GB.TBXZ342.130915

Registered design. The company reserves the right to make changes without prior notice.

10 www.swegon.com

Important!

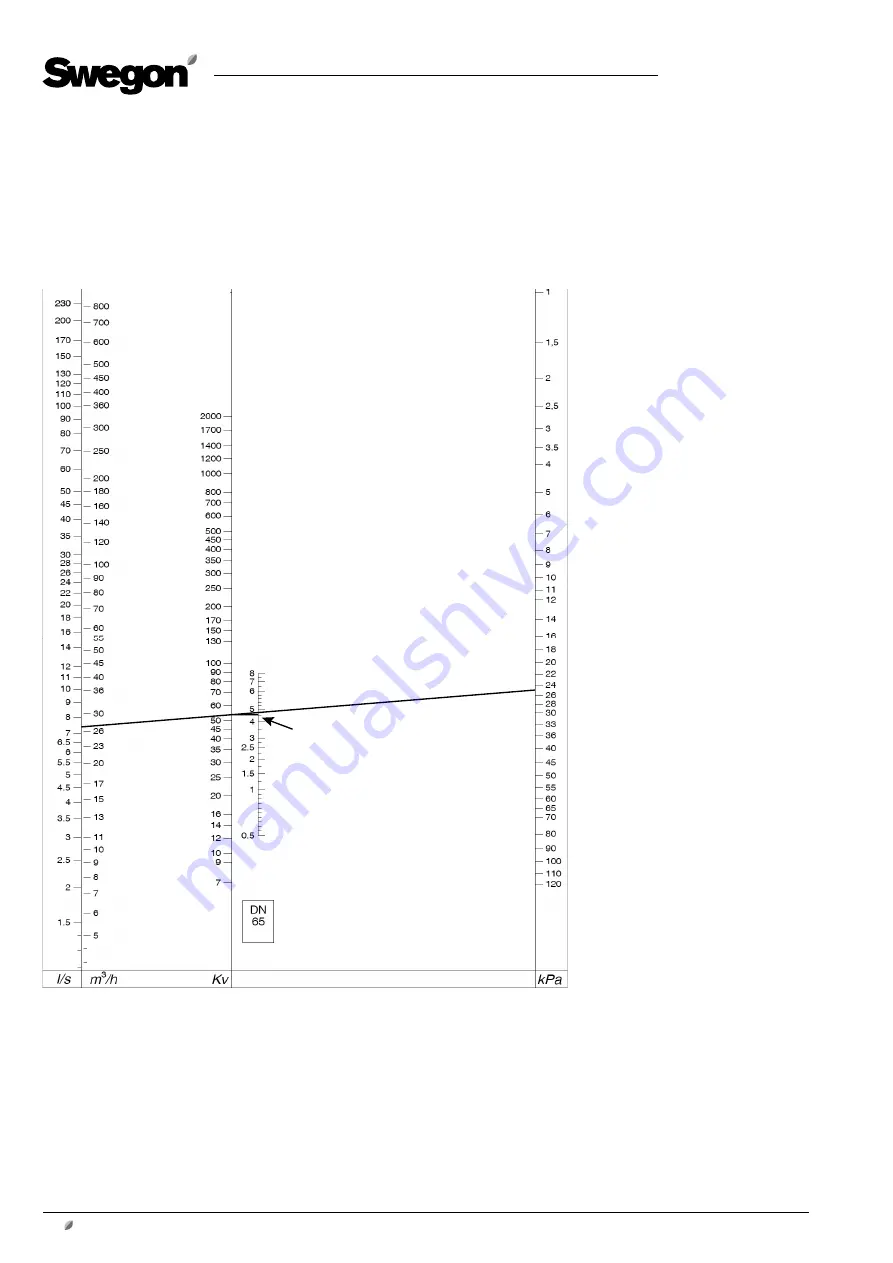

If the flow is outside the chart, it can be read as follows:

Assume the example above that reads 25 kPa, Kv=53 and

a flow of 27 m

3

/h. For 25 kPa and Kv=5,3 you read a flow

of 2,7 m

3

/h and for Kv=53 you read 270 m

3

/h. Therefore,

for every given pressure drop you can read 0.1 or 10 times

the flow and Kv.

Example

This chart shows the pressure drop across the valve. A

straight line that interconnects the scales for flow – Kv

- pressure drop constitute the relationship between the

different readings.

The position for each valve size can be obtained by plot-

ting a horizontal line from the value intersected on the Kv

scale.

Sought

Presetting for DN 65 and required 27 m flow

3

/h and pres-

sure drop of 25 kPa.

Solution

Plot a line between 27 m

3

/h and 25 kPa. This intersects the

Kv scale at KV=53. Then plot a horizontal line from Kv 53

to the DN 65 scale where you read 4,5 turns.

7.2 DN 65 (GOLD SD 100/120, GOLD CX 100/120)