10278L

SW-Stahl GmbH

BE

D

IE

N

UN

G

S

A

N

L

E

IT

UN

G

13

13. ORDINARY MAINTENANCE

Periodically (every 3 months, or when it is necessary),

clean the sliding columns form dust, earth etc. with a

little bit of lithium-base grease.

NEVER LUBRICATE the sliding parts

(columns) with GREASES, OILS,

DETERGENS or SVITOL.

14. EXTRAORDINARY MAINTENANCE

Extraordinary maintenance operations are to be carried

out by qualified personnel; it is advisable to refer to

authorized dealers for repairing operations and original

spare parts.

15. ACCESSORIES

NOT INCLUDED

15.1 Vice

15.2 Disassembling using - Vice

Always refer to the car manifacturer’s service

instructions or proprietary manual to estabilish the

current procedures and data. This product information

sets details of the applications and the use of the tools

only with the purpose of a generic guide.

It is advisable to unlock the nuts of shock absorbers’

cap before using the machine 10278L in order to easy

working operations. Some automotive manufacturers

prescribes to unlock the clamp nuts of the caps before

dismounting the shock absorbers from the car.

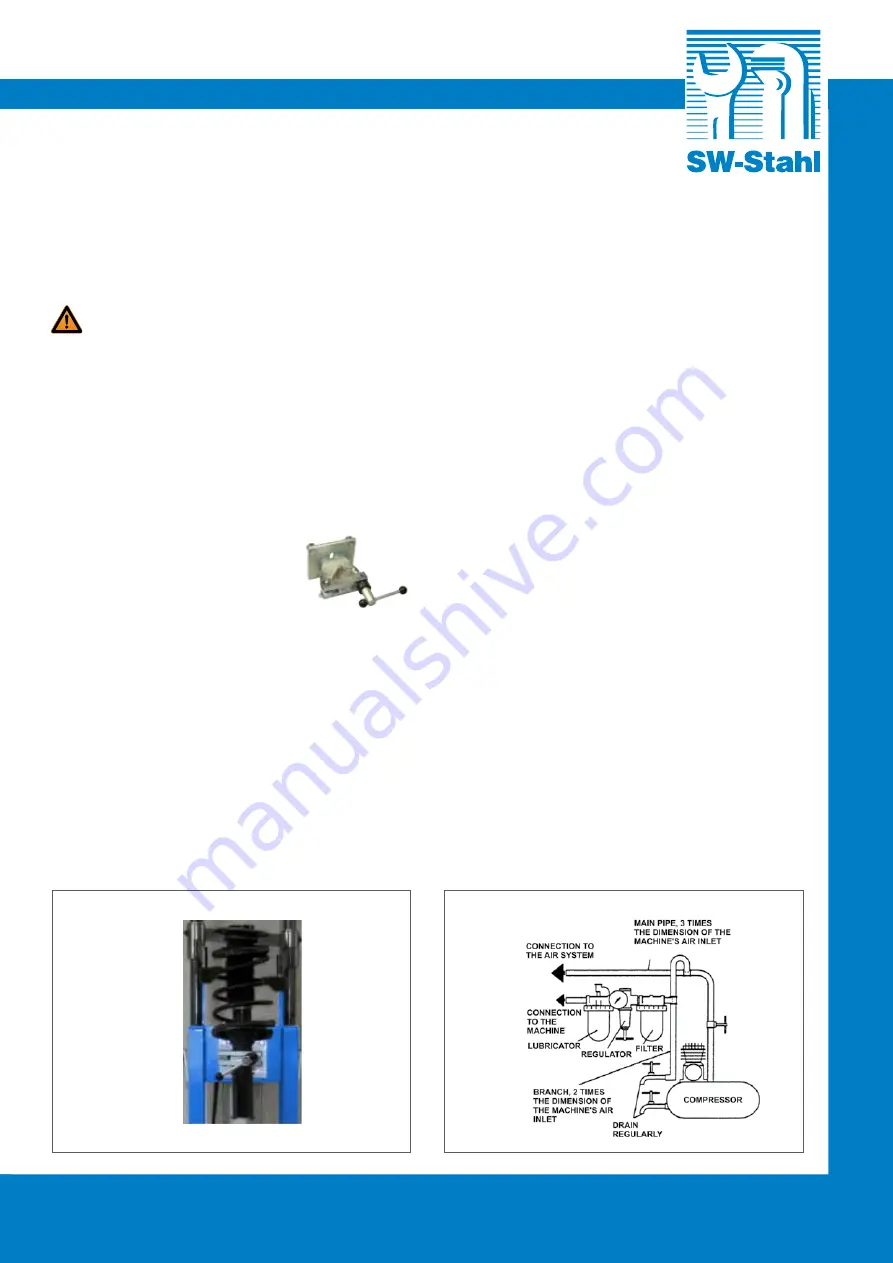

Block the strut of the shock absorber inside the vice in

order to center it on the machine (see fig. 5).

Put the small arms near the spring and insert the upper

vices in the first coil available.

After having found the right position of the spring on the

vice and after having adjusted the upper vices, block

the adjustable arms (fig.4) locking the screws behind

the case with the key supplied.

Compress the spring using the foot control lever only

to release the pressure that the spring it-self exert on

the cap.

Remove the blocking cup form the shock absorber

unscrewing the nut. Discharge the compression of the

spring and replace the old shaft with the new one.

15.3 Assembling using vice

For assembling make the contrary operations of the

disassembling. Put the new spring in the same position

where the old one was. Press the foot control lever in

order to make the spring stuck to the blocking cap.

Block the cap to the shaft of the shock absorber

screwing the proper nut.

Now the shock absorber is mounted, use the foot

control lever to release completely the spring, then

move the arms on the outside and remove the shock

absorber now reassembled thanks to the machine

10278L.

16. LUBRIFICATION OF THE DEVICE

Always use of an air line lubricator with these tools.

We recommend the following Filter-Lubricator-

Regulator Unit.

6

5