Installation

• There are four hanging eyes for suspended installation.

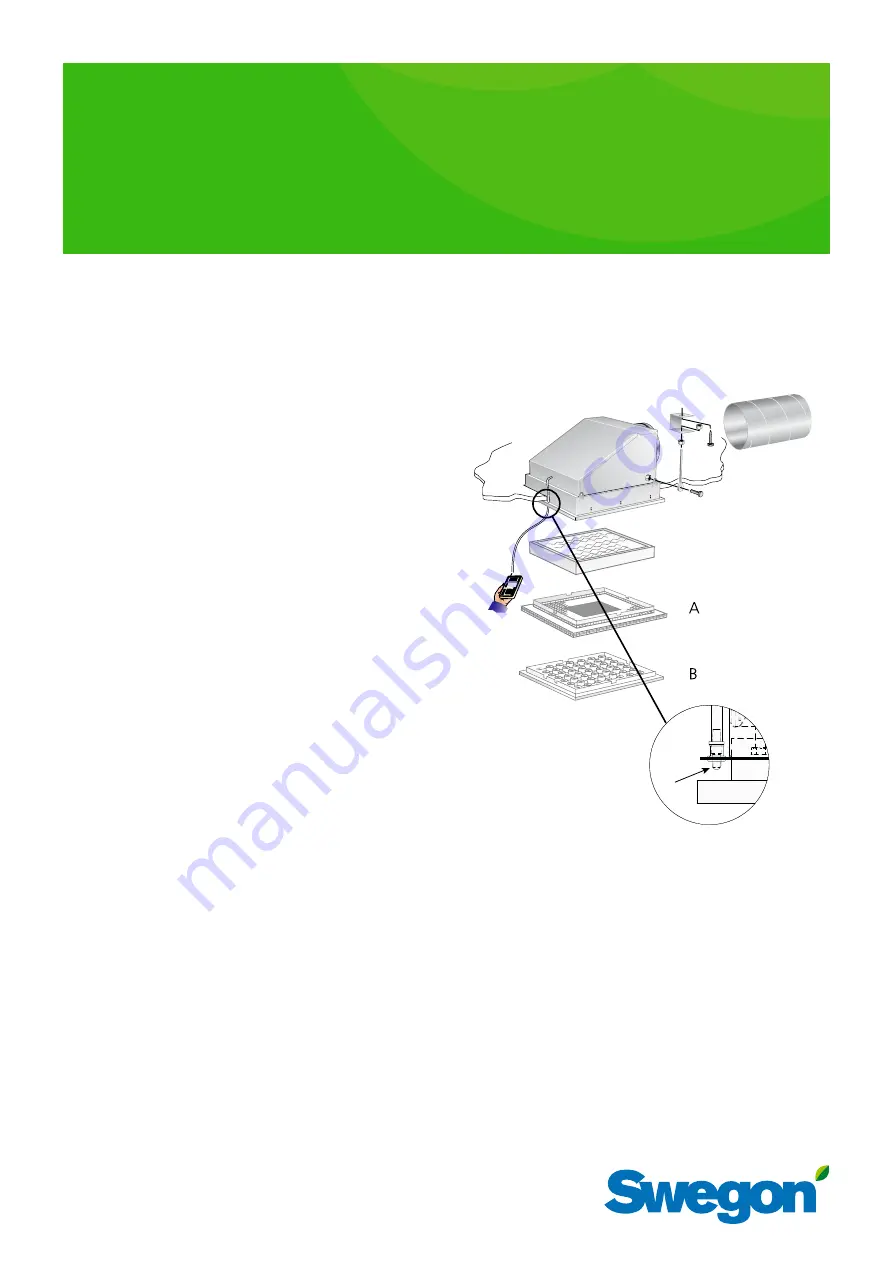

Figure 1, 4 & 6

- Installation fittings/hanger rods are not included.

- It’s important that all four hanger brackets are on the

same horizontal plane (±1.0 mm) to ensure that the filter

fits tightly. See figure 1.

• The rectangular duct connection has a flange design. See

Figure 5.

• The circular connection has a insertion design. See Figure 4.

• Avoid leakage to/from area above the suspended ceiling:

- Seal all joints between the air diffusers and ceiling system

to prevent air in or out from/to the area above the suspen-

ded ceilin

- Duct connections to CDH/CLH must be sealed, check for

leakage.

- Grid system 600x600. Important to mount the diffuser

backing box’s flange under the grid section. Important to

ensure the tightness between the air diffuser and ceiling

system too, see figures on page 2.

Commissioning

The product lacks a commissioning damper. It is recommended

that the ducts before the diffuser are provided with some sort

of commissioning.

Filter

• Recommended final pressure drop depends on the type of

filter and activity.

• Final pressure drop of max 600 Pa or double the initial pres-

sure drop is recommended.

• The pressure drop across the filter is measured in the mea-

surement tapping on the diffuser backing box flange and is

measured in relation to atmospheric pressure, see Figure 1.

• It is necessary to first remove the diffuser plate to access the

measurement tapping.

• There is a test protocol in the filter packaging as well as pro-

duct labels from the filter supplier.

Changing the filter

• Maintenance and care of filters, see page 4.

• Loosen the diffuser plate by carefully pulling it down to

release it from its spring brackets.

• Filter replacement CDH rubber sealed filter:

- Remove 4 M8x40 bolts from the U-beams that hold the

filter against the air diffuser backing box, see figure 2.

Install a new filter as described above but in the reverse

order.

• Use a torque wrench to tighten the bolts with a torque of 4 Nm.

• Filter replacement CLH gel sealed filter:

- Press in the springs that hold the filter in position, see

figure 3. To install a new filter, carefully press the filter into

position until the springs firmly grip the filter.

• NOTE! Max. temperature 70 °C in continuous operation.

Figure 1. Mounting.

A = Perforated diffuser plate.

B = Diffuser plate with nozzles

C = Measurement tapping for DOP test

*)

and pressure

measurement across the filter.

*)

Test of leakage on the product and check of the filter’s particle separa-

tion

efficiency with DOP testing.

C

DOP-testing

For DOP-testing, use the spigot hidden behind the diffusers

front face.

Maintenance

The diffuser should be cleaned when necessary or routinely

using either lukewarm water with detergent added or alcohol.

CDH

b

/CLH

b

Installation – Commissioning – Maintenance

20200626