8

VAR

Swegon reserves the right to alter specifications.

20111011

www.swegon.com

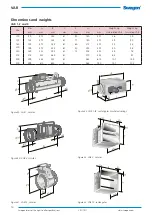

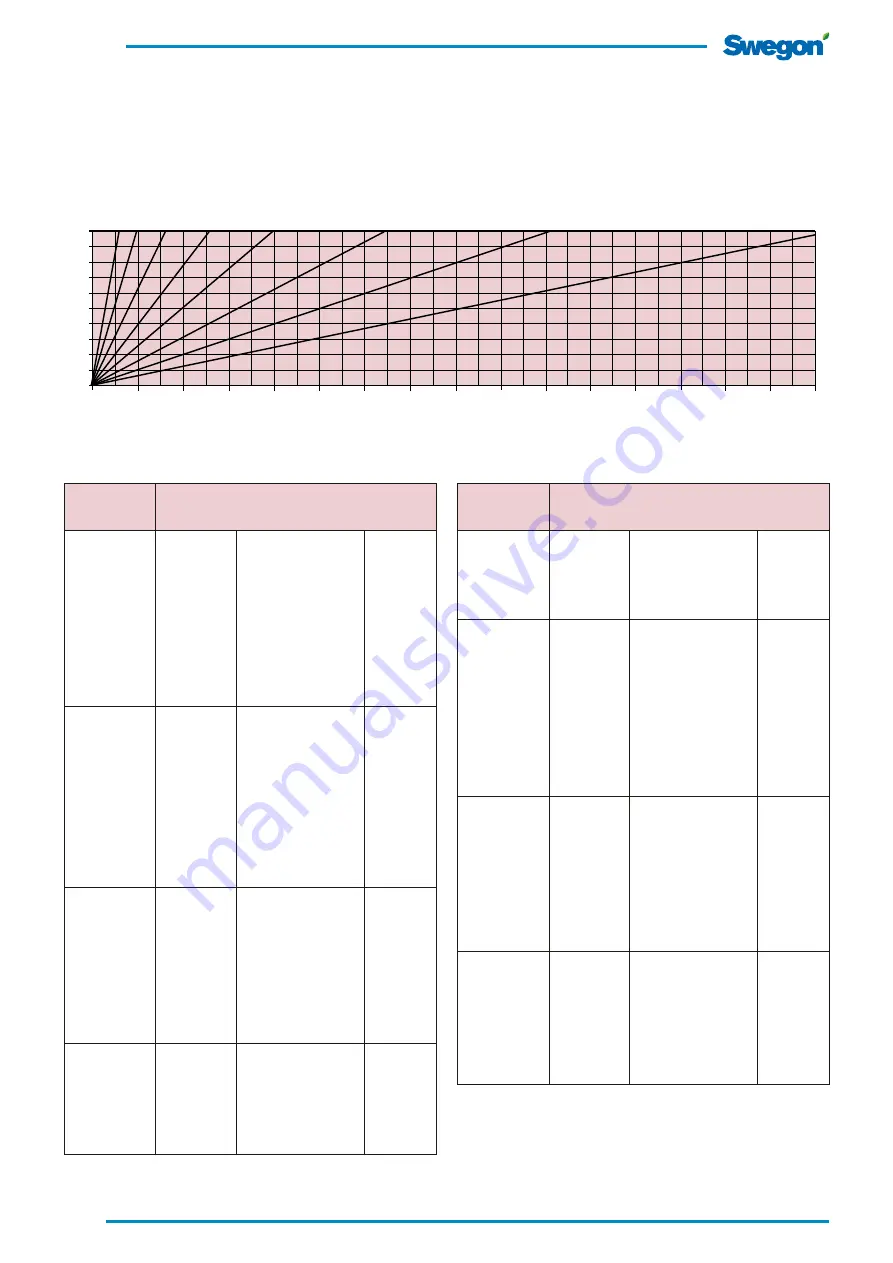

Airflow and K-factor

Size

Airflows (l/s)

Qmin (5Pa)

Qnom/max (120Pa)

K-factor

100

12

58

5.3

125

19

95

8.7

160

35

170

15.5

200

55

272

24.8

250

89

438

40.0

315

142

695

63.4

400

228

1117

102.0

500

367

1797

164.0

200 x 200

75

367

33.5

300 x 200

112

548

50.0

400 x 200

149

728

66.5

500 x 200

187

915

83.5

600 x 200

224

1095

100.0

700 x 200

262

1282

117.0

800 x 200

297

4157

133.0

1000 x 200

373

1829

167.0

300 x 300

170

833

76.0

400 x 300

228

1117

102.0

500 x 300

284

1391

127.0

600 x 300

340

1665

152.0

700 x 300

398

1950

178.0

800 x 300

454

2224

203.0

1000 x 300

568

2782

254.0

400 x 400

304

1490

136.0

500 x 400

382

1873

171.0

600 x 400

458

2246

205.0

700 x 400

534

2618

239.0

800 x 400

610

2991

273.0

Size

Airflows (l/s)

Qmin (5Pa)

Qnom/max (120Pa)

K-factor

1000 x 400

762

3735

341.0

1200 x 400

915

4480

409.0

1400 x 400

1069

5236

478.0

1600 x 400

1221

5981

546.0

500 x 500

479

2344

214.0

600 x 500

575

2815

257.0

700 x 500

671

3286

300.0

800 x 500

767

3757

343.0

1000 x 500

959

4699

429.0

1200 x 500

1149

5631

514.0

1400 x 500

1342

6573

600.0

1600 x 500

1534

7515

686.0

600 x 600

691

3385

309.0

700 x 600

807

3955

361.0

800 x 600

921

4513

412.0

1000 x 600

1152

5642

515.0

1200 x 600

1382

6770

618.0

1400 x 600

1614

7909

722.0

1600 x 600

1845

9037

825.0

700 x 700

944

4623

422.0

800 x 700

1078

5280

482.0

1000 x 700

1348

6606

603.0

1200 x 700

1617

7920

723.0

1400 x 700

1887

9246

844.0

1600 x 700

2156

10560

964.0

1600

1500

1400

1300

1200

1100

1000

900

800

600

700

400

500

200

300

0

100

2

6

4

10

8

U Volt

l/s

Ø500

Ø400

Ø315

Ø250

Ø200

Ø160

Ø125

Ø100

Diagram, true value voltage/airflow

The diagram is applicable only to factory-calibrated

products for nominal airflow according to the Airflow and

K-factor (COP) Table.