6A2-28 ENGINE MECHANICAL (K9K ENGINE)

Installation

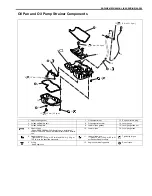

1) Clean sealing surfaces on cylinder block, upper oil pan and

lower oil pan.

2) Clean Inside of oil pan and oil pump strainer screen (1).

3) Install oil pan baffle plate to upper oil pan.

Tightening torque

Oil pan baffle plate bolt (a): 8 N·m (0.8 kg-m, 6.0 lb-ft)

4) Apply sealant “A” to cylinder block and gasket holder sealing

surface area as shown in the figure.

“A”: RHODORSEAL 5661®

1

1

(a)

[A]: Crankshaft pulley side

[B]: Flywheel side

“a”: 5 mm (0.20 in.)

“b”: 7 mm (0.27 in.)

“A”

“A”

“a”

“A”

“A”

“A”

“a”

“A”

“b”

[A]

[B]