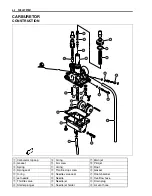

4-9 FUEL SYSTEM

AIR SCREW REMOVAL

Because harsh cleaning solvents can damage the O-ring seals

in the pilot system, the pilot system components should be

removed before cleaning.

• Use a 1/8

″

size drill bit with a drill-stop to remove the air

screw plug. Set the drill-stop 6 mm from the end of the bit to

prevent drilling into the air screw. Carefully drill through the

plug.

• Thread a self-tapping sheet metal screw into the plug. Pull on

the screw head with pliers to remove the plug. Carefully clean

any metal shavings from the area.

• Slowly turn the air screw in clockwise and count the number

of turns until the screw is lightly seated. Make a note of how

many turns were made so the screw can be reset correctly

after cleaning.

• Remove the air screw with the spring, washer, and O-ring.

• After cleaning reinstall the air screw to the original setting by

turning the screw in until it lightly seats, and then backing it

out the same number of turns counted during disassembly.

• Install new plug by tapping it into place with a punch.

CLEANING

#

• Clean all jets with a spray-type carburetor cleaner and dry

them with compressed air.

• Clean all circuits of the carburetor thoroughly – not just the

perceived problem area. Clean the circuits in the carburetor

body with a spray-type cleaner and allow each circuit to soak,

if necessary, to loosen dirt and varnish. Blow the body with

compressed air.

Drill-stop

Plug

Carburetor

body

Air screw

Some carburetor cleaning chemicals, especially

dip-type soaking solutions, are very corrosive and

must be handled carefully. Always follow the chemical

manufacturer’s instructions on proper use, handling

and storage.

Do not use a wire to clean the jets or passageways. A

wire can damage the jets and passageways. If the

components cannot be cleaned with a spray-type

cleaner, it may be necessary to use a dip-type clean-

ing solution and allow them to soak. Always follow the

chemical manufacturer’s instructions for proper use

and cleaning of the carburetor components.