FB 465

1

2

3

Dok: 101490-GB 0810

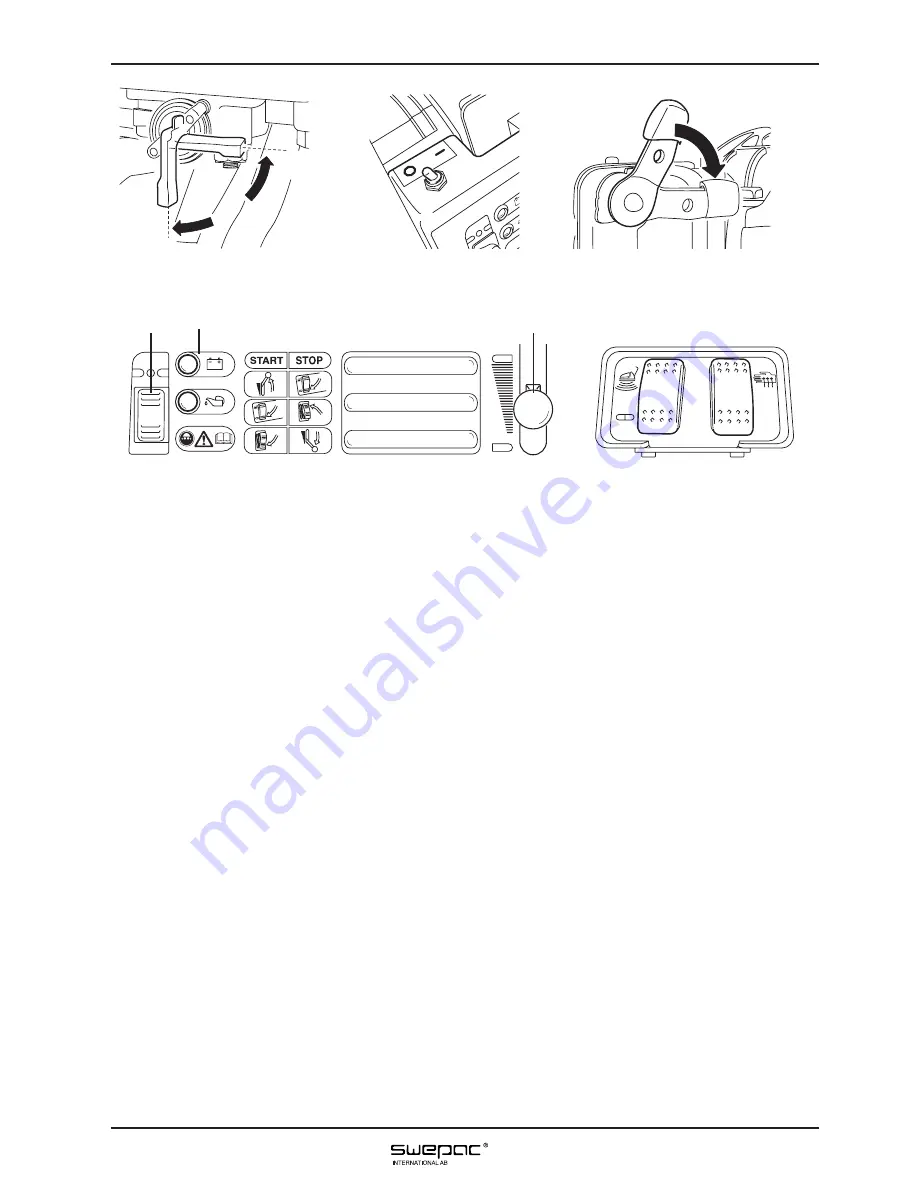

Vibration power switch and

handle heating

Main power switch

Decompression handle

Fuel cock

Instrument panel with;

1. Engine power switch

2. Control lamps for charging and oil pressure

3. Throttle lever

In very cold weather or if the battery capacity is low for

a different reason, starting can be facilitated using the

decompression handle in connection with the valve housing.

Press the lever down and hold it down until the flywheel has

reached its maximum RPM. Run the engine warm for around

5 minutes.

See Daily Checks on page 8.

BEFORE STARTING

STARTING

STOPPING

Open the hood.

Open the fuel cock.

Switch the main power switch, located on the instrument

panel inside the protective cover, to the position “I”.

Close the hood.

Note! The vibration power switch on the handle must

be in the position “vibration off” (red/green marking).

Otherwise the machine cannot be started.

Switch the throttle lever (3) to the full RPM position (green

marking).

Start the engine with the power switch (1). Place the knob

in the central position and check that the charging and oil

pressure lamps (2) light up. Then press the power switch

down (green marking).

Note! Never run the starter motor for longer than 10 seconds

at a time. If the engine does not start, wait 15 seconds before

trying to start it again.

Switch the throttle lever (3) to idle and let the engine run for

a few minutes.

Press the engine power switch (1) upwards (red marking).

Stop the engine by moving the throttle lever to the stop posi-

tion (red marking).

At the End of the Day

Open the hood.

Switch off the main power switch, “O” position.

Close the fuel cock.

Close the hood.

Closed

Open