8.

positive output cable

connected to the work piece

9.

power cable

connected to the appreciate power supply

10.

power switch

turn on or off the power source

11.

compressed air connector (Note:

air pressure has to be set inside. That is 4bar/60psi)

5

4.2 Cutting Preparation

1

、

Tightly connect the power cable to electrical socket outlet (the input voltage, refer to the section 2 technology

parameters)

2

、

connect the air pipe to the air supply equipment, the earth cable to the workpiece

3

、

turn on the power switch ,the power source lamp on.

4

、

turn the RUN/SET switch to SET position, gas test.

5

、

turn the RUN/SET switch to RUN position, regulate the current after the flow stops.

6

、

now all the preparation done .

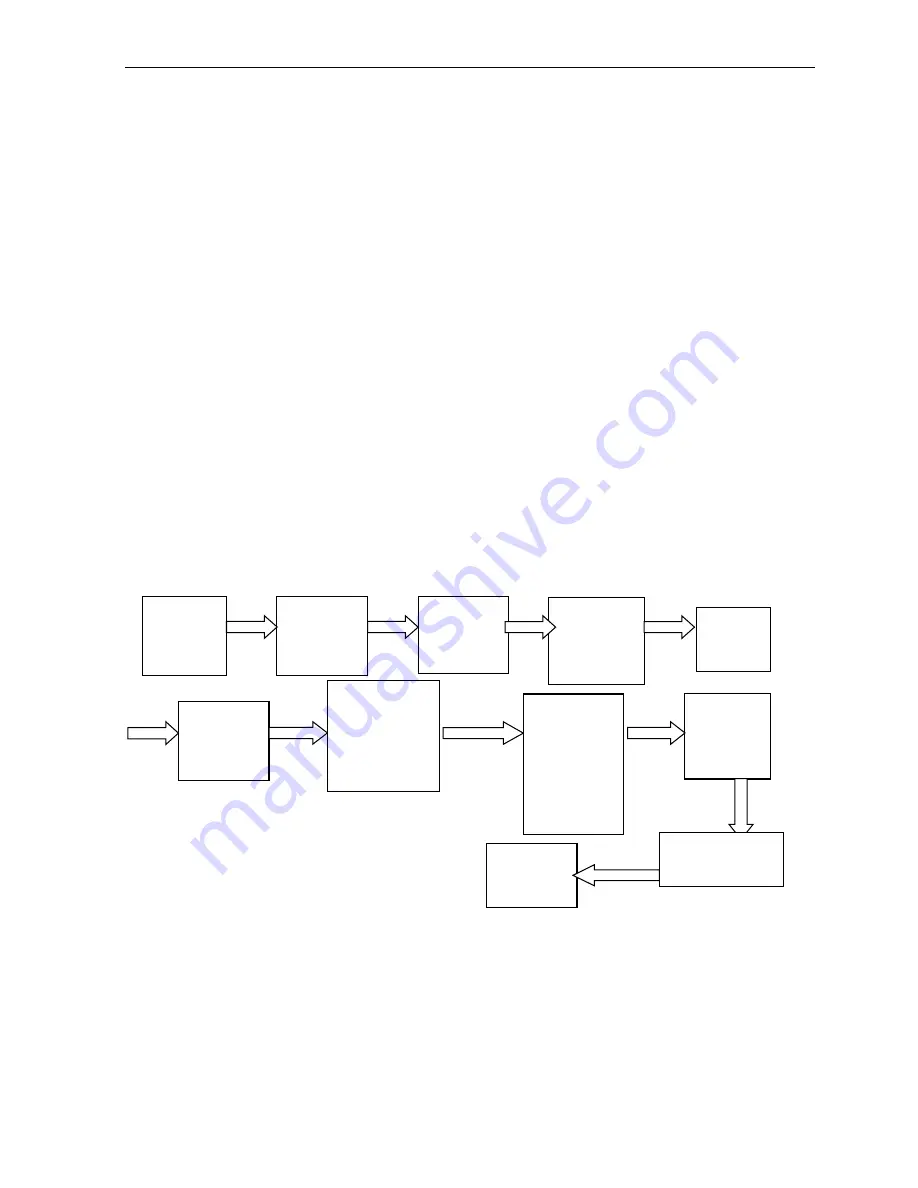

4.3 Cutting Operation

Note

:(

1

)

The alarm lamp on when cutting, it is needed to loose the switch of the torch until the alarm release,

then press on the switch to start cutting again.

(

2

)

In the automatic gas test and examine, press on the cutting torch, there will no reflection.

(

3

)

After a long usage, the surface of the electrode and nozzle will have Oxidation reaction. Please replace

Turn

on

the power

source

Automatic

gas test for

10S

Loose the

cutting

torch

switch

Pre-gas

for 2s

the torch

leaves the

work piece,

the cutting

arc change

into pilot arc

again

automatic

examine for

5s

press on the

cutting

switch

Ignite

the

pilot arc

Post-gas for

20s

shift to the

work piece, the

pilot arc

change into

cutting arc

Arc

extinguished

Summary of Contents for SKYCUT 440

Page 15: ...NOTES...