POWER UNIT 6-17

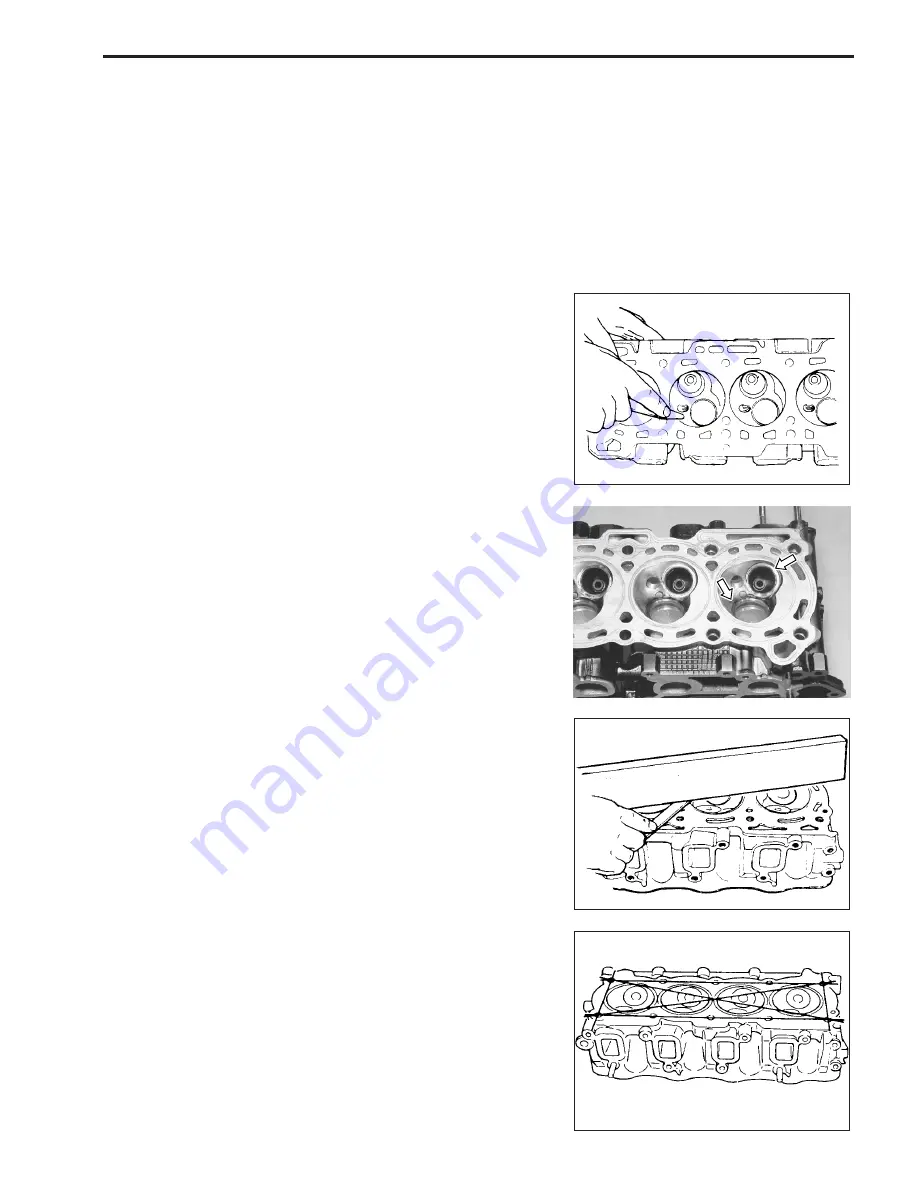

2. Inspect the intake ports, the exhaust ports, the combustion

chambers and the head surface.

If crack or other damage is found, replace the cylinder head.

INSPECTION / SERVICING

NOTE:

If crack, excessive wear or other damage is found on any com-

ponent, replace.

CYLINDER HEAD

1. Remove all carbon from the combustion chamber.

NOTE:

• Do not use any sharp edged tool to scrape carbon off the

cylinder head or the head components.

• Be careful not to scuff or nick the metal surfaces when

decarboning.

Valve seat

Check the valve seat.

If crack or other damage is found, replace the cylinder head.

Cylinder head distortion

Measure the cylinder head distortion (gasketed surface) at a to-

tal of 6 locations as shown.

$

09900-20803: Thickness gauge

Straight gauge

Service limit: 0.05 mm (0.002 in)

If the measurement exceeds the service limit, resurface or re-

place the cylinder head.

NOTE:

The cylinder head can be resurfaced, using a surface plate and

#400 grit wet sandpaper. Move the cylinder head in a figure

eight pattern when sanding.