– 7 –

Assembling Components

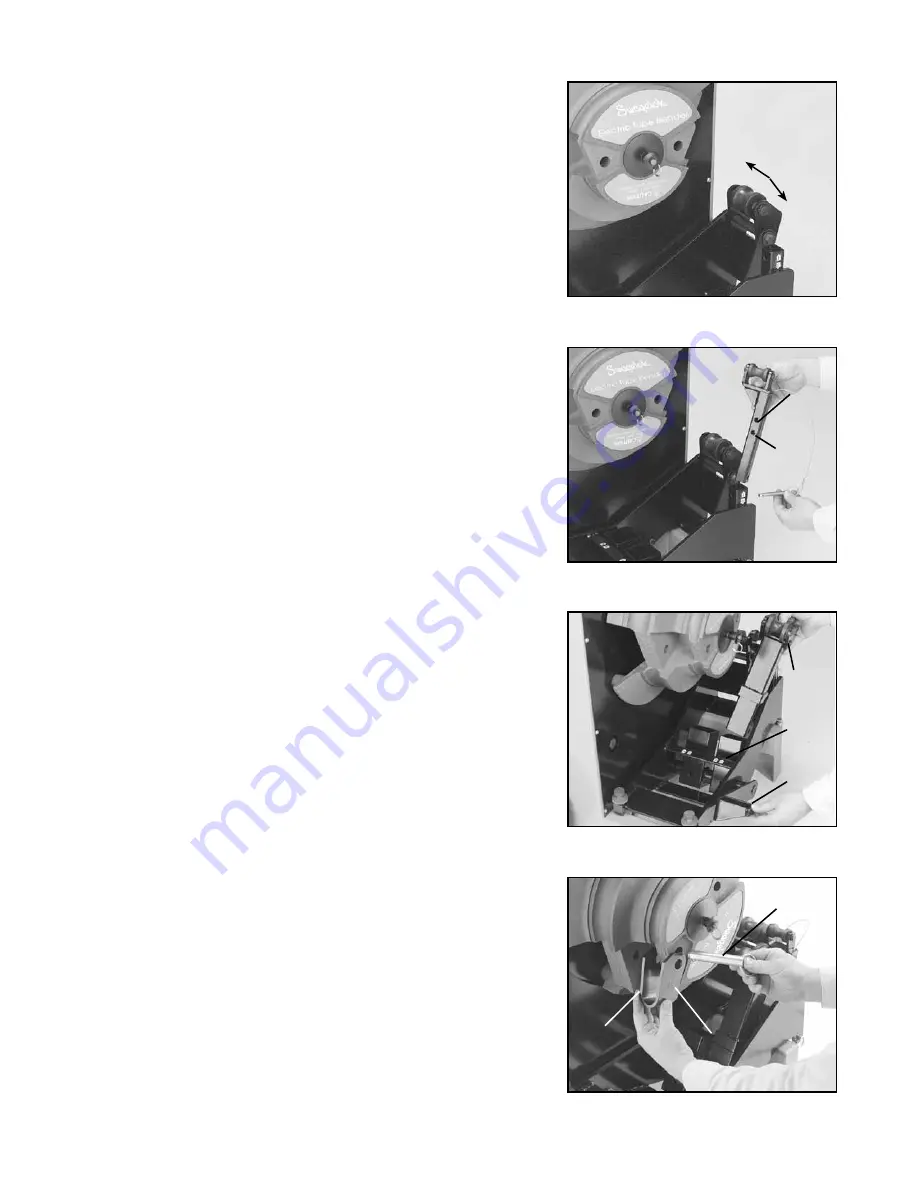

1. Select and install proper tail rollers. To bend 1 1/2 in. (38 mm) OD

tubing, use the fixed tail roller in the up position. For 2 in. (50 mm) OD

tubing, use the fixed tail roller in the down position. (See Figure 1.)

To bend 1 in. (25 mm) OD tubing, use the 1 in. (25 mm) removable tail

roller, securing pin in lower pin hole (up position). For 1 1/4 in. (32

mm) OD tubing, use the 1 1/4 in. (32 mm) removable tail roller, securing

pin in upper pin hole. Align roller with the inside of the unit. (See Figure

2.)

2. Select proper roller tower; the size is indicated on roller tower. To install,

lift and hold the handle lock. Insert the roller tower into proper bridge

opening so that the size indicator faces you. Allow roller tower to lean

against tail roller. (See Figure 3.)

3. Select proper tube clamp; the size is indicated on clamp face. Locate

the tube size on the bend shoe, and attach the tube clamp with pin,

making sure the size identification faces out. (See Figure 4.)

4. Make sure the circuit breaker is switched to the ON position and the

EMERGENCY STOP button is not engaged.

5. Plug the unit into an appropriate power source. The display on the

pendant will illuminate.

Figure 4

Pin

Tube

Clamp

Size

Indicator

Figure 2

Upper

Pin Hole

1 1/4 in.

(32 mm)

Lower

Pin Hole

1 in.

(25 mm)

Figure 3

Roller

Tower

Size

Indicator

Roller

Tower

Label

Location

Handle

Lock

Figure 1

Up Position

1 1/2 in.

(38 mm)

Down

Position

2 in.

(50 mm)

Summary of Contents for MS-TBE-1 series

Page 1: ...Electric Tube Bender User s Manual www swagelok com ...

Page 15: ... 15 ...