Summary of Contents for DF 115 P

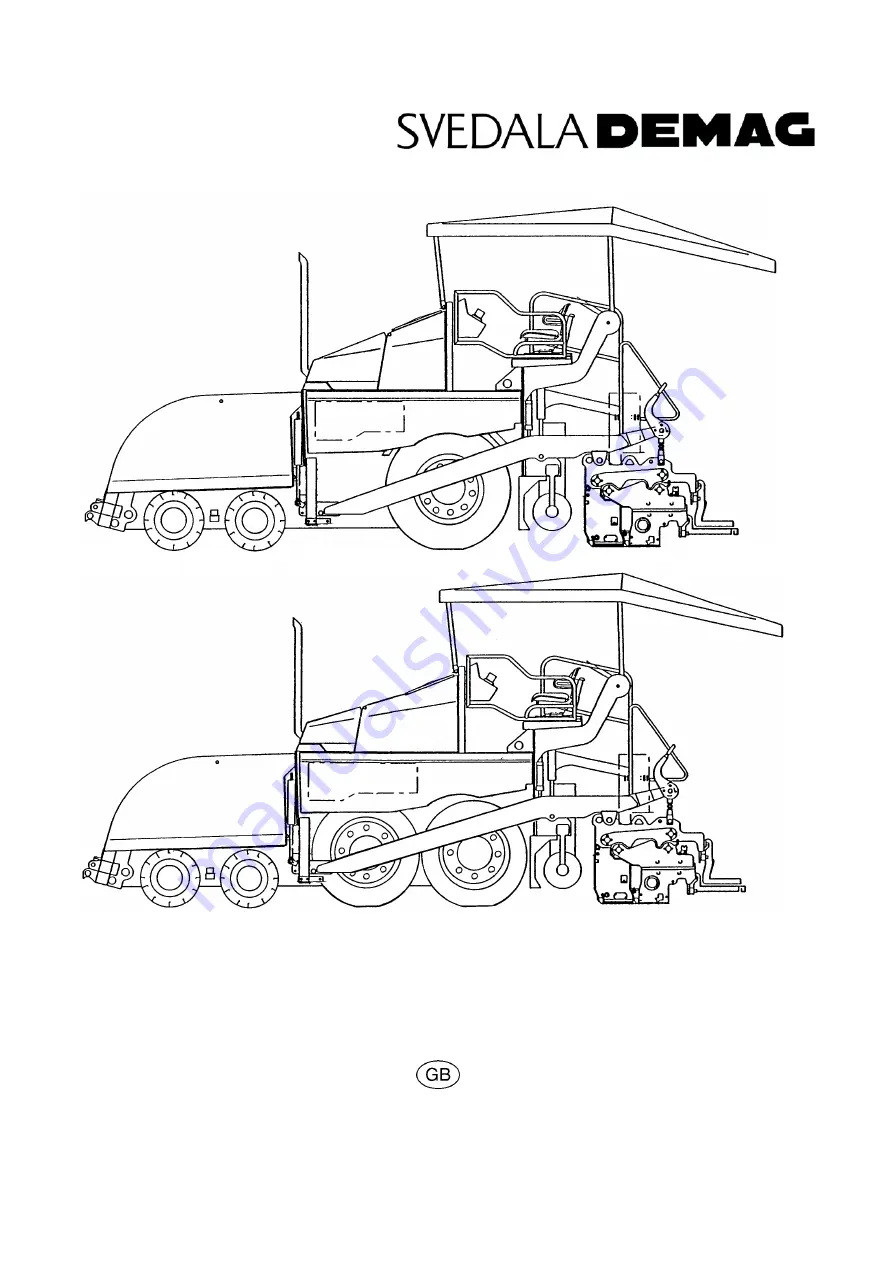

Page 1: ...Operating instructions 02 0103 Paver Finisher 900 98 06 33 DF 115 P DF 135 P ...

Page 2: ......

Page 4: ......

Page 10: ......

Page 12: ......

Page 42: ...D 4 D DF115_135P GB 4 66 01 03 Element2_KC cdr 7 9 12 11 6 A 9a 10 5 8 13 ...

Page 44: ...D 6 D DF115_135P GB 6 66 01 03 Element2_KC cdr 7 9 12 11 6 A 9a 10 5 8 13 ...

Page 104: ......

Page 152: ......