SWEISS

WELD.COM

info@sweissweld.com

OPERATION

15

§4.3

Welding Operation

§4.3.1

Argon Arc Welding Operation

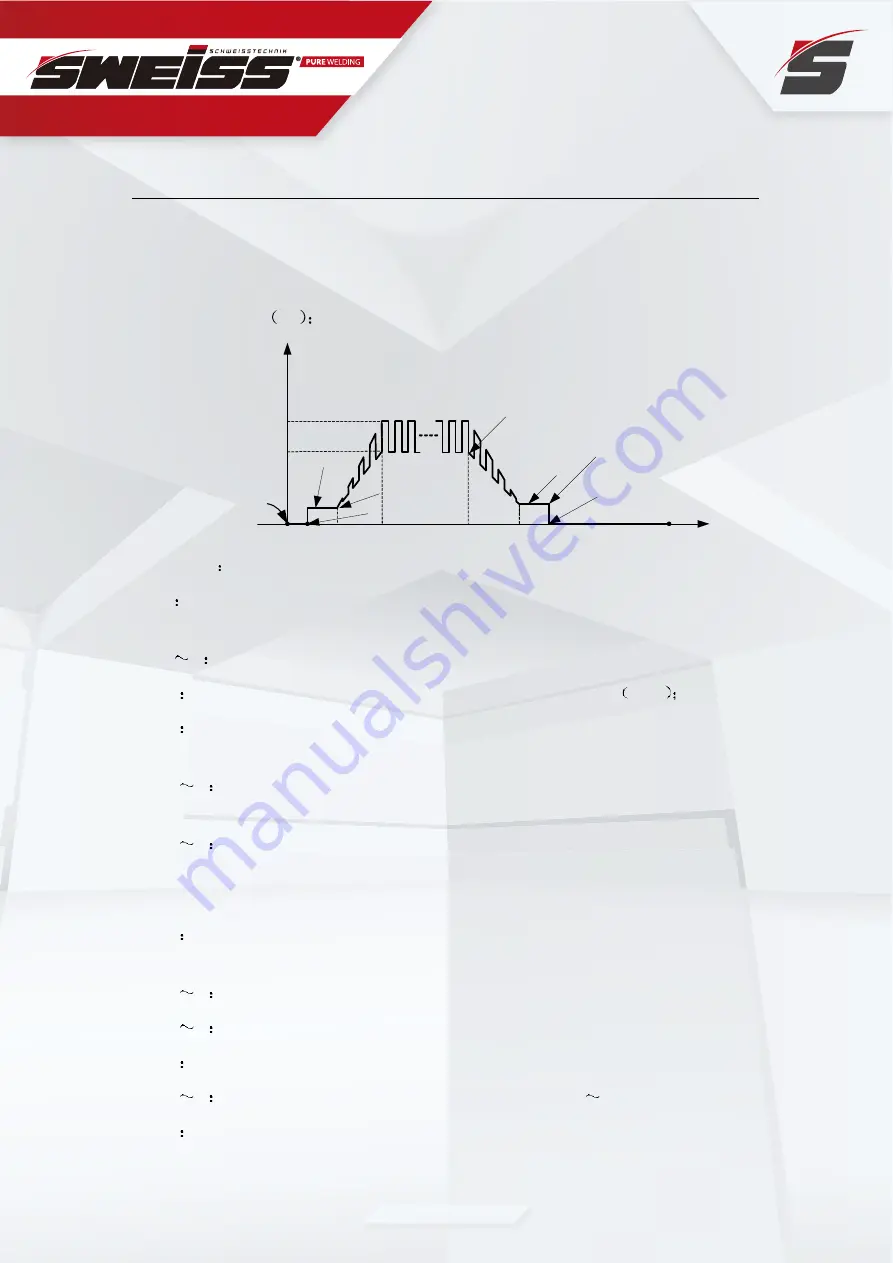

TIG long welding 4T

Introduction

0

Press and hold the gun switch, Electromagnetic gas valve is turned on. The

shielding gas starts to flow;

0 t1 Pre flow time, adjustment range of pre flow time :0~1.0S;

t1 Striking success, adjustment range of start current: 5~160A 200A

t2

Loosen the gun switch, the output current slopes up from start current; if the

output pulse function is turned on, the output current is pulsed;

t2 t3 Output current slopes up to the setting current value; adjustment range of up

slope time 0~5.0S ;

t3 t4 Welding process. During this period, the gun switch is loosen;

Note: If the output pulse function is turned on, the output current is pulsed. If the output

pulse function is turned off, the output current is DC current;

t4 Repress down the gun switch, the output current slopes down to crater current; if

the output pulse function is turned on, the slope down current is pulsed;

t4 t5 Down slope time, adjustment rang of down slope time: 0~5.0S;

t5 t6 Crater current holds time; adjustment range of crater current: 5~160A (200A);

t6 Loosen the gun switch, stop arc, and keep on argon flowing;

t6 t7 Post flow time, adjustment range of post flow time: 3.0 10.0S;

t7 Electromagnetic valve is closed and stop argon flowing. Welding is finished.