23

Operating Maintenance Installation CLASSIC PIZZA 860005-02

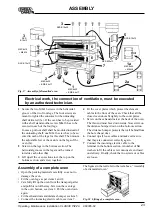

ASSEMBLY

3

RXS B10x32

RXS B10x13

M6S 6x16

+ M6M 6

3

RXS

B10x13

4

5

RXS B10x13

2a

1a

M6S 8x20

+ M6M 8

7

6

6

RXS B10x13

1

M6S 8x20

+ BRB 8.4x17

2

M6S 8x20

+ BRB 8.4x17

1

Secure the two M8x16 screws in the helicoidal

groove of the two front legs. The four screws are

meant to tighten the consoles for the unloading

shelf delivered (1a). If the oven has to be provided

with a shelf stand another screw M8x16 has to be

secured in each of the four legs.

In case a pull out shelf shall be mounted instead of

the unloading shelf, one M8x16 screw has to be se-

cured in each of the legs for this shelf. Then mount

the adjustable feet or the castors on the legs of the

oven (1a).

2

Screw on the legs in the bottom section. The

helicoidal grooves in the legs must be turned

towards each other (

2a

).

3

Lift up all the oven sections incl. the top on the

bottom section, and screw together.

4

Fit the cover plates which protect the element

cables in the front of the oven. Check that all the

closed oven doors fit tightly to the cover plates.

5 Screw on the exhaust ducts at the back of the oven.

The thin end must face downwards. Now screw on

the distance bumper down on the bottom section.

The distance bumper protects the wall behind from

the hot exhaust duct.

6

Connect up all loose cables and make extra sure

that they are connected correctly again.

7

Connect the incoming electric cable to the

terminal in the bottom section. A number of flat

washers to fit the cable screw unions are enclosed

on delivery. Finally, check that no screws or cables

are loose.

Fig. 17 Assembly of dismantled oven.

Electrical work, the connection of ventilation, must be executed

by an authorized technician.

Assembly of a complete oven

Fig. 18 Lifting of a complete oven.

The figures in the text refer to the text above, ”Assembly

of a dismantled oven”.

• Open the packing materials carefully so as not to

damage the oven.

• Fit the oven legs as per items 1 and 2.

• Carefully lift up the oven from the transport pallet

and pull this out of the way. Screw on the oven legs

in the oven bottom, see item 2. Put the oven down

again.

• Fit the exhaust ducts and distance bumper, see item 5.

• Connect the incoming electric cable, see item 7.