3

Make sure that the distance to the nearest pulley is sufficiently large so that the rope cannot

mount the drum flange. The line must be wound evenly on to the drum.

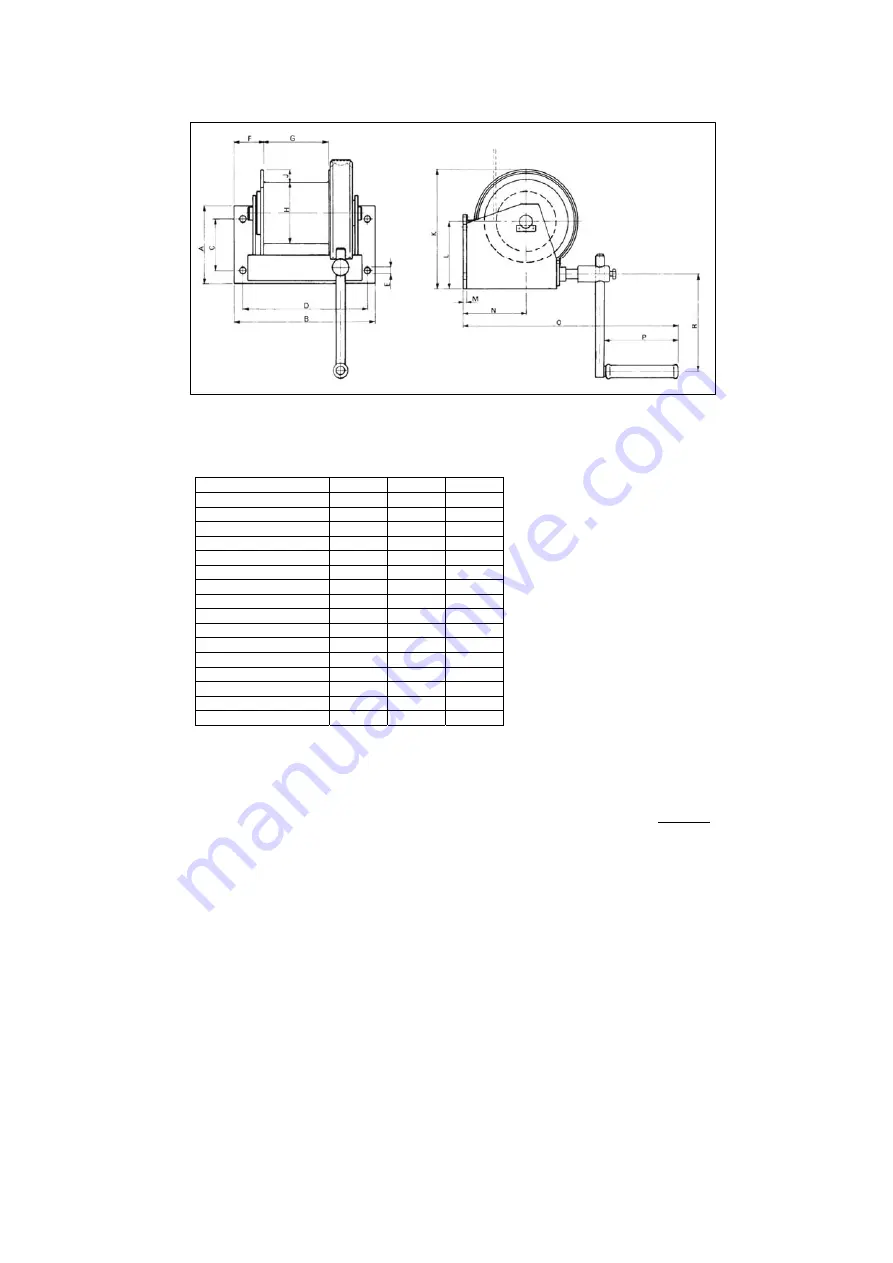

Fig. 2 Dimensioned sketch

Dimensions table

Model

6211A

6113A

6114A

Dimension A mm

157 180 180

Dimension B mm

210 320 350

Dimension C mm

100 120 120

Dimension D mm

183 280 320

Dimension E dia. mm

14 17 17

Dimension F mm

45 63 63

Dimension G mm

71 150 170

Dimension H dia. mm

100 140 140

Dimension J mm

28 28 52

Dimension K mm

225 285 332

Dimension L mm

132 164 189

Dimension M mm

4 8 10

Dimension N mm

115 150 177

Dimension O mm

350 463 540

Dimension P mm

105 145 145

Dimension R max mm

225 360 360

Function testing

Attach a load (up to maximum load) and raise approx. 0.5 m by turning the crank clockwise. Check

that the load is held where it is by the brake without letting go of the crank. Then lower the load in

stages without fully letting go of the crank. Then check the functions, raising, lowering and load

holding (releasing the crank). When the crank is released it may rotate backwards by maximum a

half turn. The brake must then hold the load without slipping.

Summary of Contents for 6113A

Page 5: ...5 Appendix Spare parts drawing with lubricating points NB 2009 03 08 ...

Page 10: ...10 Bilaga Reservdelsritning med smörjställen NB 2009 03 08 ...

Page 15: ...15 Vedlegg Oversikt over reservedeler med smørepunkter NB 2009 03 08 ...

Page 20: ...20 Liite Varaosapiirros voitelukohtineen NB 08 03 09 ...