ENGINE MECHANICAL (K9K ENGINE) 6A2-29

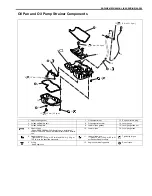

5) Install upper oil pan to cylinder block as follows.

a) Fit upper oil pan to cylinder block with new gasket.

b) Tighten upper oil pan bolts temporarily by hand.

c) Tighten upper oil pan bolts (“1” to “8”) to 6 N·m (0.6 kg-m,

4.5 lb-ft) according to numerical order in figure.

d) Tighten upper oil pan bolts (“1” to “8”) to 16 N·m (1.6 kg-m,

12.0 lb-ft) by numerical order as shown in figure.

e) Tighten upper oil pan bolts (“9” to “20”) to 6 N·m (0.6 kg-m,

4.5 lb-ft) according to numerical order in figure.

f) Tighten upper oil pan bolts (“9” to “20”) to 16 N·m (1.6 kg-m,

12.0 lb-ft) by numerical order as shown in figure.

Tightening torque

Upper oil pan bolt (a):

Tighten 6 N·m (0.6 kg-m, 4.5 lb-ft) and 16 N·m (1.6 kg-m,

12.0 lb-ft) by the specified procedure

6) Apply engine oil to O-ring, and install oil pump strainer (1) to

upper oil pan (2) with new O-ring.

Tightening torque

Oil pump strainer bolt (a): 12 N·m (1.2 kg-m, 9.0 lb-ft)

7) Install lower oil pan to upper oil pan as follows.

a) Fit lower oil pan (1) to upper oil pan.

b) Tighten lower oil pan bolts temporarily by hand.

c) Tighten lower oil pan bolts to specified torque by numerical

order as shown in figure.

Tightening torque

Lower oil pan bolt (a):

Tighten12 N·m (1.2 kg-m, 9.0 lb-ft) by the specified proce-

dure

8) Install engine mounting bracket bolts (1).

Tightening torque

Engine mounting bracket bolt (a):

40 N·m (4.0 kg-m, 29.0 lb-ft)

9) Install accessory bracket bolt (2).

Tightening torque

Accessory bracket bolt (b):

28 N·m (2.8 kg-m, 20.5 lb-ft)

“2”

“20”

“18”

“16”

“14”

“6”

“12”

“10”

“8”

“4”

“3”

“7”

“9”

“11”

“5”

“13”

“15”

“17”

“19”

“1”, (a)

1

2

(a)

“22”

“20”

“18”

“16”

“14”

“12”

“10”

“8”

“6”

“4”

“2”

“1”, (a)

“3”

“5”

“7”

“9”

“11”

“13”

“15”

“17”

“19”

“21”

1, (a)

2, (b)

1, (a)