34

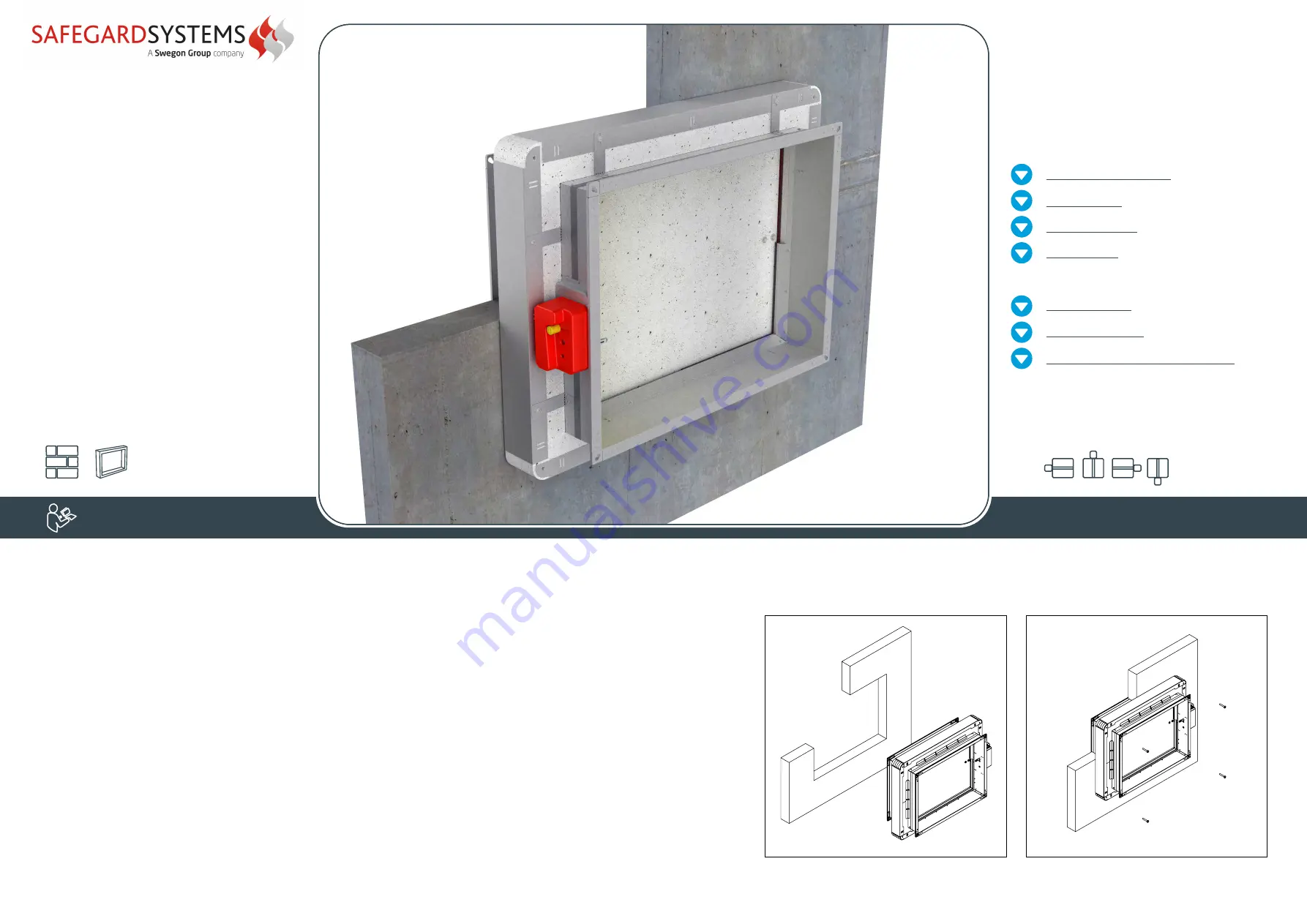

FIRE DAMPER - FD

Possible damper orientations

Rigid wall

installation

MF1/MF2

installation frame

The wall is composed of concrete blocks

(minimum density of 550 kg/m³) or

reinforced concrete (minimum density of 2200 kg/m³)

and with a minimum thickness of 100 mm.

1. Recommended wall opening for the fire

damper installation is B (H) + 80 mm.

Damper blade must be closed during

installation!

2. Insert fire damper into wall and fasten

with screws.

FD25 - 4 pcs, 6x140 mm,

FD40 - 12 pcs, 6x140 mm

Test the operation of the damper blade!

2

1

INSTALLATION

Always e

nsure the damper is sufficiently supported