2-20 PERIODIC MAINTENANCE

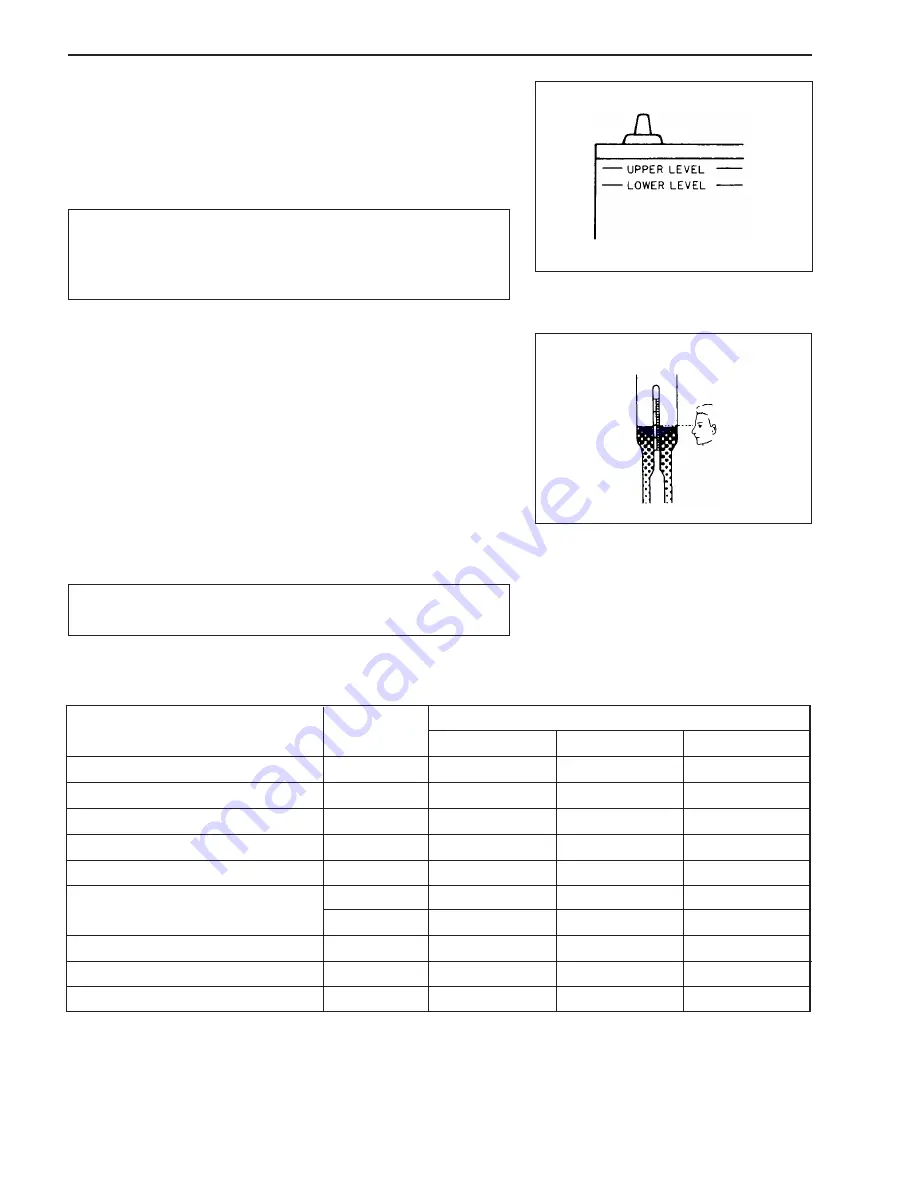

BATTERY SOLUTION LEVEL CHECK

The battery solution level should be between the UPPER level

and the LOWER level.

If the level is low, add distilled water only.

#

Once the battery has been initially serviced, NEVER add

diluted sulphuric acid, or you will damage the battery.

Follow the battery manufacture’s instructions for spe-

cific maintenance procedures.

BATTERY SOLUTION SPECIFIC GRAVITY CHECK

Measure the gravity of the battery solution by using the hydrom-

eter.

!

09900-28403: Hydrometer

Battery solution specific gravity: 1.28 at 20 °C

BOLTS AND NUTS

Inspect initially after 20 hours (1 month) and every 100

hours (6 months) thereafter.

Check that all bolts and nuts listed below are tightened to their

specified torque.

ITEM

TIGHTENING TORQUE

N.m

kg-m

lb-ft

Cylinder head cover bolt

10

1.0

7.0

Cylinder head bolt

Power unit mounting bolt / nut

Clamp bracket shaft nut

190

19.0

137.5

Gearcase bolt

Propeller nut

43

4.3

31.0

73

7.3

53.0

23

2.3

16.5

23

2.3

16.5

8 mm

8 mm

50

5.0

36.0

THREAD

DIAMETER

10 mm

6 mm

16 mm

10 mm

22 mm

8 mm

23

2.3

16.5

Intake manifold bolt / nut

Exhaust manifold bolt / nut

Flywheel bolt

10 mm

18 mm

55

55

5.5

5.5

40.0

40.0