Engine Mechanical: 1D-23

• Install the piston and piston pin.

NOTE

When installing the piston, the indent “A” on

the piston head must be faced to exhaust

side.

• Place a clean rag over the cylinder base so as not to

drop the piston pin circlips (1) into the crankcase.

• Install the piston pin circlips (1).

CAUTION

!

Use new piston pin circlips (1) to prevent

circlip failure which will occur when it is bent.

NOTE

End gap of the circlip (1) should not be

aligned with the cutaway in the piston pin

bore.

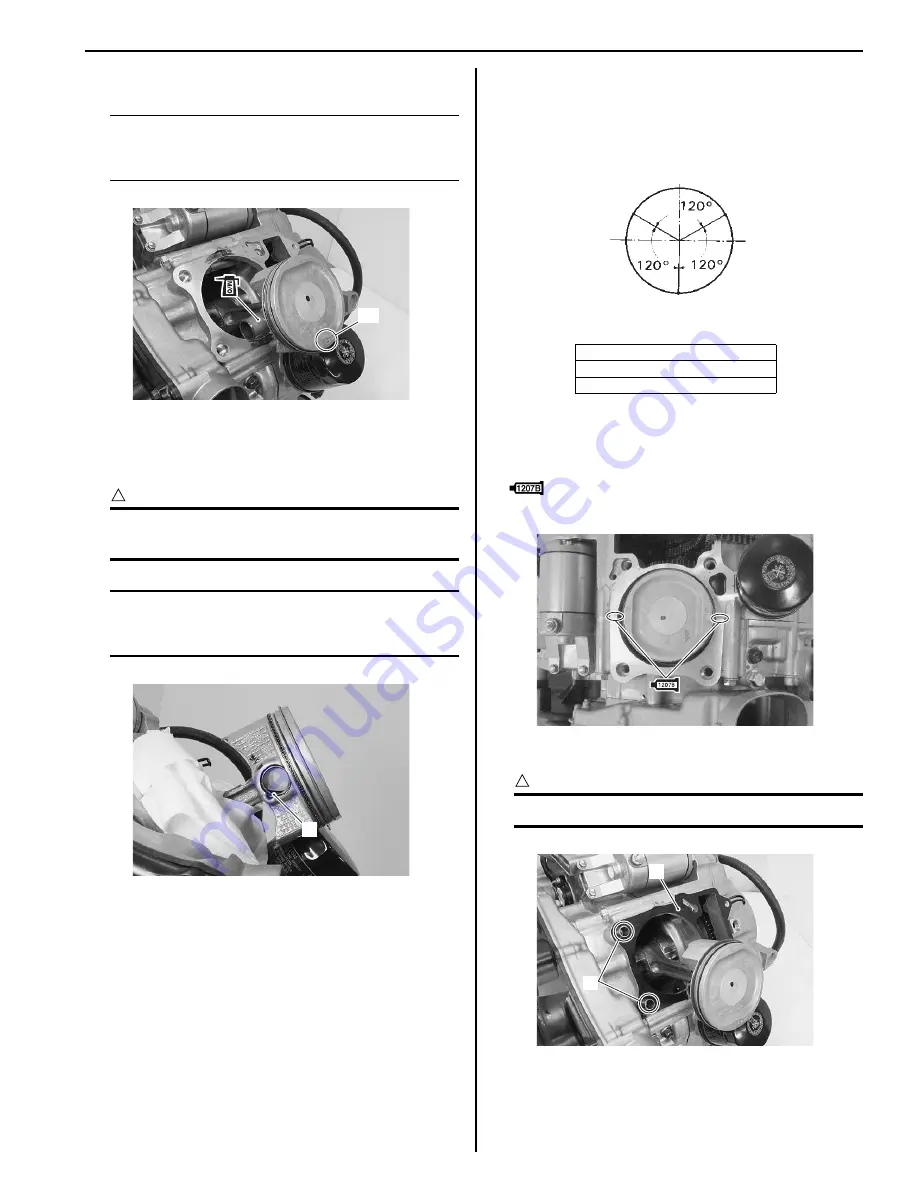

• Position the gaps of the three rings and side rails as

shown in the figure. Before inserting each piston into

the cylinder, check that the gaps are properly

positioned.

Cylinder

• Apply a bond lightly to the mating surfaces at the

parting line between the left and right crankcases.

: Sealant 99000–31140 (SUZUKI BOND

No.1207B or equivalent)

• Fit the dowel pins (1) and gasket (2).

CAUTION

!

Use the new gasket (2) to prevent oil leakage.

“A”

I931H1140085-01

1

I931H1140086-01

“B”: 2nd ring and lower side rail

“C”: Upper side rail

“D”: 1st ring and spacer

EX.

IN.

“C”

“B”

“D”

I931H1140292-01

I931H1140087-01

1

2

I931H1140088-01

Summary of Contents for 2009 LT-A500XP

Page 2: ......

Page 4: ......

Page 14: ...00 9 Precautions ...

Page 224: ...1E 3 Engine Lubrication System EXHAUST SIDE INTAKE SIDE I931H1150003 02 ...

Page 304: ...1K 4 Exhaust System ...

Page 346: ...2D 5 Wheels and Tires ...

Page 438: ...3D 26 Propeller Shafts ...

Page 482: ...4D 6 Parking Brake ...

Page 512: ...5A 28 Automatic Transmission ...

Page 624: ...Prepared by December 2008 Part No 99500 44080 03E Printed in U S A 624 ...