LOWER UNIT 9-23

LOWER UNIT GEARS- SHIMMING AND

ADJUSTMENT

If the lower unit has been rebuilt or has had components replaced,

shimming for correct gear contact and backlash will have to be

adjusted to ensure smooth, reliable operation of gears.

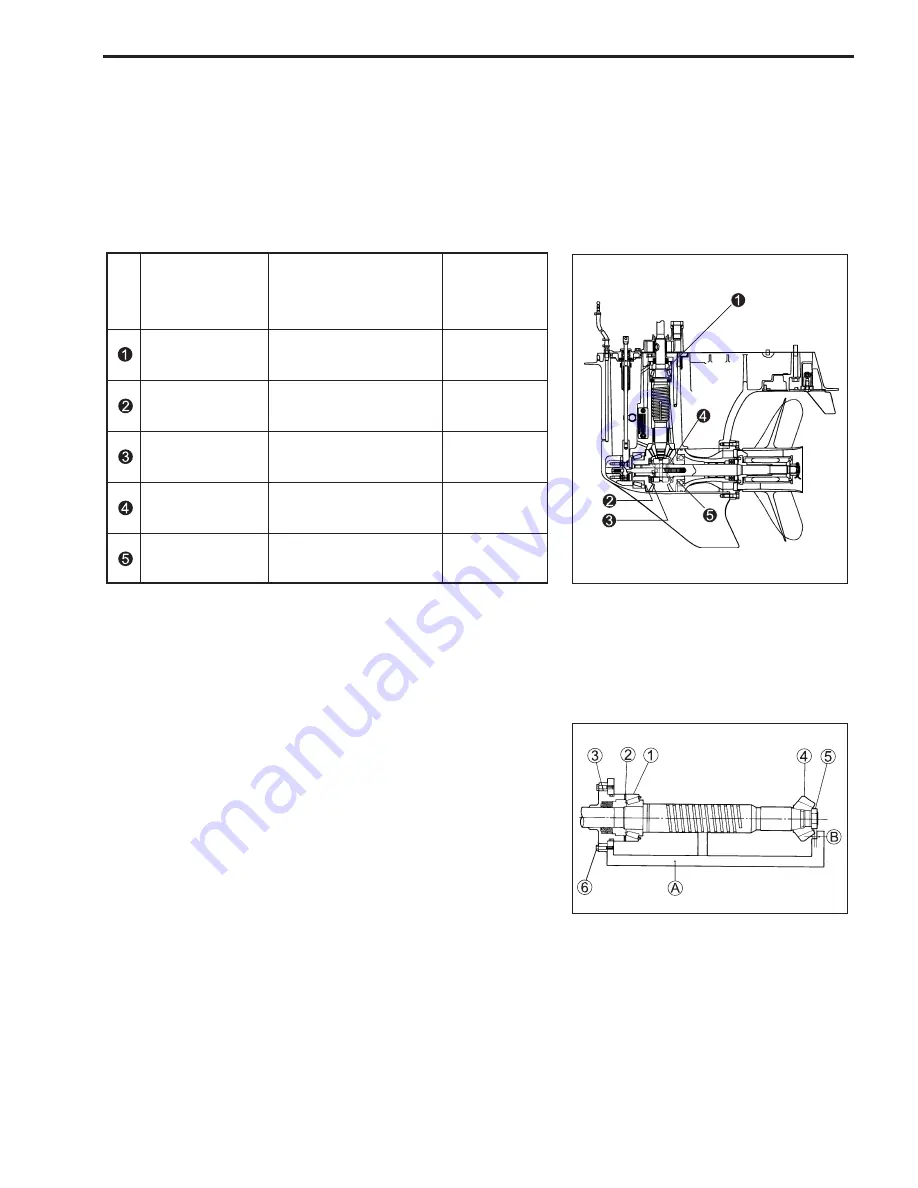

PINION GEAR BACK-UP SHIM ADJUSTMENT

1. Position the shimming gauge

A

horizontally in a vise and

tighten the vise securely.

"

09951-09010: Shimming gauge

2. Assemble the bearing outer race

1

, the back-up shim

2

and the driveshaft oil seal housing

3

to the driveshaft.

NOTE:

Use a thinner pinion back-up shim

2

than the standard shim so

that a clearance

B

exists.

3. Insert the driveshaft through the shimming gauge

A

open-

ing and then install the pinion gear

4

and the nut

5

to the

driveshaft, tighten the pinion nut.

&

&

&

&

&

Pinion nut: 100 N.m (10.0 kg-m, 72.5 lb-ft)

4. Install the oil seal housing

3

to the shimming gauge

A

with

the bolts

6

.

Numerical

index/item

Available

thickness

(mm)

Design

specification

Thickness

(mm)

Pinion gear

back up shim

0.60, 0.65, 0.70, 0.75, 0.80,

0.85, 0.90, 0.95, 1.00, 1.05,

1.10, 1.15

1.0

Forward gear

back up shim

1.0

Forward gear

thrust washer

3.0

3.0

Reverse gear

thrust washer

2.2

Reverse gear

back up shim

1.5

Shim/Washer & Mounting position

0.45, 0.50, 0.55, 0.60, 0.65,

0.70, 0.75, 0.80, 0.85, 0.90

0.9, 1.0, 1.2, 1.3, 1.4, 1.6

1.0, 1.1, 1.2, 1.3, 1.4, 1.5, 1.6