22

Operating Maintenance Installation CLASSIC PIZZA 860005-02

• When the oven sections are separated from each

other they can be carefully lifted down and moved

to the place of assembly.

• Use the planks from the loading pallet and place

these on the forks of the truck as spacers to protect

the oven door (Fig. 13).

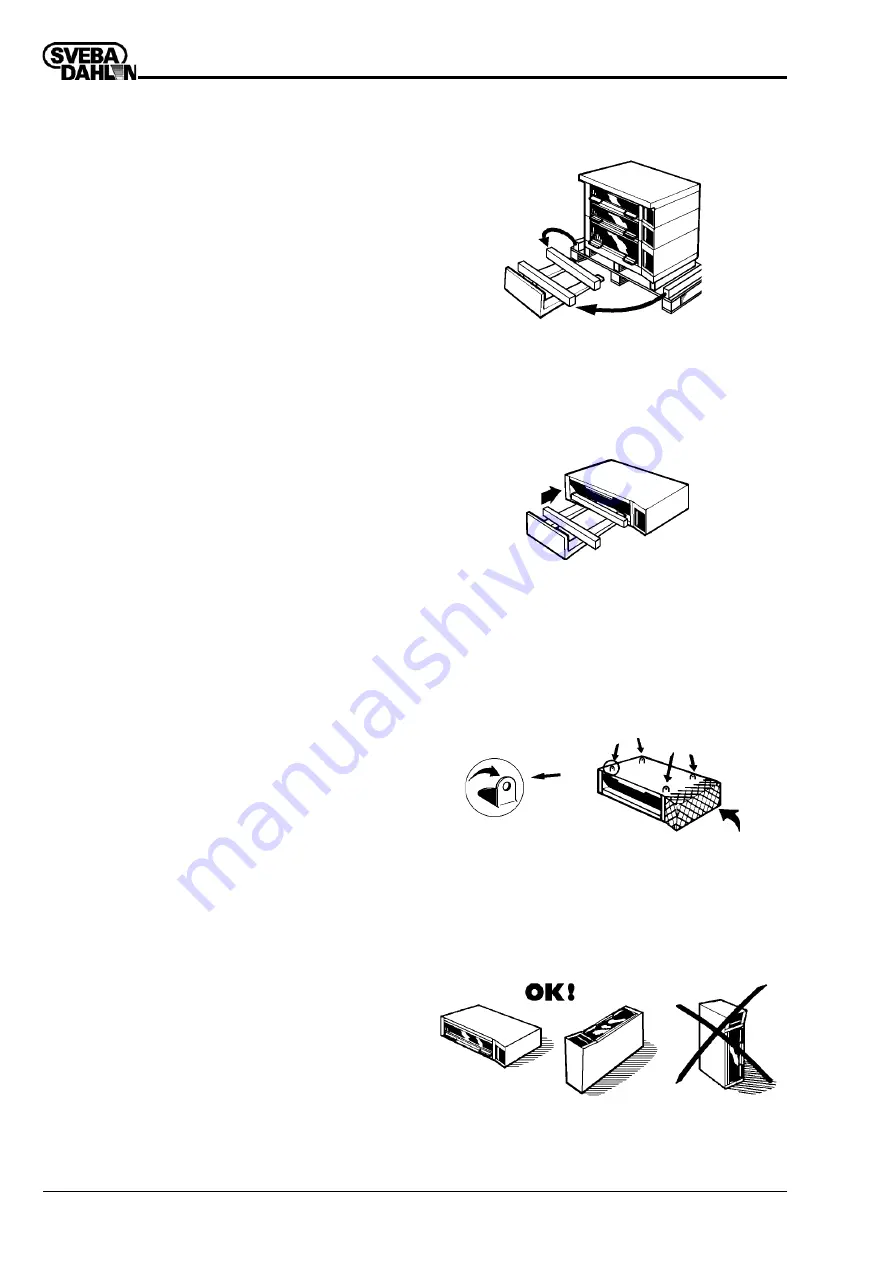

• Now lift off one section at once (Fig. 14).

• The sections can also be lifted in their lifting

hooks, which are partially concealed under the

insulation. The hooks at the front of the oven roof

are to be turned up 90° before use (fig. 15).

• Do not put down or carry an oven section with the

short side down (Fig. 16). The oven

has

no reinforcements for this type of strain, and there

is a risk for deformation.

If the section is put down on the back-piece, make

sure that the underlayer is flat. A spot load such

as a door threshold can easily crack the back-piece.

Observe

care with protruding parts such as the damper or

the connection head of the element in the

distribution box.

• When all parts are lifted into position the assembly

of the oven can begin.

Fig. 13 Lifting of the parts of the oven.

Use the planks from the loading pallet when lifting off the

oven section.

Fig. 14 Lifting of section with fork-lift truck.

Watch out for the door and the window! The planks should be

at least 75 mm high. Never lift more than one oven chamber

at once in this way!

Fig. 15 Lifting of section in lifting hooks.

Never lift or pull on the area of the oven which is marked!

Fig. 16 Never put an oven section down on its side!

Watch out for extruding parts such as the damper or

elements.