300 Hour Maintenance

9

Maintenance

WARNING!

Before performing any mainte-

nance, repair, or cleaning work on the

unit, make sure the engine and cutting

attachment are completely stopped.

Disconnect the spark plug wire before

performing service or maintenance.

WARNING!

Non-standard accessories,

cutting attachment, or replacement

parts may not operate properly with

your unit and may cause damage

and lead to personal injury.

Prior to each work day, perform the

following:

Remove all dirt and debris from the

engine, check the cooling fins and

air cleaner for clogging, and clean as

necessary.

Make sure nuts, bolts, and screws

(except carburetor idle speed adjust-

ing screws) are tight.

■

■

Daily Maintenance

Carefully remove any accumulations of

dirt or debris from the muffler and fuel

tank. Check cooling air intake area at

base of crankcase. Remove all debris.

Dirt build-up in these areas can lead to en-

gine overheating, fire, or premature wear.

Clean any debris or dirt from the cut-

ting attachment.

■

■

Check for loose or missing screws or

components. Make sure the cutter at-

tachment is securely fastened.

Check the entire unit for leaking fuel

or grease.

■

■

IMPORTANT!

For detailed maintenance information

about your unit, consult the owner's

manual that was provided with it. If it has

been lost or misplaced, contact Swisher

for a replacement.

NOTE

Using non-standard replacement parts

could invalidate your Swisher warranty.

Gearcase Lubrication

The gearcase should be filled with 60 cc

(2.0 fl.oz.) of Mobil SHC634 Synthetic Gear

Oil. A maximum of 75-80 cc can be used,

but never to exceed 80 cc. Operation with

excessive oil level will result in high operat-

ing temperatures.

Do not overfill!

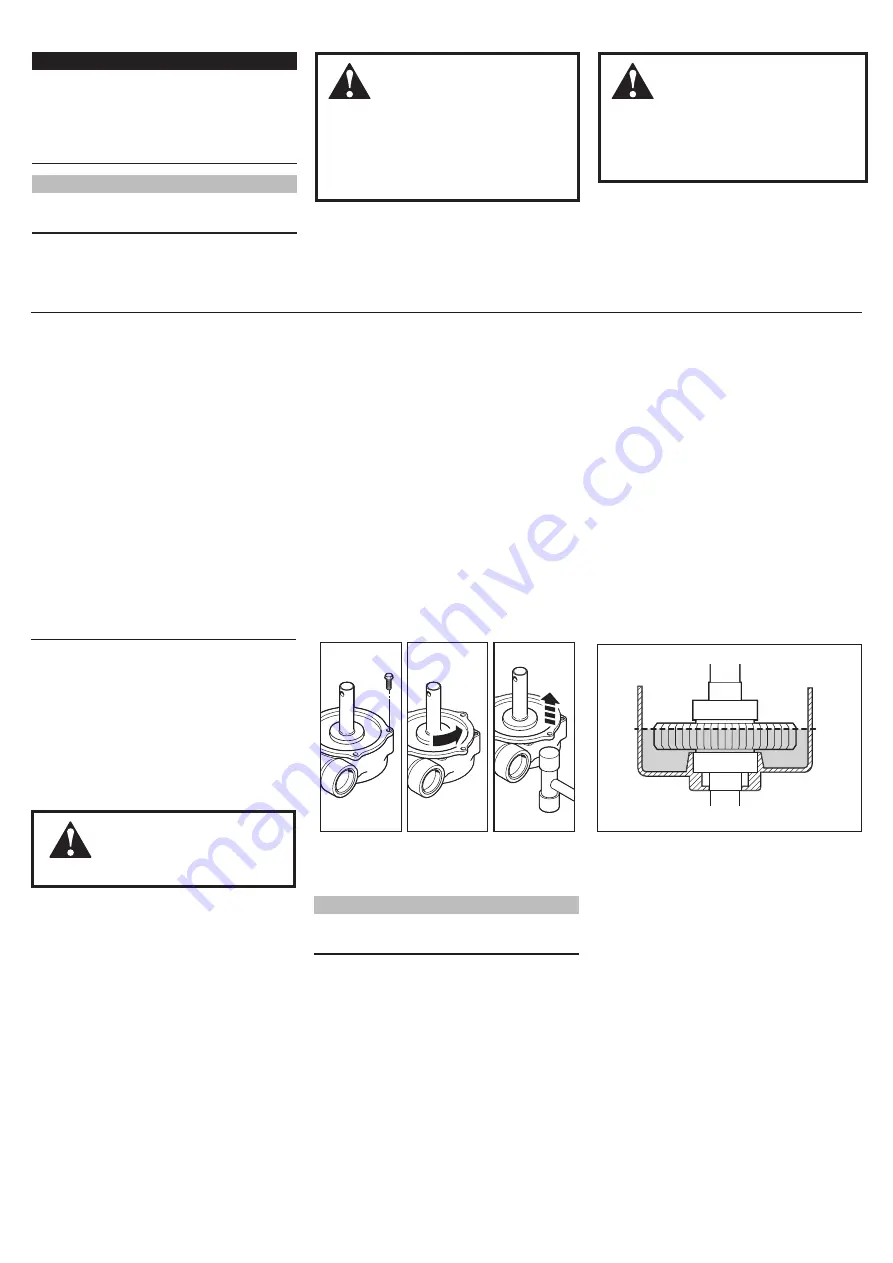

Replacing the gearcase oil

Turn the gearcase to the LH side and

and allow all used gearcase oil to drain

into a small container.

4.

Figure 14

NOTE:

It may be necessary to use a heat gun to

soften the sealer material.

WARNING!

BURN DANGER! The gear-

case will be extremely hot after use!

Disconnect spark plug wire at engine.

Remove the LH Drum and axle assembly

(as viewed from the operating position).

Wipe the sideplate clean and remove four

screws (it is not necessary to remove the

gearcase from the outer tube).

Turn gearcase side plate to break the

seal and lift the plate from the gearcase.

See Figure 13.

1.

2.

3.

Figure 13

Inspect the sideplate for damage and

clean off all remaining liquid gasket mate-

rial with brake cleaner or acetone. Coat

the outer sealing flange of the sideplate

with Loctite Ultragrey Silicon Sealant or

Threebond No. 1104 Liquid Gasket.

Replace the cover and install the four

sideplate screws. Tighten securely.

Reinstall the drum and axle assembly

per the sweeper assembly instructions.

See page 11.

6.

7.

8.

Place the gearcase on the RH side and

supported so the outer tube is paral-

lel to the ground. Refill the gearcase

with 60 cc (2.0 fl.oz) of Mobil SHC634

Synthetic Gear Oil to the bottom of the

chamfer on the output gear. The cor-

rect oil depth is 5/8" (15.5 mm). See

Figure 14. DO NOT OVERFILL! Refer

to Figure 14.

5.

Summary of Contents for E4-U3006

Page 11: ...NOTES 11...