IMPORTANT!

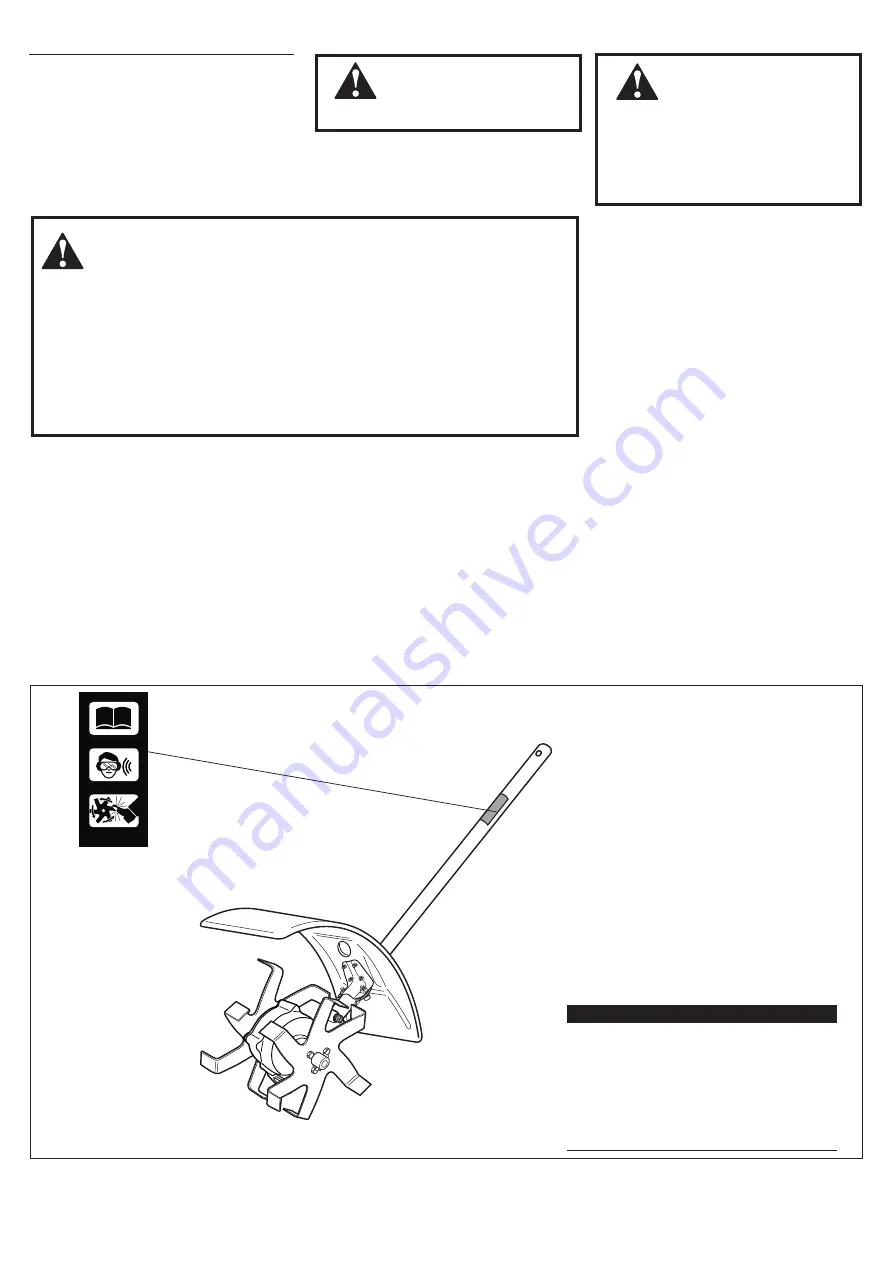

Safety and Operation Information Labels:

Make sure all information labels are

undamaged and readable. Immediately

replace damaged or missing information

labels. New labels are available. Contact

Swisher Inc. at (800) 222-8183, or go to

www.swisherinc.com for asssitance..

Safety Labels

Figure 1

READ THE

OPERATOR’S MANUAL.

W EAR HEAR

ING AND ANS

I Z87.1

APPROVED E

YE PROTE

CTION.

KEEP A

W AY FROM

ROTATING T

INES.

80278

Shindaiwa Inc.

3

This machine operates at very high

speeds and has the potential to do serious

damage if misused, abused or mishandled.

To reduce the risk of injury, you must

maintain control at all times, and observe

all safety precautions during operation.

Never permit a person without training or

instruction to operate this machine!

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

General Safety Instructions

WARNING!

Never make unauthorized

attachment installations.

WARNING!

Never operate power equip-

ment of any kind if you are tired or

if you are under the influence of

alcohol, drugs, medication or any

other substance that could affect

your ability or judgement.

Never

smoke or light fires near the

unit.

Always

stop the engine and allow it

to cool before refueling. Avoid over-

filling and wipe off any fuel that may

have spilled.

Never

place flammable material

close to the engine muffler.

■

■

■

Always

move the unit to a place well

away from a fuel storage area or oth-

er readily flammable materials before

starting the engine. Use caution when

handling fuel. Move the power tool at

least 10 feet (3 meters) from the fuel-

ing point before starting the engine.

Never

run the engine without the

spark arrester screen in place. Do

not operate the machine with the

muffler removed.

■

■

WARNING!

Minimize the Risk of Fire

Be careful when operating on a slope

or on slippery terrain, especially dur-

ing rainy weather.

Never operate this machine around

buried electrical cables!

Do not operate the tiller/cultivator in

standing water.

■

■

■

If the tines jam, switch the engine OFF,

disconnect the spark plug lead, and

inspect the tines, axles and gearcase for

damage.

Never operate the tiller/cultivator

around vines or roots that could tangle

in the tines and cause loss of control.

■

■

Maintain a shallow working angle

and

avoid steep angles of operation. A

steep working angle risks loss of con-

trol of the machine.

Transport the machine with the en-

gine OFF.

■

■

Work Safely: Be Aware of the Working Environment

Summary of Contents for E4-U3006

Page 11: ...NOTES 11...