42

FIRE DAMPER - FD

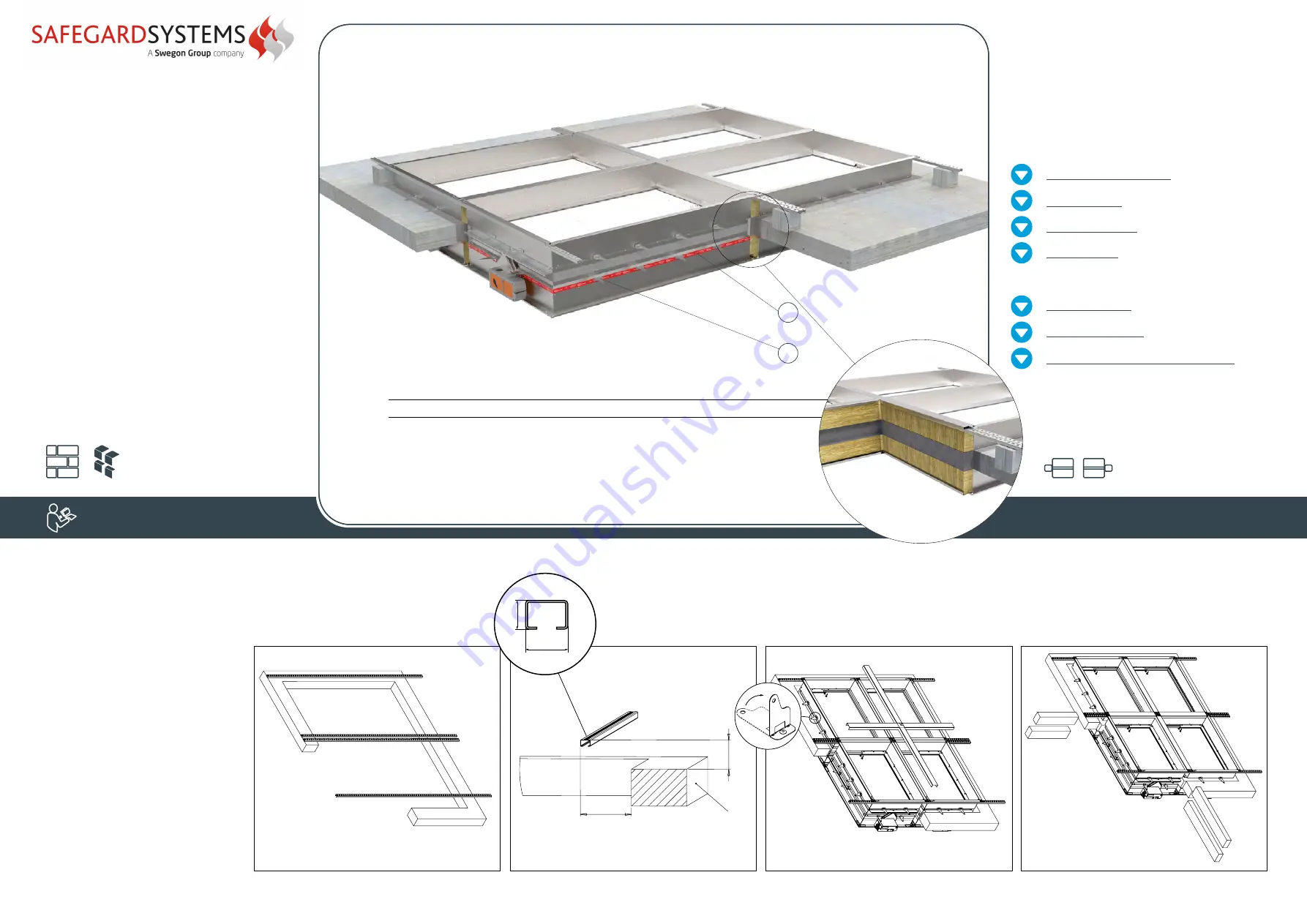

Possible damper orientations

Battery assembly

installation

(floor/ceiling)

2x2

The floor/ceiling is composed of concrete blocks

(minimum density of 550 kg/m³) or reinforced

concrete (minimum density of 2200 kg/m³) and with

a minimum thickness of 100 mm.

118

42

wall

118

42

wall

118

42

wall

2

1

4

3

Maximum dimension of fire dampers:

2X2 grid: 1500x800 mm

*For battery installation 2x2 use 8x connecting

frame and 2x connecting plate.

Installation only possible with FD40!

(1)

Accessories

(2)

Type

(3)

Length

FD-A

-

CF60

- 800

(1)

(2)

Fire damper accessories

FD-A

Type

CF60

- Connecting frame 60 mm

CF100

- Connecting frame 100 mm

CP60

- Connecting plate 60 mm

CP100

- Connecting plate 100 mm

(3)

Connecting frame length

200 ... 1500 [mm]

floor/ceiling

18mm

27mm

INSTALLATION

B

A

1.

Prepare a hole of dimensions

2B + Connecting frame width (CF60/

CF100) + 80 mm and 2H + Connecting

frame width (CF60/CF100) + 80 mm.

Set

all U profiles to a height of 118 mm

(use blocks of aerated concrete to keep

distance between ceiling and profiles).

2.

Arrangement of steel C profiles

(27x18 mm).

3.

Place the dampers in the openings to

the wall limit mark

(A)

and bend the fixing

bracket

(B)

90°. Put them on U profiles.

Fix the dampers and profiles to the ceiling

using the screws for concrete. Place four

connection profiles from the installation kit

to the dampers on both sides and attach

it using the self-tapping screws.

4.

The space between fire dampers

and

floor

and fire dampers themselves

should be filled with mortar/gypsum in

the

thickness of the concrete slab. The

remaining free space between damper

casings (above and below mortar filling) should

be filled with mineral wool (density 100kg/m³ or

higher). The recommended procedure is to install

the lower mineral wool between casings and use

it as formwork. Install additional wooden formwork

around the perimiter of the installation between casing and concrete slab.

Pour in the mortar up to the thickness of the concrete slab.

When the mortar sets, fill the upper space between casings with the mineral wool.

Damper blade must be closed during installation!

Test the operation of the damper blade!

pod/strop

Always e

nsure the damper is sufficiently supported