12

VAR

Swegon reserves the right to alter specifications.

20111011

www.swegon.com

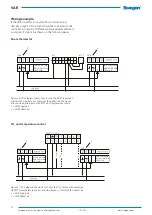

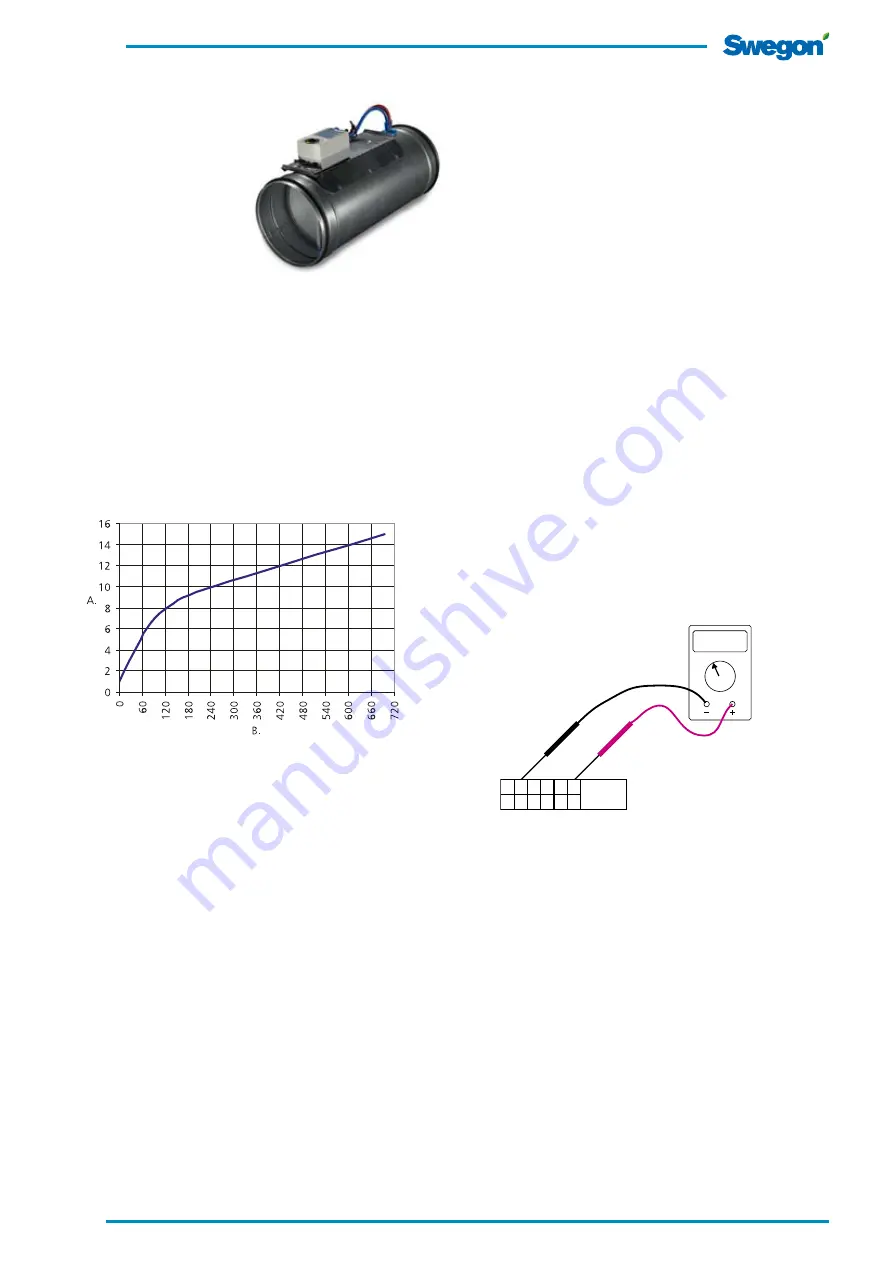

Figure 24. Shows the calibration time diagram.

A = Calibration no.

B = Time after energizing (min).

3,52 V

V DC

1

2

8

9

GLB181.1E/3

G G0

YC UC

6

Y1

7

Y2

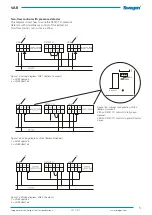

Figure 25. Shows how to connect a voltmeter for checking the

true value.

Forcing the commissioning damper to the fully

closed position:

Fit a jumper on G0 (black cable marked 2) with Y2

(orange cable marked 7). The actuator should close for a

maximum period of 150 seconds.

To force the commissioning damper to the fully

open position:

Fit a jumper on G0 (black cable marked 2) with Y1 (violet

cable marked 6). This is most easily done by disconnecting

the grey cable for the control signal marked 9.

To override with the AST setting instrument

The Y signal can also be set from the AST 10 hand-held

micro terminal. Press Y button and change the signal to

10 V with the – or + keys on the side of the display. To

acknowledge by pressing SET. When you disconnect the

Setting instrument, you also remove the means of overrid-

ing the system.

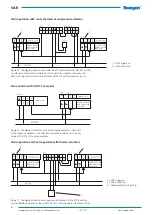

The VAR 4 as a constant-flow controller

When the VAR 4 is to be used as a constant flow

controller,this can be done in two ways . It is appropriate

to use the min. flow setting as the set point for the con-

stant airflow. 24 V AC only should be connected to the

cable pair 1 and 2. You can also use the max. airflow set-

ting, however in this case you must make a short circuit

between 2 and 3, see under Checking the max. airflow.

Important!

The release button on the unit must not be used when the

unit is energized. If this occurs, the controller will lose its

positioning capability and you will have to de-energize the

unit for at least five seconds to remedy the situation. If you

want to test or force the commissioning damper, use the

jumper connections shown below or use the AST 10 hand-

held micro terminal.

Checking the min. flow:

If possible, zero volt is transmitted from the room unit or the

main control system. If this possibility is lacking, then discon-

nect YC (grey cable, marked 8). Measure the pressure in the

pressure tapping and calculate the airflow using the K-factor

for the relevant size. Check also the max. airflow.

Regulating the commissioning damper to max. flow:

If possible, 10 volt is transmitted from the room unit or

the main control system. If this possibility is lacking, then

disconnect YC (grey cable, marked 8), fit a jumper on G0

(black cable marked 2) with Y2 (orange cable marked 7)

and Y1 (violet cable marked 6).

VAR 4

Checking the performance

Start

After energizing the system, the VAV unit calibrates the

pressure sensor as illustrated in the diagram below. Each

calibration takes 90 seconds and the unit is then idle. This

means that the user should not precision adjust the min.

and max. airflows with the AST 10 hand-held micro termi-

nal, if required, until after three hours after energizing to

avoid that the unit is idle too often. There is no in-opera-

tion indicator that shows that zero calibration is in progress.

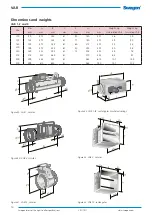

To change the settings

The min./max. airflow should be calculated and set as

follows:

Q

max

% required max. airflow (Q

max

) divided by nominal airflow

(Q

nom

).

Q

min

% required min. airflow (Q

min

) divided by nominal airflow

(Q

nom

).

Example:

VAR, dim. Ø160, required min./max. airflows: 51/119 l/s.

Q

max

% Q

max

/ Q

nom

= 119/170 = 0.70 = 70%

Q

min

% Q

min

/ Q

nom

= 51/170 = 0.30 = 30%

Q

nom

can be read in Table 1 on page 9.