D 9

D DF1

1

5

_135P.

G

B 9

-66

-

01

.0

3

Pos. Designation

Brief description

16

Electrical transmis-

sion shifting (

&

)

This shifts the transmission.

16a

(O)

Reversing

shift

conveyor

The conveyor’s direction of conveyance can be changed over

(to the opposite direction) separately for both halves of the

conveyor. This often has to be done to move back material

from just in front of the auger. This allows e.g. material losses

during transport operations to be prevented. The conveyor

moves a distance of approx. 1 metre towards the hopper.

If necessary, the switch can be pressed as often as re-

quired so that the conveyor can move further in the op-

posite direction.

17

Conveyor,

left/right

auto:

switched on with drive lever and continuously controlled

by the material limit switch

stop:

Off

manual:

permanently switched on (with full feed capacity,

without material control)

-

To automatically operate the conveyor via the remote

control (

&

), both switches must be set to ”auto”.

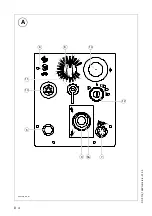

18

Tamper

(screed-specific)

auto:

switched on with drive lever switched off when at a

standstill

stop:

completely switched off

manual:

permanently switched on

As a rule, ”auto” is used for paving.

$

When the switch is set to ”manual” during paving, it

must be set to ”stop” when at a standstill. Otherwise, ex-

cessive compacting occurs!

Speed control (see the section “Speed regulator,

tamper”).

19

Vibration

(screed-specific)

Operation and application: see switch (Tamper).

Speed control (see the section “Speed regulator, vibration”).

20

Screed charging/

relieving device

For charging/relieving the screed to influence traction and the

compacting ratio.

A:

Relieving (screed ‘lighter’)

B:

No function (floating position)

C:

Charging (screed ‘heavier’)

-

Pressure regulating valve (93) must be used to set the

charging/relieving factor.

-

For ”screed stop with pretensioning”, position

A

must be

selected (see switch (21) and pressure regulating valve

(93a)).

A

B

C

Summary of Contents for DF 115 P

Page 1: ...Operating instructions 02 0103 Paver Finisher 900 98 06 33 DF 115 P DF 135 P ...

Page 2: ......

Page 4: ......

Page 10: ......

Page 12: ......

Page 42: ...D 4 D DF115_135P GB 4 66 01 03 Element2_KC cdr 7 9 12 11 6 A 9a 10 5 8 13 ...

Page 44: ...D 6 D DF115_135P GB 6 66 01 03 Element2_KC cdr 7 9 12 11 6 A 9a 10 5 8 13 ...

Page 104: ......

Page 152: ......