Installation and Commissioning

P Line Touch Panel

34

2.3

Connecting the Device

2.3.1

Supply Voltage

The supply voltage is supplied via pin strip X1. A suitable socket strip is supplied.

Refer to the technical data for the permissible supply voltage of the operating de-

vice.

Connector in the operating device: 3 pin pin strip

Use the following procedure to connect the device to the supply voltage:

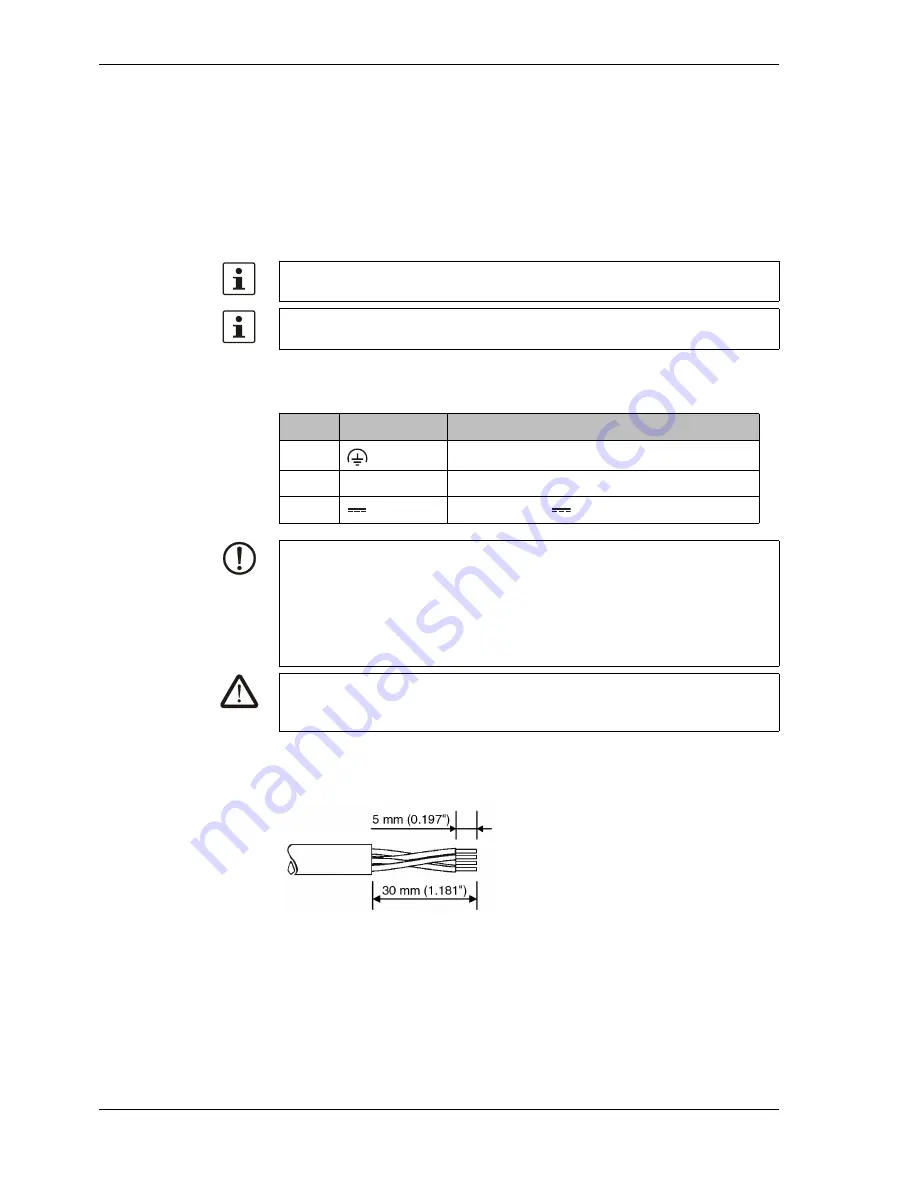

1. Strip approx. 30 mm (1.181") off the outer cable sheath and approx. 5 mm

(0.197") off the wires.

Figure 2-26 Preparing the cable

2. Fit the wires with wire end ferrules and connect the wires to the socket strip.

3. Plug the socket strip onto pin strip X1.

4. Secure the socket strip in place with a screw-type locking to prevent it from

slipping out.

The device has reverse polarity protection. In case of wrong polarity, the device

will not operate.

This is a protection class I device. For safe operation, safety extra-low voltage

(SELV) in accordance with DIN EN 61131 must be used for the supply voltage.

Table 2-1 Pin assignment supply voltage

Pin

Designation

Function

1

Noiseless ground / functional earth ground (FE)

2

0 V

Supply voltage 0 V (GND)

3

24 V

Supply voltage

24 V

NOTICE: Damage

Cables with finely stranded copper conductors with a minimum cross-section of

0.75 mm² (18 AWG) and a maximum cross-section of 2.5 mm² (14 AWG) must

be used for the supply voltage.

You must adhere to the following torques at the connector:

Screw connection of terminal blocks: 0.22 Nm (minimal) to 0.25 Nm (maximum)

Screw flange: 0.3 Nm (maximum)

DANGER: Hazardous voltages

Hazardous voltages can exist inside electrical installations that can pose a dan-

ger to humans. Coming in contact with live parts may result in electric shock!

Summary of Contents for P Line

Page 6: ...Overall Table of Contents P Line Touch Panel 6...

Page 42: ...Installation and Commissioning P Line Touch Panel 42...

Page 44: ...Control and Display Elements P Line Touch Panel 44...

Page 58: ...Interfaces of the Device P Line Touch Panel 58...

Page 62: ...Maintenance and Servicing P Line Touch Panel 62...

Page 98: ...Ordering Data P Line Touch Panel 98...

Page 100: ...100...

Page 101: ......