement of

the fingers. This could result in damage to the

planer, the workpiece, or even serious injury to

the operator or others in the work area.

DO NOT attempt to use the planer if the anti-

kickback fingers are not functioning properly.

PULLEYS

WARNING: Make certain the machine is dis-

connected from the power source.

1. To inspect pulleys, place

a steel ruler or other type

of straight edge across the

pulleys to check the align-

ment. If the ruler crosses

them evenly, the pulleys

are aligned correctly.

a

Fig.24

Fig.25

2. If pulleys are out of alignment, loosen the

bolts the pulley can be adjusted as wall as mov-

ing the motor mount bracket.

3. Adjust the motor position until the pulleys

are aligned.

4. Retighten all bolts.

BELTS

WARNING: Make certain the machine is dis-

connected from the power source.

1. If the belt is too loose, remove the belt

guard using the two threaded knobs.

2. To check belt tension, squeeze the Belts at

their midpoint with moderate finger pressure.

You should be able to deflect each belt no

more than 3/4.

3. Remove the panel at the back of the ma-

chine stand to access the motor assembly.

4. The motor pivots on

a platform suspended

at one end by two

threaded adjustment

bolts. Adjust the lock-

nuts (Fig.26a) up or

down the shafts until the desired belt deflec-

tion is achieved.

GEAR BOX

The gearbox is located just behind the hand-

wheel on the right side of the planer. The

gearbox transfers power from the belt driven

cutterhead to the power feed rollers. It has a

two speed transmission that is controlled by a

lever on the right side of the planer. When it

is engaged, the power feed rollers will move

the workpiece through the planer at either 16

ft/ min or 30 ft/min. The center position on the

lever is neutral.

1. To inspect gearbox, loosen the socket head

cap screw on the gearbox cover.

2. Pull the cover off the roll pins that hold it in place.

NOTE: There are two metal guard plates bolted

to the backside of the gear box cover. It may

be necessary to remove one of these guards in

order to remove the gear box cover.

3. Inspect the bolts

that hold the sprock-

ets in place.

4. Check the drive

chains to make sure

that the retaining clips

are in place (Fig.27).

Fig.27

Fig.26

a

b

30

CE716-CE720 manual.indd 30

29/06/15 16:30