GB.GOLDLP.170830

18 www.swegon.com

We reserve the right to alter specifications without notice.

15

10

20

15

20

25

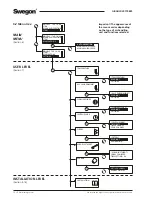

FRT-reglering 1

Extract air temperature °C

Supply air temperature setpoint

°

C

Ste

p 1

Step 2

Breakpoint

EA-/SA dif

ferential

Step 3

Step 4

FRT-reglering 1

9.2.1.1 ERS Regulation

ERS regulation means Extract air temperature-Related

Supply air temperature regulation. This means that the

temperature of the supply air is regulated in relation to the

temperature of the extract air. Under normal circumstanc-

es, the supply air temperature is regulated to be a few de-

grees lower than the extract air temperature. In this way,

the heat exchanger will provide optimal performance, and

this means excellent operating economy. ERS regulation is

suitable for use when there is excess heat in the premises

generated, for example, by machinery, lighting or people

and the supply air devices in the premises are suitable dif-

fusing air below room temperature.

ERS REGULATION 1

The control unit regulates the relationship between the

supply air and extract air temperatures according to a

factory-preset curve.

See the chart to the right.

The steps, breakpoint and EA/SA differential plotted in

the curve can be changed at USER LEVEL under TEMPERA-

TURE/SETTINGS.

Settings:

Value

Setting

Factory

range

setting

Step

1 – 4

1

Breakpoint

15-23 °C

20 °C

(refers to extract air temp.)

EA/SA-Differential

1-5 °C

2 °C

The setting range for the breakpoint and EA/SA differen-

tial is limited by the Min. and Max. settings at

INSTALLA-

TION LEVEL under HAND TERMINAL.

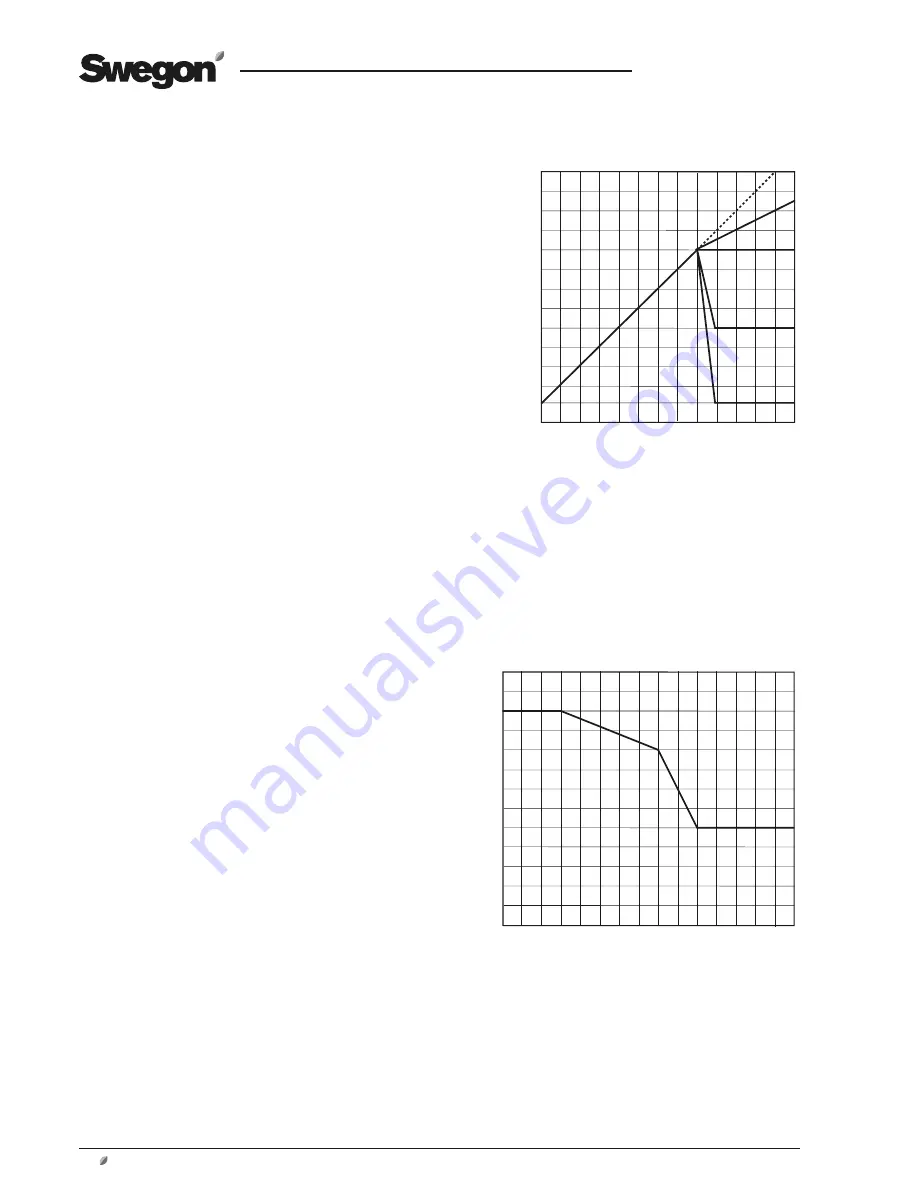

ERS REGULATION 2

This is used when special needs and conditions are such

that the factory preset ERS regulation 1 curve cannot pro-

vide the results required. Conditional on which settings are

made, it may be necessary to install a post-heating coil.

An individually adapted curve regulates the relationship

between the supply air and extract air temperature.

See the chart to the right.

The following settings are possible at USER LEVEL under

TEMPERATURE/SETTINGS:

Value

Setting

Factory

range setting

Extract air temperature

X1 10-38 °C 15 °C

X2 11-39 °C 20 °C

X3 12-40 °C 22 °C

Supply air temperature setpoint

Y1 10-40 °C 20 °C

Y2 10-40 °C 18 °C

Y3 10-40 °C 14 °C

The setpoint displacement and summer night cooling

functions can also affect the preset temperatures.

Breakpoints according to factory setting means:

If the extract air temperature is below 15 °C (X1) the set-

point for supply air temperature is constant 20 °C (Y1).

If the extract air temperature is 20 °C (X2) the supply air

temperature set point will be 18 °C (Y2).

If the extract air temperature is above 22 °C (X3), the

supply air temperature setpoint will be constantly 14 °C

(Y3).

Factory setting means:

If the extract air temperature is below 20 °C (breakpoint),

the supply air temperature setpoint will be automatically

regulated to be 2 °C (EA/SA differential) lower.

If the extract air temperature is above 20 °C, the supply

air temperature setpoint will follow the curve according to

Step 1.

1

2

3

15

20

22

9

10

12

15

20

25

27

X = Extract air temperature °C

Y = Setpoint supply air temperature °C

ERS regulation 2