3-62 ENGINE

GEARSHIFT FORK

GEARSHIFT FORK-TO-GROOVE CLEARANCE

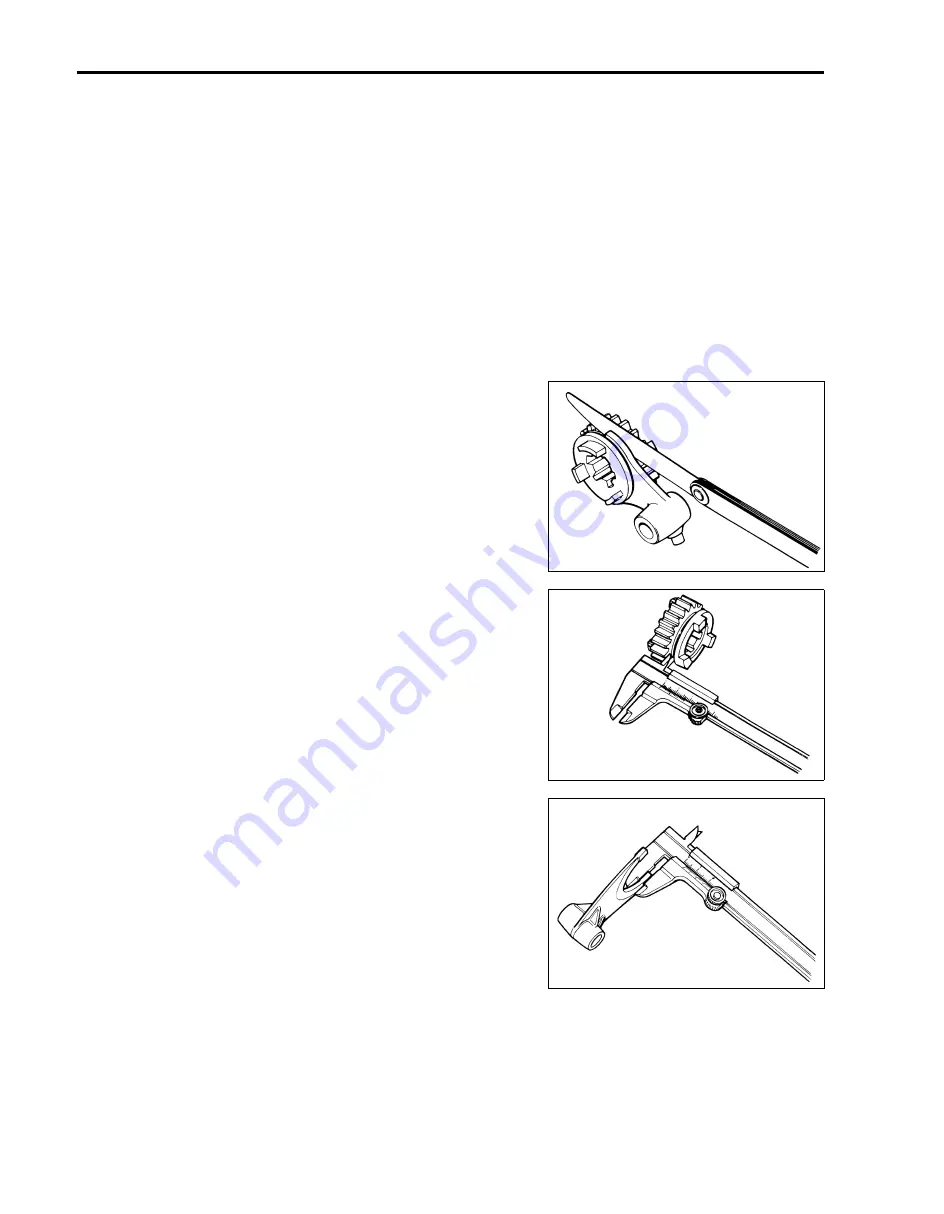

Using a thickness gauge, check the shifting fork clearance in the

groove of its gear.

The clearance for each of the two shifting forks plays an impor-

tant role in the smoothness and positiveness of shifting action.

If the clearance exceeds the limit, replace the fork or its gear, or

both.

&

Shift fork to groove clearance:

Standard: 0.10 – 0.30 mm (0.004 – 0.012 in)

Service Limit: 0.50 mm (0.020 in)

%

09900-20803: Thickness gauge

SEARSHIFT FORK GROOVE WIDTH

• Measure the gearshift fork groove width using the vernier cali-

pers.

&

Shift fork groove width:

Standard (Reverse):

5.50 – 5.60 mm (0.217 – 0.220 in)

(High): 5.50 – 5.60 mm (0.217 – 0.220 in)

%

09900-20101: Vernier calipers

GEARSHIFT FORK THICKNESS

• Measure the gearshift fork thickness using the vernier cali-

pers.

&

Shift fork thickness:

Standard (Reverse):

5.30 – 5.40 mm (0.209 – 0.213 in)

(High): 5.30 – 5.40 mm (0.209 – 0.213 in)

%

09900-20101: Vernier calipers

Summary of Contents for LT-A700X 2004

Page 25: ...2 8 PERIODIC MAINTENANCE INTAKE SIDE ...

Page 26: ...PERIODIC MAINTENANCE 2 9 EXHAUST SIDE ...

Page 46: ...PERIODIC MAINTENANCE 2 29 ...

Page 59: ...3 8 ENGINE Remove the engine from the right side ...

Page 133: ...3 82 ENGINE Pull the rope and check that the ratchet is pushed out ...

Page 155: ......

Page 263: ......

Page 301: ...7 20 COOLING AND LUBRICATION SYSTEM EXHAUST SIDE INTAKE SIDE ...

Page 302: ......

Page 312: ...CHASSIS 8 9 REAR CARRIER Remove the rear carrier 1 ...

Page 386: ......

Page 420: ...ELECTRICAL SYSTEM 9 33 HEADLIGHT INSTALLATION Head light coupler Head light R Adjusting point ...

Page 453: ...10 26 SERVICING INFORMATION Rear box Rear fender Right mud guard Left mud guard ...

Page 477: ......

Page 480: ...Prepared by September 2004 Part No 99500 46060 01E Printed in U S A 472 ...