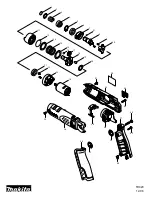

S3284

BEDIENUNGSANLEITUNG / INSTRUCTION MANUAL

SW-Stahl GmbH

Tel. +49 (0) 2191 / 46438-0

An der Hasenjagd 3

Fax +49 (0) 2191 / 46438-40

D-42897

Remscheid E-Mail:

info@swstahl.de

1. Before operation, put a few drops of acid- and resin-free pneumatic

oil in the air inlet of the tool.

2. Before connecting the tool, clean the couplers and hoses by blasting them

briefly with air. Make sure hose and couplers have a sufficient diameter.

Note: The diameters of compressed air hoses are usually chosen too small, never

too large! At the front of this operating manual you will find a table containing

the recommended minimum hose diameters.

3. The operating pressure measured under load at the tool air inlet should be 6.3 bar.

A higher pressure means greater wear and can cause damage to the tool. A fall in

pressure to 5.5 bar means extreme loss of power.

4. Good air quality is vital for any pneumatic tool. The air must be clean, dry and

lubricated. The best solution is a complete maintenance unit comprising an air

filter, regulator and oil-fog lubricator which is no more than 6-8 m away from the

tool. The oiler should be set to 3-6 drops per minute (inspection glass). The

length of the hose between tool and maintenance unit should not exceed 8 m.

5. We recommend using a central oiler unit for optimum tool lubrication. Up to 80%

oil can be saved, which also improves the quality of the air inhaled by the user

of course, since no excess oil is expelled to the air.

6. The hammer mechanism of the impact screwdriver should be lubricated lightly

after 60 working hours at the latest. Too much grease will impair the power of

the impact screwdriver since the hammer mechanism will become sticky.

7. If the tool is not to be used for a longer period, it must be lubricated thoroughly

before storage. Before re-use, please heed points 1 and 2.

S3275/S3276/S3277/S3278:

8. The direction of rotation is adjusted by moving the control knob.

Clockwise = F / Anti-clockwise = R.

9. Output can be adjusted in three stages both for clockwise and

anti-clockwise direction of rotation using the control dial.

S3279/S3280:

8. The direction of rotation is adjusted using the control dial on

the left. Clockwise = F / Anti-clockwise = R.

9. Output can be adjusted in three stages both for clockwise and

anti-clockwise direction of rotation using the control dial on the right.

S3284:

8. Output and direction of rotation are adjusted by turning the

lever. Clockwise = F / Anti-clockwise = R.

9. Output can be adjusted in three stages for clockwise and

one stage for anti-clockwise direction using the lever.

S3281/S3282/S3283:

8. The direction of rotation can be adjusted on the ratchet head.

Clockwise = F / Anti-clockwise = R.

Commissioning: