Accessories

Commissioning box:

ALS. The ALS commissioning box is made of galvanized sheet steel

and contains a removable commissioning damper, fixed measurement

tapping and sound absorbing material*

)

with reinforced surface layer.

The ALS commissioning box is available with one or two differences in

dimension between the inlet and the outlet and also a version for low

installation where a low overall height is required. The ALS commission-

ing box is then supplied without outlet branch.

*

)

Fire resistance rated to B-s1,d0 in accordance with EN ISO 11925-2.

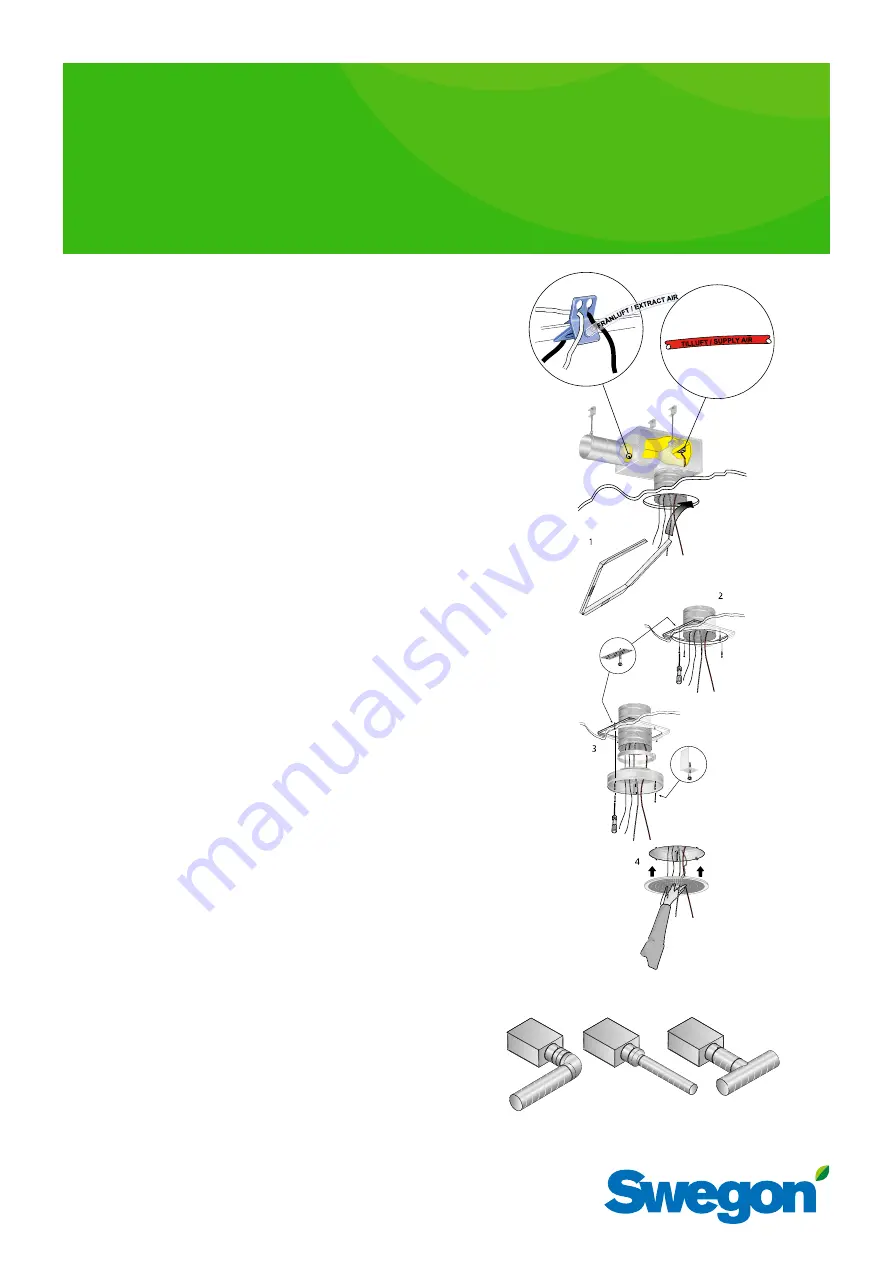

Installation

Cut the opening in the false ceiling according to the dimension print

and the table with measurements. Place a mounting frame on top of

the false ceiling and unfold it to form a square frame around the open-

ing. Secure the frame with screws from the underside. Tighten the

screws through the false ceiling slab, into the perforation on the long

sides of the frame. If a flexible tube is used as the connecting duct,

connect it at this phase of the work, and fasten it to the air diffuser

with a hose clamp. Place the diffuser backing box in the opening with

four angle brackets firmly against the false ceiling. Tighten the screws

through the angle brackets and into the false ceiling slab and into the

perforation of the mounting frame. Fasten the diffuser face in the

safety chain and press it into its spring mounts.

If an ALS commissioning box is used, the sleeve coupling between the

ALS and the air diffuser can be lengthened using an ordinary circular

duct of up to 500 mm without having to lengthen the measuring

tubes and damper adjustment cords. See Figure 1.

Commissioning

Commissioning should be carried out with the diffuser face mounted.

Pull out the measuring tubes and damper adjustment cords through

the diffuser face perforations. Connect a manometer to the measuring

tube. The desired commissioning pressure can be computed by apply-

ing the rated coefficient of performance of the air diffuser. Set the

damper to the correct blade position, tie a commissioning knot in the

damper cords to indicate the damper position.

Measurement accuracy and requirement on straight duct before the

commisioning box, see Figure 1. The requirements of straigh duct

depends on the type of disturbance before the commissioning box.

Figure 1 shows a bend, a dimensional change and a T-piece. Other

types of disturbances requires at least 2xD straight (D = connection

dimension) for measurement accuracy of ± 10% of the flow.

The K-factor (COP) is specified on the product’s identification label.

K-factors can also be found in the relevant commissioning instructions

at www.swegon.com.

Maintenance

The air diffuser can be cleaned, if necessary, using lukewarm water

with dishwashing detergent added. The duct system can be reached

by dismantling the diffuser face. Pull the distributor plate in the ALS

commissioning box aside and then twist the damper unit from of its

mounting. See Figure 1.

Figure 1. Installation. Commissioning.

0xD / ±5%

0xD / ±5%

2xD / ±10%

LPA

a

Installation – Commissioning – Maintenance

20150101