SWEISS

WELD.COM

info@sweissweld.com

INSTALLATION AND ADJUSTMENT

11

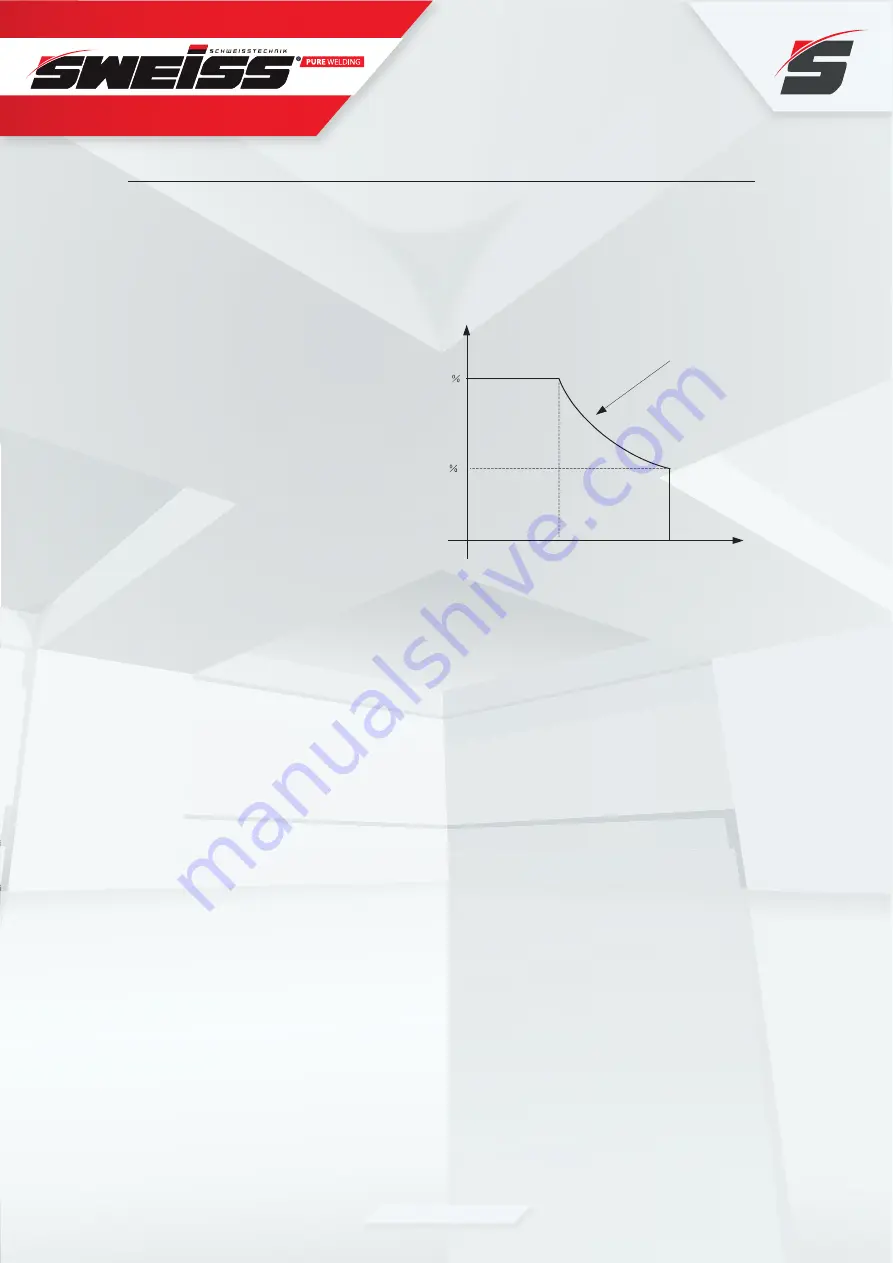

§3.2 Duty cycle & Over heat

The letter “X” stands for duty cycle, which is defined as the proportion of the time that a

machine can work continuously within a certain time (10 minutes). The rated duty cycle means

the proportion of the time that a machine can work continuously within 10 minutes when it

outputs the rated welding current.

The relation between the duty cycle

“X” and the output welding current “I” is

shown as the right figure.

If the welder is over-heat, the IGBT over-

heat protection unit inside it will output an

instruction to cut output welding current,

and brighten the over-heat pilot lamp on the front panel. At this time, the machine should be

relaxed for 15 minutes to cool the fan. When operating the machine again, the welding output

current or the duty cycle should be reduced.

§3.3 Movement and placement

Please take care for the welder when moving it, and do not make it sloped.

It also can be moved by the handle on the top of the welder. Place the welder well when

moving it to the right position. When the machine gets to the destination, it needs to be fixed

up to avoid gliding.

When using forklift, its arm length must be long enough to reach the outside so as to ensure

lifting safely.

The movement may result in the potential danger or substantive hazard, so please make

sure that the machine is on the safe position before using it.

§3.4 Power supply input connection

SKYTIG 2045 ACDC welding machines’ power supply connects to 220V.

I

(

A

)

0

100

25

100

200

X

The relation of the welding current and

duty cycle for WSME-200