FB 465

4

3

2

1

Dok: 101490-GB 0810

Fuel Check

Check that there is fuel in the tank. Top up if necessary.

Engine Oil Level Check

Check the oil level in the crankcase every day. The oil must

reach the edge of the filling hole when the machine is on a

level surface.

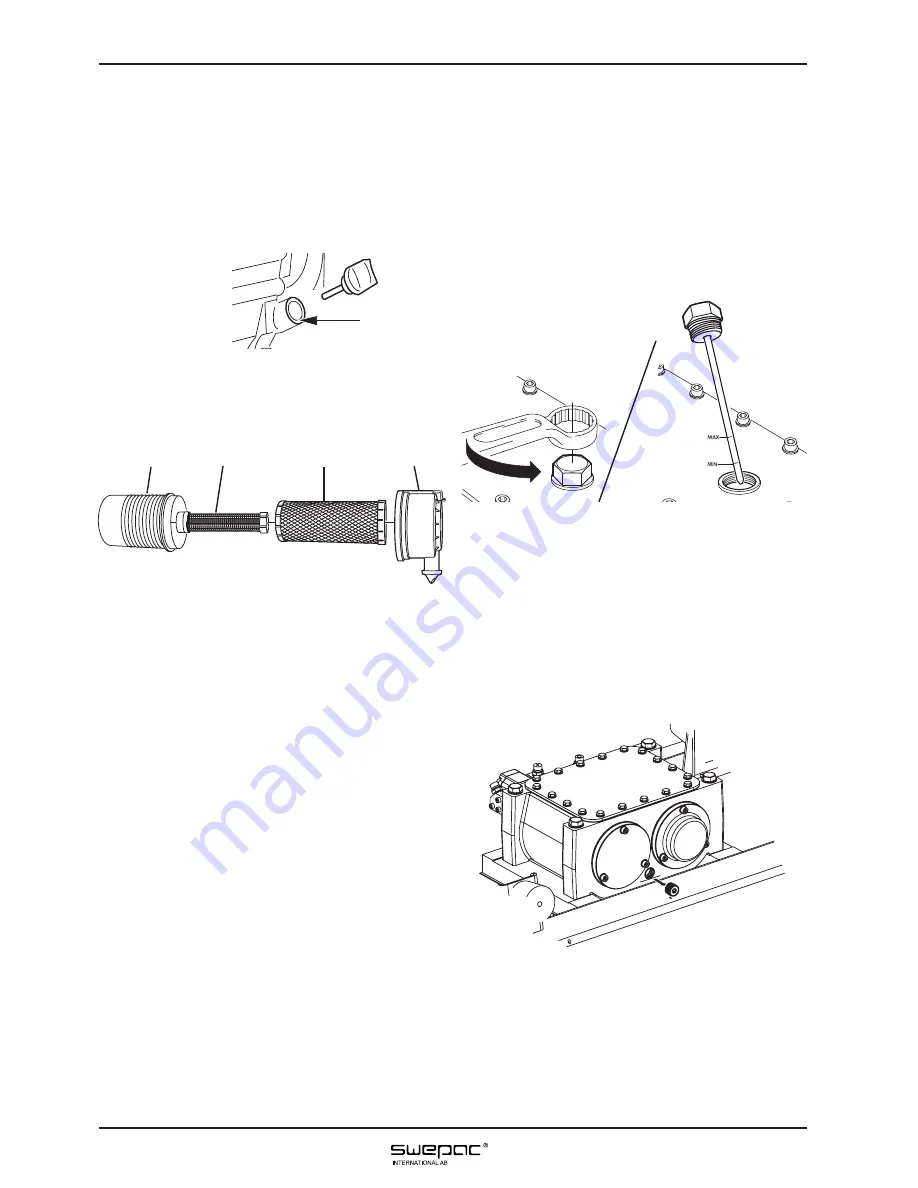

Air Filter Check

The air filter must be checked at least once every working

week.

1.

Filter housing

2.

Safety cartridge

3.

Filter element

4.

Cap

Cleaning

1. Remove the cap and empty out the dust which has

collected. Wipe the cap with a damp cloth.

2.

Carefully remove the filter element and wipe the inside of

the filter housing clean.

3.

Blow the filter clean with dry compressed air, max. 5 bar,

from the inside until no more dust comes out.

Throw the filter element away:

−

if it has been cleaned five times.

−

if it is damaged.

−

after 1000 operating hours or maximum 12 months.

Safety Cartridge

This is normally replaced after around 3000 operating hours

or if the main filter is damaged.

To replace it, remove the filter set as described above and fit

a new safety cartridge.

DAILY CHECKS

Oil/Fuel Leakage

Check every day that the engine is not leaking oil or fuel. If

a leak is discovered, the machine may not be operated until

the fault has been remedied.

Hydraulic Oil Level Check

Check every day that the hydraulic connections do not

leak or wear during operation. Check the oil level with the

dipstick on the top of the tank. The level must be between

“MIN” and “MAX”.

Vibration Element

Check regularly that there is no oil leak. If you suspect a

leak, check the level at the level screw on the vibration ele-

ment. If necessary, add oil up to the lower edge of the level

hole when the vibrator is horizontal. Seal any leaks. Note!

Machines must never be operated if a leak is suspected.

Rubber Dampers

Check the condition of the rubber dampers regularly. Re-

place damaged dampers.