W5

Smart

18

All rights to changes reserved.

2020-11-19

Important

The ventilation unit must not be operated

without filters! Use only filters recom-

mended by Swegon in the ventilation unit.

Find the correct filter in the Section enti-

tled: ”Technical data”.

!

!

4.1 Service reminder

The service reminder is activated with preset time inter-

vals and the symbol is displayed on the control panel’s

screen. As a factory setting, the service reminder is not

in operation. It can be put into operation under the

main menu item “Diagnostics”/”Service reminder”. The

recommended service interval for the ventilation unit is

six months.

When servicing has been performed, the service remind-

er is reset from “Alarm” in the main menu.

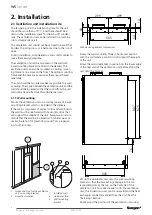

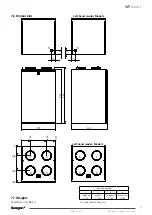

4.2 To open the ventilation unit

Before you begin any service work, isolate the power

supply voltage to the ventilation unit by pulling out its

electric plug from the wall socket. Wait a few minutes

before you open the inspection door of the ventilation

unit so that the fans have time to stop and possible air

heaters have time to cool down.

The inspection door can be opened by turning the lock

bolt with a screw driver for slotted screw heads. Support

the top edge of the door with one hand when you open

the lock bolt. Tilt the top edge outwards, towards you,

and then lift the door away from its place. The door

weighs about 11 kg.

Turn the service switch to the 0-position prior to com-

mencing servicing.

4.3 Filter

The filters should be replaced at least every six months.

The filters may need to be cleaned or replaced more often

in homes where there is considerable dust or if there are

many impurities in the outdoor air.

In a new home, there is still moisture from the construc-

tion period, and the filters can become soiled more quickly

than usual. The first filter change should therefore be

made approximately three months after the ventilation unit

was commissioned.

The ventilation unit must not be operated without filters.

Use only filters recommended by Swegon in the ventila-

tion unit. This is important, as filters with exactly the same

appearance and size can have very different pressure losses

and filter capacity. If an incorrect filter is used, it is not cer-

tain that the ventilation unit will work as designed. Check

in the list of components that you have selected correct

filters.

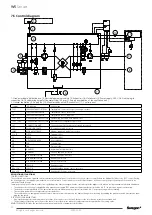

4.4 Heat exchanger

You should check the condition of the heat exchanger

whenever you service the unit.

Pull out the heat exchanger’s sealing plate from the ven-

tilation unit. You can now pull out the heat exchanger

for inspection. Do not damage the heat exchanger fins.

Make sure that the passages through the heat ex-

changer rotor are not clogged and clean them e.g. with

4. Service

running warm water if required. Never use cleaning

agents.

The passages of the heat exchanger should

be dry before you reinstall the heat exchanger in

the unit.

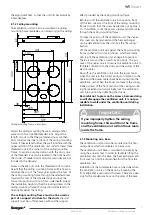

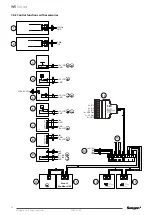

4.5 Fans

The ventilation unit’s fans must be checked at least

every two years.

You must remove the preheater from the ventilation unit

before the supply air fans are loosened. The preheater is

secured in the ventilation unit with three screws.

The fan packages are secured with four screws, placed

in the corners of the mounting plate. When the screws

are loosened, you can pull out the fan package from

the ventilation unit. Exercise care not to damage the fan

cables.

Clean the fans with a soft brush or cloth if necessary. Be

careful not to dislocate the impeller balancing weights.

If significant amounts of dirt collect on the fan impeller

cleaning should be left to a professional.

The fans are reinstalled by sliding them back into place

and tightening the screws in the corners of the mount-

ing plate. The preheater is refitted in position with three

screws.

The ventilation unit’s fans must be loosened

from their locations and protected, for example,

with plastic bags, while the ventilation ducts are

cleaned.

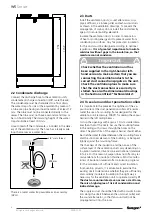

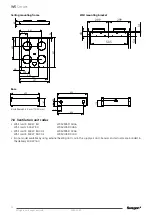

4.6 Other servicing

Clean the inner surfaces of the ventilation unit by

vacuum cleaning or with a damp cloth, if needed.

Check that dirt has not collected on the surfaces of the

air heater/coolers, clean if necessary.

Check that the condensate discharge outlet is not

clogged and check its outflow by pouring water on

the bottom of the ventilation unit. The condensate

discharge connection is located on the rear of the unit

under the rotary heat exchanger.

Check that the ventilation unit works normally and that

no alarms are shown on the screen or on the cooker

hood.