SWEISS

WELD.COM

info@sweissweld.com

INSTALLATION AND ADJUSTMENT

Note: T

he above parameters are subject to change with the improvement of machines.

§3.2 Duty cycle & Over heat

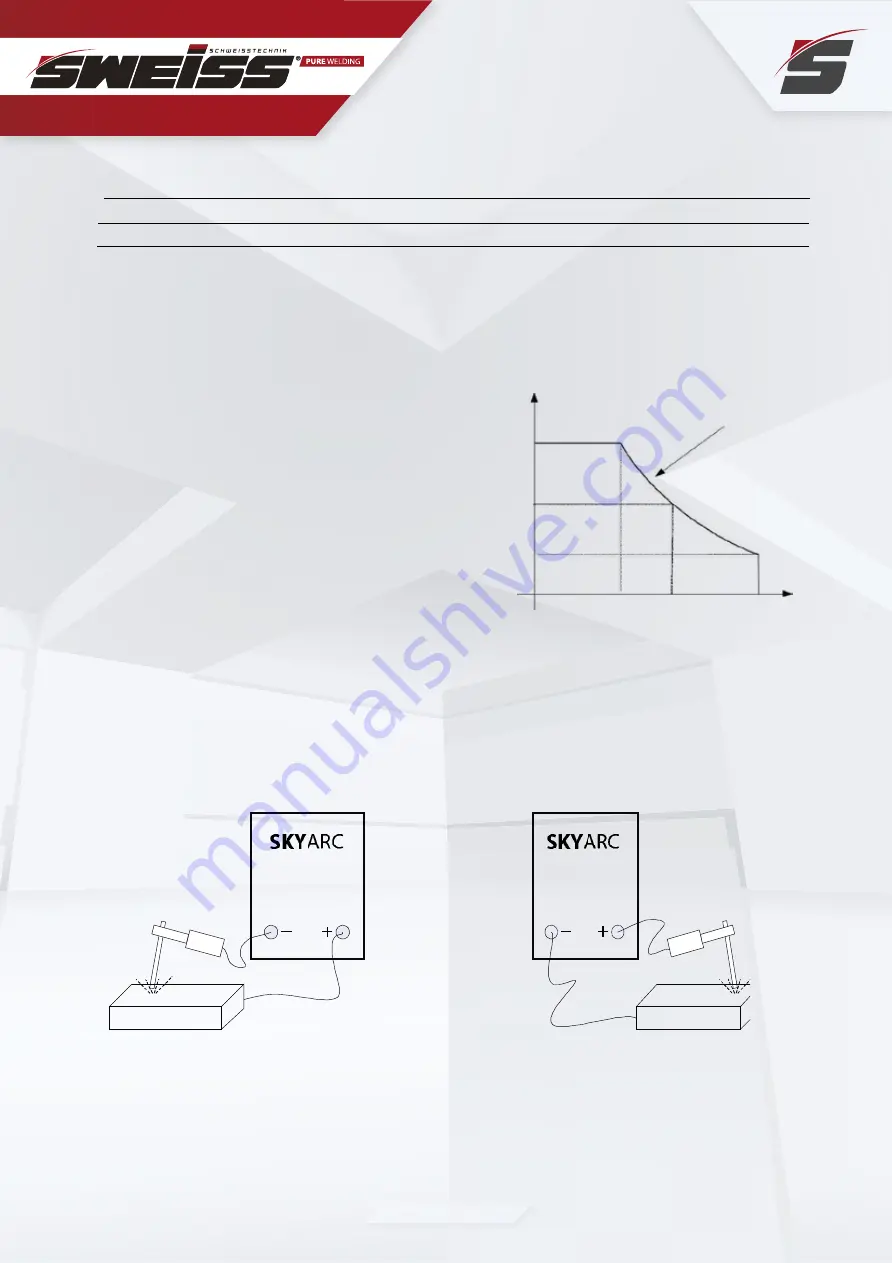

The letter “X” stands for duty cycle, which is defined as the proportion of the time that a

machine can work continuously within a certain time (10 minutes). The rated duty cycle

means the proportion of the time that a machine

X

can work continuously within 10 minutes when it

100

outputs the rated welding current.

The relation between the duty cycle “X” and

the output welding current “I” is shown as the

right figure.

If the welder is over-heat, the IGBT over-heat

protection unit inside it will output an instruction

to cut output welding current, and brighten

the over-heat pilot lamp on the front panel. At this time, the machine should be relaxed

for 15 minutes to cool the fan. When

operating the machine again, the welding output current or the duty cycle should be

reduced.

workpiece

Welding holder

electrode

DCEP

workpiece

electrode

DCEN

Welding holder

Choosing the connection of DCEN or DCEP is based on the arc stable burning condition. The

different electrodes need different connection way. Please refer to the electrode manual.

8

§3.3 Welding polarity connection way

§3.3.1 MMA (take SKYARC one FX for an example)

The relation between duty cycle and

welding current for ONE/2050