8

W100B.021014

Swegon reserves the right to alter specifications.

www.swegon.com/casa

2.3 Ducts

Install the air ducts, sound attenuators, supply air diffus-

ers, air intake grilles and exhaust air ducts as shown in

the ventilation drawings. To prevent the propagation of

sound, do not install the ducts directly against structural

building elements.

Insulate the air ducts according to the ventilation plan in

order to reduce the losses of heat or cooling and to pre-

vent water from condensing on surfaces. The applicable

fire resistance insulation requirements are also specified

in the ventilation plan.

It is of greatest importance to

insulate cold ducts without gaps in the insulation,

so that moisture cannot condense.

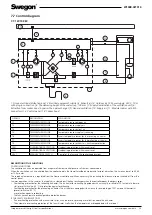

2.4 To connect the cooker hood

The cooker hood is usually connected to the ordinary

extract air duct. However the cooker hood can be

connected to the ventilation unit’s separate extract air

connection, in order to meet national regulations or for

achieving a more effective than normal extract airflow.

The duct between the cooker hood and the ventilation

unit must be installed in such a way that makes it pos-

sible to clean it.

On delivery, the connection for separate extract air is

blanked off.

If you connect the cooker hood to a separate ex-

tract air duct it is important to keep in mind that

the airflow will then bypass the heat exchanger

and this could cause an activation of the anti-

freeze protection function earlier than normal.

Important

The bypass for a kitchen is intended for use

when the airflows from the cooker hood/

kitchen are boosted. The kitchen’s general

ventilation must take place via the extract

air duct. If the general ventilation takes

place continuously via the cooker hood, the

supply air and extract air flows through the

heat exchanger will be out of balance, and

this will lower the efficiency and impair

the ventilation unit’s anti-freeze protection

functions during the winter.

2.5 To seal around duct penetration collars

We recommend the use of a mounting frame designed

for the ventilation unit (accessory) for sealing the vapour

barrier in the loft ceiling beams.

Cut up the openings with approx. 10 mm smaller

diameter than that of the ducts. Secure the mounting

frame in the ceiling with screws through the holes on

the sides. Tighten the plastic of the moisture barrier

between the mounting frame and the structural ele-

ment of the building or fix it in position with tape tightly

against the mounting frame.

It is also important to the preserve the tightness of the

vapour barrier at the duct system’s other penetration

collars that run through the attic joists. A building ele-

ment penetration seal (accessory) will facilitate this. This

item is available in sets of 5 pieces, for diameters: 100,

125 and 160 mm.

The thickness of the insulation and the nature of the

surface layer of the ventilation ducts vary depending on

insulation material, climate zone and national standards

in force. For this reason, Swegon does not offer any

recommendations. Most manufacturers of insulation

material offer calculation programs for the calculation of

sufficient and correct insulation.

In renovation projects, it is advisable to examine the

existing ducts to determine whether they are sufficiently

and correctly insulated. Insulating in the right way is

necessary for the ventilation unit to operate correctly..

If

the ducts are uninsulated, even across a small area,

there is a high degree of risk of condensation and

indirect damage.

The supply air and extract air ducts should be fitted

with acoustic insulation along the stretch between the

ventilation unit’s duct outlet and the sound attenuator,

so that fan sound will not be propagated out into the

room.

In general, ventilation ducts should be insulated in the

following manner:

• Insulate outdoor air ducts run through warm spaces.

• Exhaust air ducts should always be insulated in ac-

cordance with national regulations. See separate

project planning instructions (e.g.e ”Fire resistance

requirements”).

• Insulate supply air ducts in cold spaces.

• Insulate extract air ducts in cold spaces.

• If the air inside the duct is colder than in the sur-

roundings; the insulation should be protected by a

vapour barrier.

Important

Check whether the ventilation unit has

been supplied in the right-hand or left-

hand version to make certain that you are

connecting the air ducts to the correct duct

connection spigots on the unit. Check the

ventilation plans to make sure that the

duct connections are correctly installed.

See also the dimensional drawings in the

Section entitled: “Technical data”.

!

!

!

!