F 18

F

F

_

DF1

15_13

5P_G

B.

fm

.D

18-

42 -

0

1.

0

3

Cooling system engine and hydraulics (1.5)

The machine is fitted with water, hydraulic and charged air coolers.

Water cooler

Always check the coolant (water) level

when cold. Ensure there is sufficient an-

tifreeze and anti-corrosion agent (-

25°C).

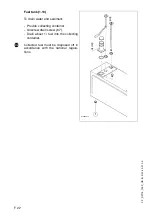

The perfect level is 6 cm below the seal-

ing face of the seal cover.

System is pressurised when warm! Risk

of scalding when opening!

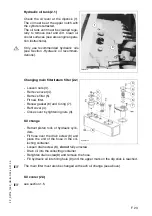

Hydraulic cooler

The finisher is fitted with a hydraulic oil

cooler as standard. This cooler is of de-

cisive importance for the operating relia-

bility of the complete hydraulic system.

A fouled oil cooler can cause the follow-

ing damage:

- Inadmissibly high oil temperature

- Quicker oil ageing

- Oil thinning

- Loss of lubricity and in turn hear wear on seals, O-rings, pumps and motors.

- Leakages

- Regularly check the hydraulic oil cooler, cooling coil and engine cooling for fouling.

- Clean engine cooling system if necessary.

Only carry out cleaning with the engine cooled down!

Kühl115.jpg, Kühl.tif

6 c

m

Summary of Contents for DF 115 P

Page 1: ...Operating instructions 02 0103 Paver Finisher 900 98 06 33 DF 115 P DF 135 P ...

Page 2: ......

Page 4: ......

Page 10: ......

Page 12: ......

Page 42: ...D 4 D DF115_135P GB 4 66 01 03 Element2_KC cdr 7 9 12 11 6 A 9a 10 5 8 13 ...

Page 44: ...D 6 D DF115_135P GB 6 66 01 03 Element2_KC cdr 7 9 12 11 6 A 9a 10 5 8 13 ...

Page 104: ......

Page 152: ......