MONTAGE

Les tuyaux doivent être raccordés de manière à ce que la dilatation thermique

n’affecte pas l’échangeur de chaleur au niveau des raccords. S’il existe un risque

que la pression statique puisse dépasser la pression nominale, une soupape de

sûreté doit être installée. Ne jamais exposer l’unité à des pulsations ou des

variations cycliques excessives de la pression ou de la température. Il est

également essentiel qu’aucune vibration ne soit transmise à l’échangeur de

chaleur. Si un tel risque subsiste, installez des amortisseurs de vibrations.

Utilisez une bande de montage en caoutchouc en guise d’amortisseur entre le

Minex et la bride de fixation. Le sens de pose influe peu ou pas du tout sur le

rendement du Minex.

Plusieurs solutions de montage du Minex SWEP sont illustrées ci-dessous.

a)

b)

c)

d)

a) Supporté par la base

b) Tôle métallique de support (joint en caoutchouc entre la bride et l’échangeur)

c) Barre transversale et boulons (joint en caoutchouc entre la barre

transversale et l’échangeur)

d) Pour un Minex plus petit, il est également possible de poser l’unité en la

suspendant simplement aux conduites/raccords.

RACCORDS

Suivant les normes nationales/locales et l’application, il existe différentes options

de raccordement. Il est important de disposer de raccords conformes à la norme

internationale ou nationale, étant donné qu’ils ne sont pas toujours compatibles.

La conception des raccords de Minex diffère quelque peu de celle des raccords

de CBE.

Raccords à enclenchement

La plaque de bâti du Minex dispose de fentes

spécialement conçues dans lesquelles les raccords

peuvent être insérés. Lorsque le paquet de plaques est

assemblé, les raccords sont verrouillés en position.

Le verrouillage des raccords au bâti s’effectue sans

soudure ni brasure des connexions. Cela signifie par la

même occasion que le matériau des raccords et des

bâtis peut être personnalisé suivant les préférences et

les exigences du client, par ex. un bâti en acier au

carbone anticorrosion combiné à des raccords en acier

inoxydable peu coûteux d’un côté et des raccords en

titane de l’autre.

Tous les raccords sont dotés d’un bouchon en plastique

spécial destiné à protéger le raccord fileté et empêcher

la pénétration de saleté dans le Minex. Ce bouchon en

plastique doit être enlevé avec précaution, pour éviter

d’endommager le filet, la surface d’étanchéité ou tout

autre élément du raccord. Utilisez un tournevis, une

pince ou un couteau.

Surface d’étanchéité

Raccords filetés

Exemples de raccords filetés: raccord fileté femelle/mâle, ISO-G, NPT, ISO 7/1

Raccords filetés à

l’extérieur (Mâles)

Raccords filetés à

l’intérieur (Femelle) ou

de type standard

Raccords filetés à

l’intérieur (Femelle)

avec

un extérieur

hexagonal

STRAINERS

If any of the media contain particles larger than 1 mm (0.04 inch), we recommend

installing a strainer with a size of 16-20 mesh (number of openings per inch)

before the exchanger. The particles could otherwise block the channels, causing

bad performance, increased pressure drop and risk of corrosion. Some strainers

can be ordered as accessories.

INSTALLATION OF MINEX IN SINGLE-PHASE

APPLICATIONS

Normally, the circuit with the highest temperature and/or

pressure should be connected on the left side of the heat

exchanger when the arrow points upwards. For example,

in a typical water-to-water application, the two fluids are

connected in a counter-current flow, i.e. F1 for the hot

water inlet, F3 for the outlet, F4 for the cold-water inlet and

F2 for the outlet. This is because the right-hand side of the

heat exchanger contains one channel more than the left-

hand side, and the hot medium is thus surrounded by the

cold medium to prevent heat loss.

F1

F2

F3

F4

Start-up

Make sure that the tightening measure (total plate package measurement) is

correct according to the label on the heat exchanger. Close the pump discharge

valves to the heat exchanger completely. The static pressure must be increased

slowly until the operating pressure is reached, in order to not displace the

gaskets. It is recommended that the inlet valves on both sides are opened

simultaneously to avoid over-pressure on one side. It is also important to avoid

hammering, as the elastomer gaskets may be displaced and thereby cause

leakage.

Dismantling

The pressure on both sides should be decreased simultaneously and gradually

when shutting down the unit. Remove the pipe work connected to the heat

exchanger. The tightening bolts must be loosened with the frame and pressure

plate as parallel as possible. This is most easily done with a hydraulic hand pump.

For M10:

Start to release the center nut and unscrew the bolt from the unit. NOTE! Do not

punch the bolts through the plate package as this might damage the channel

plates. Loosen the upper and lower tightening bolts max 2-3 mm (0.1 inch) at a

time, in order to keep the plate package parallel.

Since the gaskets are not glued, try to keep the plate package together. Keep the

unit lying on the back, P-side, and remove one plate at the time. The start gaskets

are made of two half-channel plate gaskets and should be removed carefully and

saved. On the M10 you also have a center ring gasket on each plate, which seals

off the center-tightening bolthole. There is only one way to place the gasket in the

groove. The start plate gaskets therefore have to be adjusted (with a pair of

scissors) to fit in to the gasket groove.

Start plate (4-hole)

with gasket

Channel plate (4-hole)

with gasket

End plate (0-hole)

without gaskets

Assembly of plates

The plates should always be mounted with the gasket facing the front frame

plate. Make sure the center ring gaskets are correctly located in the gasket

groove in the middle of channel plate. In a single-pass unit, the start plate should

always be mounted with the herringbone pattern pointing down, in the opposite

direction of the arrow on the front of the frame. Make sure to alternate the channel

plates so that every second plate has the arrow pointing up and on every second

pointing down all through the plate package.

The bolts are short in order to decrease the outline dimensions. To be able to

mount the nut on the bolt, we recommend using a screw clamp or similar tool to

tighten the unit enough

.

After this tightening, the upper and lower bolt can easily

be located in their holes. Take care that the plate package is not over-tightened as

this might cause deformation of the plates and gaskets and thus affect the

thermal performance. After dismantling and cleaning, always let the gaskets dry

for 24 hours so they can revert to their original form before assembly. This

procedure will prevent the risk of leakage and should not be ignored. The

performance of the heat exchanger and the lifetime of the gaskets depend on the

accuracy of the tightening. If leakage occurs when the plate pack is equal to the

total plate package measurement, the gaskets should be replaced instead of

further tightening.

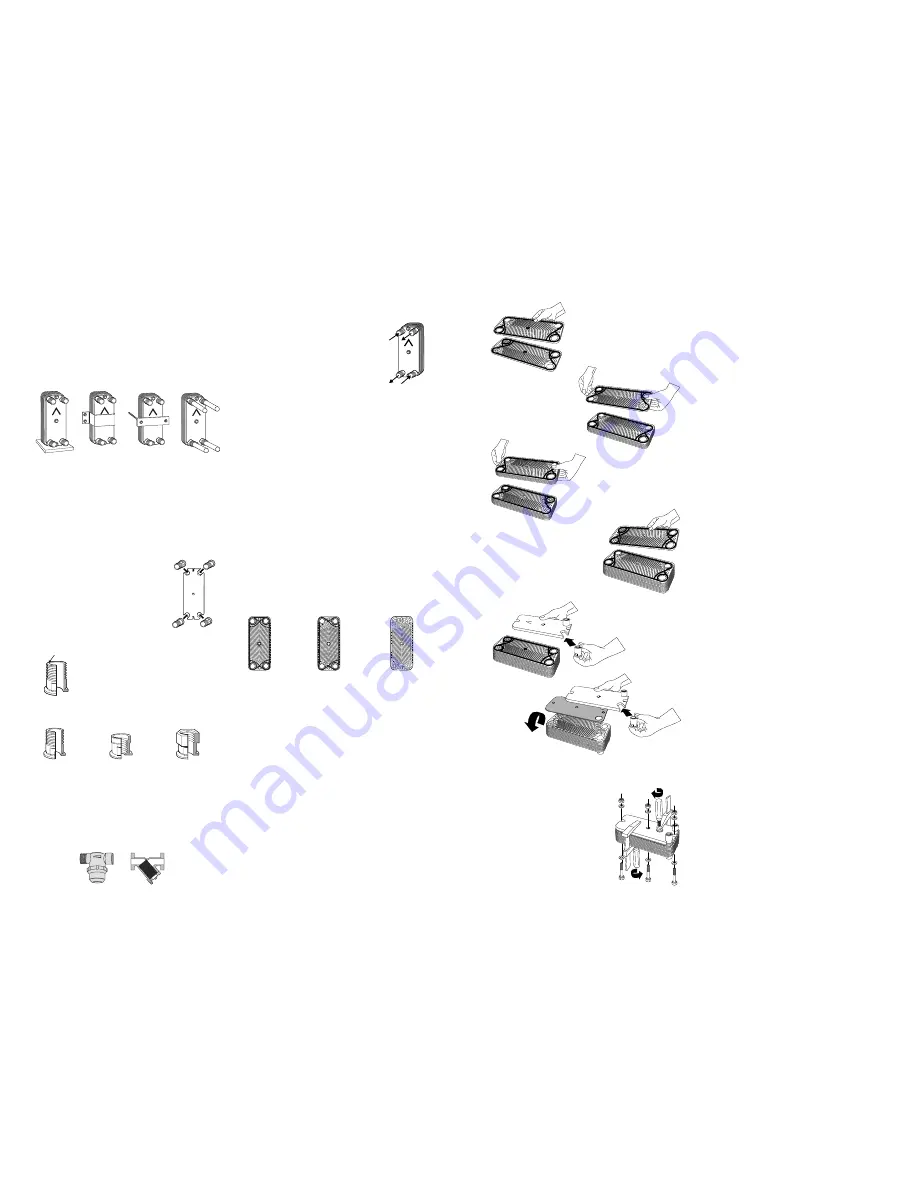

Principle of assembly

There are a few differences such as number of plates, number of packages,

placing of connections etc. when mounting different versions of Minex. The

example below illustrates the assembly of a two-pass Minex.

Figure 1. When assembling the Minex,

start with the last channel plate. The

chevrons of the plate should point

downwards. Alternate the channel

plates so that every second plate has

the arrow pointing up and every

second pointing down all through the

plate package.

Figure 2. A multi-pass unit has a 2-hole

middle plate between the two plate

packages.

Figure 3. When mounting the second

plate package, the chevron on the first

plate should point upwards. Alternate

the channel plates as described in

figure 1. Put the second plate package

on top of the 2-hole plate.

Figure 4. The start plate, which in this

case is a 2-hole plate, should be placed

next. Observe that this plate has a gasket

covering all four corners.

Figure 5. Put the connections into the

designed slots in the front frame and

place the frame on the top of the

package with the arrow pointing up.

Figure 6. Turn the whole package upside-down and place the flat rubber gasket

between the last channel plate and the end cover plate. Please note that the flat

rubber gasket is used only for multi-pass units.

Figure 7. Put the two outer bolts and lock

washers in place and use two screw

clamps to tighten the unit in parallel.

NOTE! If the bolt gets stuck, do not

punch it through the plate package, as

the channel plates can be damaged.

The bolts must be screwed through the

plate package. Finally, put the center

bolt in place and do the final manual

tightening in parallel.

Leakage

If there is leakage when the unit is cold but no signs of leakage during operation,

no action needs be taken. If however there is leakage under normal operating

conditions, the Minex unit should be further tightened. Checked that the unit is

parallel and not out of alignment. Note that the total plate package measurement

is the absolute limit! If the unit leaks when the total plate package measurement is

reached, try to locate the leakage before disassembling in order to be able to pick

out and correct the suspected damaged plates. The gaskets have to be replaced

for all leaking plates. It is important that the frame and channel plates are parallel.

If not, this might cause leakage.

Storage of gaskets

All gaskets are to be stored under appropriate conditions. Gaskets made of NBR

have a shelf life of one year while EPDM gaskets may be stored for up to three

years. This is valid for an assembled Minex as well as separate gaskets. These

time limits are naturally not valid for a unit in service. In practice, the gasket's

lifetime depends on the application and the gasket's exposure to variations in

temperature, pressure and chemical influences, which means that it may affect

the lifetime both positively and negatively. The reason for the restricted shelf life is

that elastomers such as Nitrile and EPDM are oxidized in presence of O , O , UV-

3

2

light etc. This oxidation causes the rubber to harden and ultimately leads to small

cracks in the gaskets.

CLEANING

Thanks to the high degree of turbulence in the Minex, there is a self-cleaning

effect in the channels. However, in some applications the fouling tendency can be

very high, e.g. when using extremely hard water at high temperatures. There are

several different possibilities to clean the unit.

•

CIP cleaning (Cleaning In Place): Clean the exchanger by circulating a

cleaning liquid. Use a tank with weak acid, 5% phosphoric acid or, if the

exchanger is frequently cleaned, 5% oxalic acid. Pump the cleaning liquid

through the exchanger. For optimum cleaning, the cleaning solution flow rate

should be a minimum of 1.5 times the normal flow rate, preferably in a back-

flush mode. After use, do not forget to rinse the heat exchanger thoroughly

with clean water. A solution of 1-2% sodium hydroxide (NaOH) or sodium

bicarbonate (NaHCO ) before the last rinse ensures that all acid is

3

neutralized. Clean at regular intervals.

•

Manual cleaning: Open the unit according to enclosed dismantling directions.

When cleaning a multi-pass unit, make sure where the “2-hole” plate is

located. Since the gaskets are unglued you can easily clean the plates. Use a

fiber brush and water (do not use a steel brush or steel wool). Greasy

deposits, e.g. oil, are removed with a soft brush and paraffin (kerosene).

Organic deposits are removed with a soft brush and alkaline detergent (2%

caustic soda, 50°C (122°F)). Precipitates of calcium components may be

removed with either 10% nitric acid (HNO ) or 2% sodium

3

polymethaphosphat, 50°C (122°F), 2% sodium trimethaphosphate, 50°C

(122°F), 5% EDTA. After cleaning, the heat exchanger should be thoroughly

flushed with clean water. The gaskets, which have been deformed due to the

tightening, have to dry for 24 hours to revert to their original form before

assembly. This procedure will avoid the risk of leakage and should not be

ignored. (Note! You may want to have a spare set of gaskets on hand so you

don't have to wait 24 hours to re-assembly.)

Note that all acids and bases are hazardous and should be handled with great

care.

For further information, please consult SWEP's CIP leaflet or your local SWEP

representative.

WARRANTY

SWEP offers a 12-month warranty from the date of installation, but in no case

longer than 15 months from the date of delivery. The warranty covers

manufacturing and material defects.

DISCLAIMER

SWEP's Minex performance is based on installation, maintenance and operating

conditions done in conformance with this manual. SWEP cannot assume any

liability for Minex units that do not meet these criteria.

For further information, please consult SWEP's technical information or your

local SWEP representative.