GB.COMPACTAHSK.210520

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 15

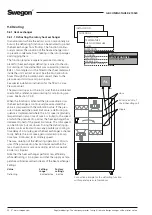

7.3 Switch clock

Basic functions for the switch clock can be preset

at INSTALLATION LEVEL under FUNCTIONS/OPERA-

TION and the values can be read and set at USER

LEVEL.

TIME/DATE

The current date and time can be set and adjusted whenever

required.

The switch clock automatically takes leap years into considera-

tion.

Automatic changeover between summer time/winter time to EU

Standard has been preset.

This changeover function can be blocked at INSTALLATION LEVEL

under FUNCTIONS/OPERATION

.

TIME CHANNEL

Times and days can be set when the unit is to run at high speed,

low speed or be stopped.

Eight different time channels can be set. If the same in-operation

times are to apply every day of the week (Mon-Sun), you need

only program one time channel. Different operation times for

each day of the week can be programmed by programming a

time channel for each day (Mon-Fri, Sat-Sun or Mon, Tues, Wed,

etc)

The time can be set as 00:00-00:00 if the deviating in-operation

period is desirable for the entire 24 hours period.

YEAR CHANNEL

The year channels make it possible to set deviating in-service

times for parts of the day during certain parts of the year. Eight

different year channels (yearly time schedules) can be set. The

year channels over-modulate the time channel during the hours

of the day and the days that the year channel is active. The year

channel dates indicate the dates between which the year chan-

nel shall apply and the year channel hours indicate the hours of

the day between which the year channel will steer the controller

to operate the rotary heat exchanger at a specified speed. Other

times within the year channel still apply to that time channel.

The time can be set as 00:00-00:00 if the deviating in-operation

period is desirable for the entire 24 hours period.

Functions for summer night cooling, prolonged operation, etc.,

operate also when the year channel is active.

7.4 Filters

(and anti-frosting function of rotary heat exchanger)

There are two types of filter monitoring:

Calculated filter monitoring (preset at factory) monitors the fan’s

speed increase conditional on the degree of fouling in the filter.

The calibration involves taking airflow and fan speed readings.

An alarm is initiated when the fan speed has increased by 10%

above the preset alarm limit.

Filter monitoring with a pressure sensor (accessory) measures

the pressure drop across the filter. The alarm limit is preset in Pa.

7.4.1 Readings

When reading the filter status, the first value shows current value

and the second value shows current alarm limit.

7.4.2 To Calibrate the Filters

The filters must be calibrated for the first time during commis-

sioning, when the duct system has been installed and adjusted.

After that every time filters are replaced.

Calibration should be activated for both the supply air and the

extract air if both filters are changed or for only for one airflow

direction if only one filter has been changed.

When filter calibration has been activated, the unit runs at high

speed for about 3 minutes.

After the filter has been calibrated, a speed increase of 10%, or

a pressure rise (= fouling of the filters) of 100 Pa is permissible,

after which an alarm is initiated indicating a fouled filter.

The alarm limit can be changed at INSTALLATION LEVEL under

ALARM SETTINGS.

7.4.3 Calibration - Rotary Heat Exchanger

If the anti-frosting function accessory for heat exchanger is in-

stalled (see 9.6.1.1) calibration can be selected from this menu.

When calibration R-HX is activated the fans are accelerated to

high speed for about 3 minutes.

SWITCH CLOCK

*SWITCH CLOCK*

TIME/DATE

TIME CHANNEL

YEAR CHANNEL

Settings:

Value

Setting

Factory

range setting

TIME/DATE

Day

Mon-Sun

Automatic

Time

00:00-23:59

Current

Date

Day/Month/Year

Current

TIME CHANNEL 1-8

Operation

Low speed/High speed* High speed

Time

00:00-23:59

00:00-00:00

Period

Not active

Not active

Mon, Tues, Wed etc

Mon-Fri

Mon-Sun

Sat-Sun

YEAR CHANNEL 1-8

Operation

Not active

Not active

Stop/Low sp./High sp.

Time

00:00-23:59

00:00-00:00

Period

From Day/Month/Year 01/01/2005

To Day/Month/Year

01/01/2005

*) Shows Stop/Low speed/High speed if this function is selected

at INSTALLATION LEVEL under FUNCTIONS/OPERATION.

FILTERS

*FILTERS*

READINGS

CALIBRATION

*FILTERS*

READINGS

CALIBRATION

*FILTER CALIBRATION*

STD.FILTER

HEAT EXCHANGER