10278L

SW-Stahl GmbH

An der Hasenjagd 3

D-42897 Remscheid

Tel. +49 (0) 2191 / 46438-0

Fax +49 (0) 2191 / 46438-40

E-Mail: info@swstahl.de

12

11.

OPERATION ANOMALIES, CAUSES,

SOLUTIONS

Operation

anomalies

Causes

Solutions

The machine

does not work

Check the

connection to

the compressed

air system

Connect the

machine to the

local pneumatic

system through the

quick connection

equipped

The two arms do

not run properly

along the

columns

Dust and dirt on

the columns

Clean the columns

and the sliding

parts with a

dry rag,

NEVER

LUBRICATE WITH

GREASES OR OILS

The piston’s shaft

after moving

forward does not

keep the position

and goes back

There is an

air leak in the

cylinder

Contact customer

service to repair

the cylinder

12. MACHINE IDLED FOR A LONG PERIOD

Following the under mentioned instructions when the

machine 10278L is idled for a long period:

- Disconnect the pneumatic feeding hose.

- Discharge the air inside the cylinder.

- Lubricate the compressed air inlet.

dismounting the shock absorbers from the car.

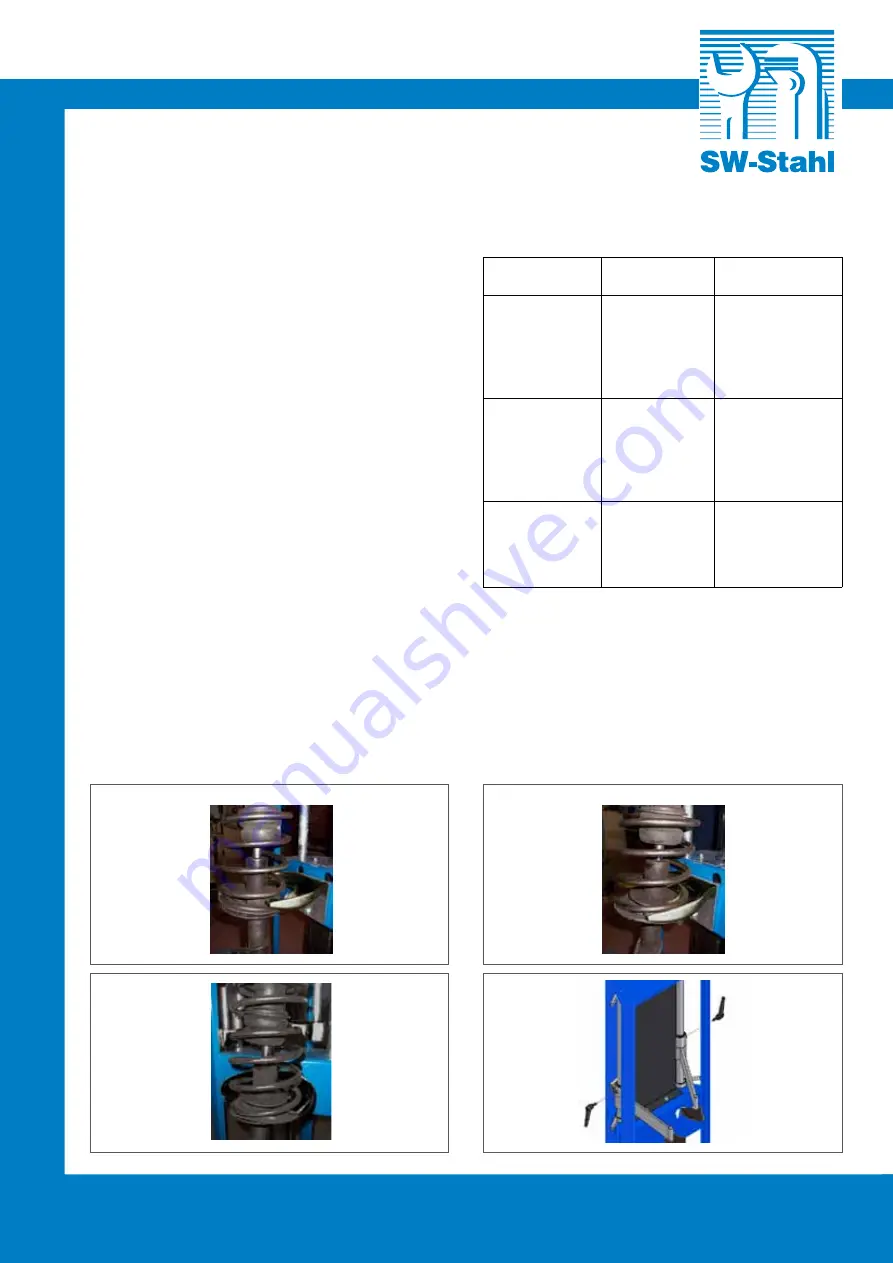

Positioning the shock absorbers on the lower bracket in

the first coil (fig. 1), rotate the shock absorber and lock

it in the bracket in the maximum slipping point (fig. 2).

Put the small arms near the spring and insert the upper

vices in the first coil available (see fig. 3).

After having found the right position of the spring on

the bracket and after having adjusted the upper vices,

block the adjustable arms (fig.4) locking the screws

behind the case with the key supplied.

Compress the spring using the foot control lever only

to release the pressure that the spring it-self exert on

the cap.

Do not compress the spring completely (see fig.5).

Remove the blocking cap form the shock absorber

unscrewing the nut. Discharge the compression of the

spring and replace the old shaft with the new one.

10.2 Assembling

For assembling make the contrary operations of the

disassembling. Put the new spring in the same position

where the old one was. Press the foot control lever in

order to make the spring stuck to the blocking cap.

Block the cap to the shaft of the shock absorber screwing

the proper nut. Now the shock absorber is mounted,

use the foot control lever to release completely the

spring, then move the arms on the outside and remove

the shock absorber now reassembled thanks to the

machine 10278L.

1

2

3

4