GB.COOLDXS.INS.100507

www.swegon.com

3

We reserve the right to alter specifi cations.

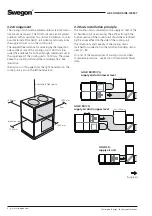

Condenser fans

The cooling unit is equipped with 1-3 condenser fans of

axial type on the hot side. Size 40 capacity variant 2 and

up to size 80 capacity variant 1 have two condenser fans,

size 80 capacity variant 2 has three condenser fans. All

other sizes/capacity variants are equipped with one con-

denser fan.

Condenser fans suck air from the surroundings through

the condenser coils and discharge it upwards.

Condenser fans are equipped with variable speed regula-

tion.

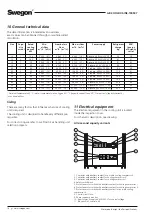

Refrigerant

The cooling unit has one refrigerant circuit. Type R410A

(HFC) refrigerant is used. The refrigerant circuit is charged

with refrigerant on delivery. This type of refrigerant has

no infl uence on the ozone layer.

Refrigerant volume

See section 10 General technical data.

Reporting obligation

The client/user is obligated to fi le a report with the local

inspectorate if the total refrigeration volume is more than

10 kg.

Periodic inspection

If the volumetric weight of the refrigerant in the cooling

unit is more than 3 kg, periodic inspection by an accredit-

ed inspectorate is required. Periodic checks should be car-

ried out every sixth month for the COOL DXS size 60 units,

capacity variants 1 and 2, and for the size 80 units, capac-

ity variant 2. For other sizes and capacity variants periodic

inspection should be carried out every twelve months.

Quality System to ISO 9001

and Environmental Management System to ISO

14001

Swegon AB is involved with a certifi ed quality system that

conforms to ISO 9001 standard and a certifi ed Environ-

mental Management System that conforms to ISO 14001.

1. Overview

1.1. General

COOL DXS is a new cooling unit for comfort cooling, to be

used together with Swegon’s GOLD air handling unit.

The cooling unit is available in 12 capacity variants spread

on nine physical sizes, designed for the size 12 - 80 GOLD

air handling units.

The cooling unit should be placed outside.

The cooling unit should be connected to the supply air

duct behind the GOLD air handling unit.

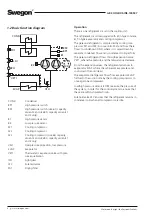

Mechanical design

All the components conform to refrigeration engineering

standards and are pre-wired and collected inside a com-

mon casing.

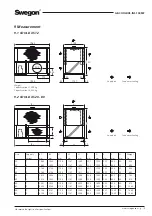

The casing is composed of profi led frame members, cover

panels and inspection covers. The outside is made of

pre-painted (NCS 2005 Y 30R) galvanised sheet steel. The

interior is made of aluminium-zinc treated sheet steel. The

metal thickness is 1.5 mm. In the lower section, the cover

panels and inspection covers are of a sandwich construc-

tion with intervening expanded polyurethane insulation

(35 mm).

The diagonal air cooler is located in the lower section. A

droplet separator with aluminium fi ns is available as ac-

cessory. Double condenser coils are located in the upper

section. The condenser and cooling coils are fabricated of

copper tubing and profi led aluminium fi ns; the casing is

made of galvanized sheet steel.

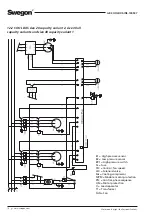

In the upper section, there is an electrical equipment cubi-

cle containing all electrical and control equipment.

All the equipment is easily accessible from the front or rear

for servicing and inspections.

The cooling units are test run prior to delivery.

Cooling compressors

The cooling compressors are located in a separate space in

front of the air cooler (seen from the inspection side). The

sight glass and the expansion valve are also located here,

where they are easily accessible for service.

The cooling compressors are totally hermetical of scroll-

type.

The size 60 COOL DXS in capacity variant 2 and the size

80 in capacity variants 1 and 2 are equipped with three

cooling compressors. All other sizes/capacity variants have

two cooling compressors.

Completely direct-acting system

The cooling unit has a completely direct-acting system. It

has an air cooler for direct-evaporative cooling refrigerant

on the cold side and two condenser coils connected in

parallel on the hot side.