1

DOMO

TM

c

Installation - Commissioning - Maintenance

20150715 / Art. 1545178

Installation

Remove the diffuser face and set the required diffusion pattern.

Note that the transparent air deflector has a slightly wedge-sha-

ped cross section. Install the deflector so that its thinner edge is

positioned towards the bottom of the air diffuser. Press the air

diffuser to secure it to the duct or joint. It will then be held in

place by its built-in spring clips. If required, the air diffuser can

be secured by screws to the duct or to the wall/ceiling. Ultima-

tely, refit the front. See Figures 2 to 5.

NOTE! Never apply any pressure to the diffuser face (cover).

Commissioning

Commissioning must be carried out after the diffuser has been

mounted and completely assembled. Remove the diffuser face

and connect the measurement hose to the measurement tap-

ping and to a manometer. Then refit the diffuser face. The air

flow can be determined using the C-factor of the air diffuser. If

necessary, break off one or more rings from the commissioning

plate to increase the air flow. See table 1. K-factors are specified

on the product’s identification label and in this document.

Maintenance

The air diffuser can be cleaned, if necessary, using lukewarm

water with dishwashing detergent added. The duct system can

be access ed after removing the diffuser face and the commis-

sioning plate.

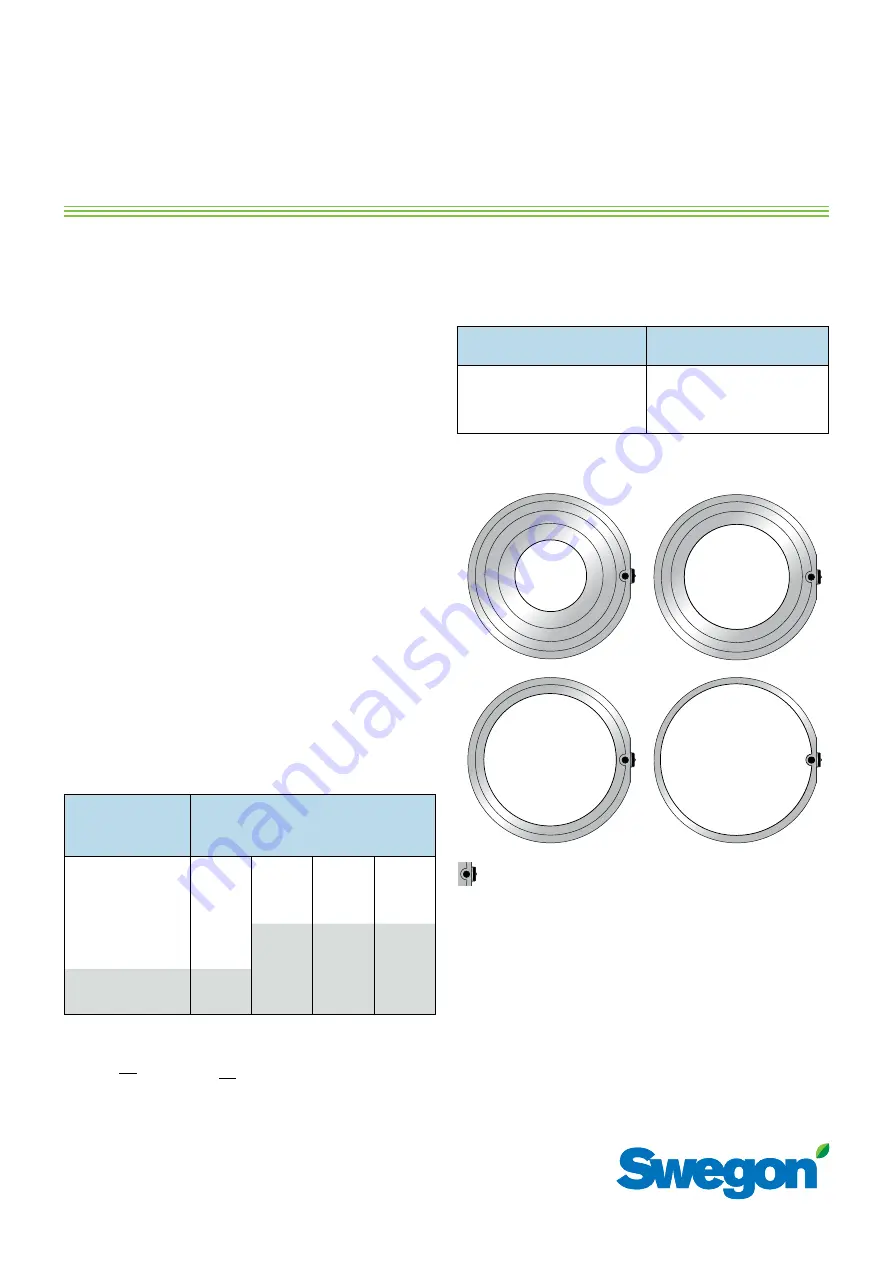

Figure 1. Separable commissioning plate. R1-4 illustrates the dif-

ferent commissioning options with measuring socket positioned

at 3 o’clock.

Calculating airflow using K-factor:

q = k •

√

p

i

[l/s] p

i

=

(

q

)

2

[Pa]

q = flow reading (l/s)

p

i

= current pressure reading (Pa)

k = commissioning factor

k

Table 1 – Commissioning quick guide

White fields indicate sound levels lower than 30 dB(A).

K indicates K-factor (COP).

Pressure in

measuring tube (Pa)

Air flow (l/s)

R1

K = 1,3

R2

K = 2,3

R3

K = 3,3

R4

K = 3,9

10

4

7

10

12

20

6

10

15

17

30

7

13

18

21

40

8

15

21

25

50

9

16

23

25

60

10

18

26

30

70

11

19

28

33

= measuring socket

R1

R2

R3

R4

Table 2 – Duct connection alternatives

Placement of the measuring socket depending on duct connec-

tion alternatives.

Duct connection

Positioning of the

measuring socket

straight connection

3 or 9 o’clock

90° bend, connection up/down

3 or 9 o’clock

90° bend, connection left/right

6 or 12 o’clock