16

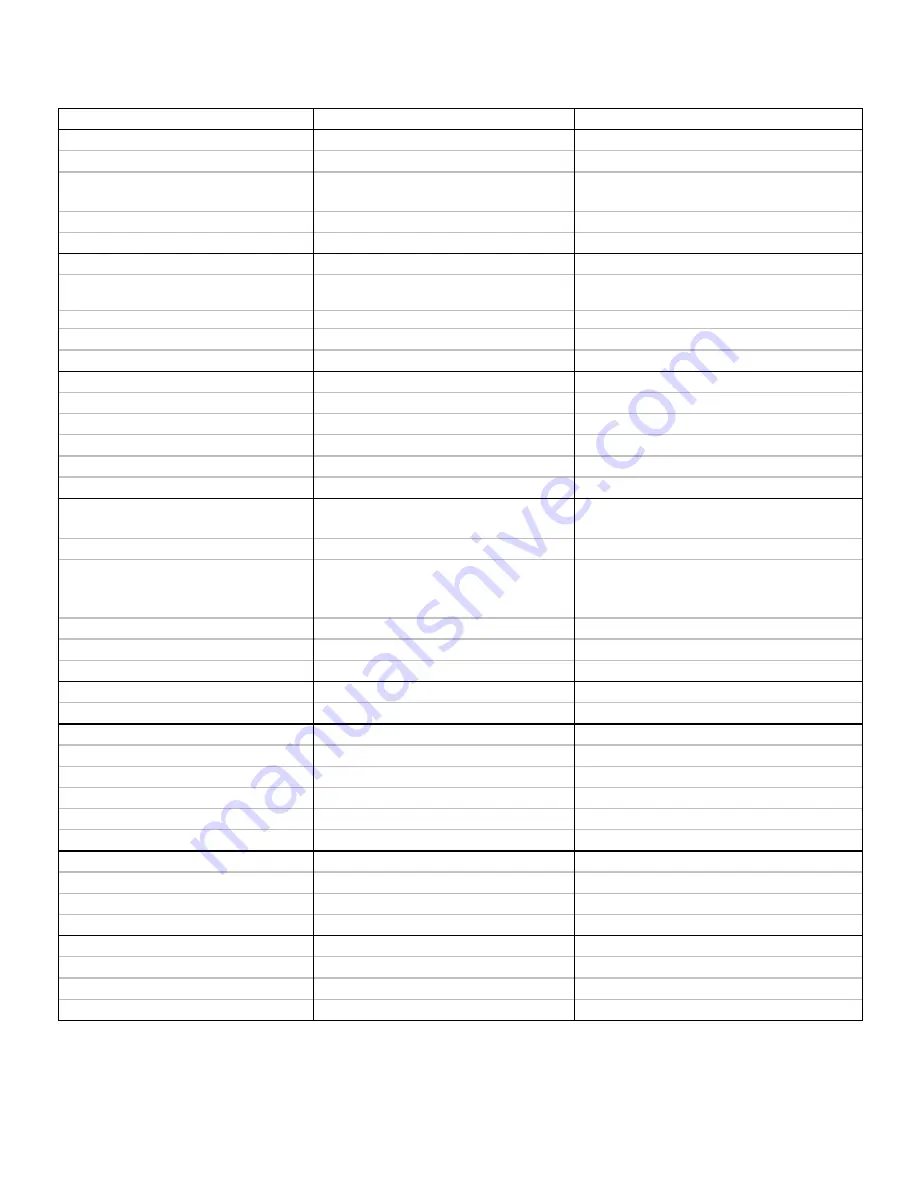

TROUBLESHOOTING

NOTE: For repairs beyond those listed here, contact your nearest authorized service center.

* Flushing the reservoir tank and hoses with kerosene whenever service is performed on the tank, hydraulic pump or

valve is recommended. Contact an authorized service center.

Problem

Cause

Remedy

Engine fails to start.

1. Spark plug wire disconnected.

1. Connect wire to spark plug.

2. Fuel tank not full enough or stale fuel. 2. Fill tank full with clean, fresh gasoline.

3. Throttle control lever not in correct

starting position.

3. Move throttle lever to FAST position.

4. Fuel valve not ON or blocked fuel line. 4. Turn on fuel valve or clean fuel line.

5. Faulty spark plug.

5. Clean, adjust gap, or replace spark plug.

Engine is hard to start or runs erratically. 1. Spark plug wire loose.

1. Connect and tighten spark plug wire.

2. Blocked fuel line or stale fuel.

2. Clean fuel line; fill tank with clean, fresh

gasoline

3. Water or dirt in fuel system.

3. Drain fuel tank. Refill with fresh gasoline.

4. Dirty air cleaner.

4. Clean or replace air cleaner.

5. Carburetor out of adjustment.

5. See authorized service center.

Cylinder rod will not extend or contract. 1. Cold weather clutch not engaged.

1. Engage cold weather clutch.

2. Broken or improperly installed belt.

2. Replace or reinstall belt.

3. Low hydraulic fluid.

3. Fill hydraulic tank to correct fluid level.

4. Hydraulic lines blocked.

4. Flush and clean hydrualic system.*

5. Damaged or broken pump.

5. See authorized service center.

6. Damaged control valve.

6. See authorized service center.

Cylinder rod is slow or erratic while

extending and contracting.

1. Low hydraulic fluid.

1. Fill hydraulic tank to correct fluid level.

2. Contaminated hydraulic fluid.

2. Drain fluid, flush system, and refill.

3. Excessive pump inlet vacuum.

3. Make certain pump hoses are clear and

unblocked. Make certain hose is not

collapsing under suction.

4. Damaged pump.

4. See authorized service center.

5. Damaged control valve.

5. See authorized service center.

6. Internal cylinder damage.

6. See authorized service center.

Cylinder is leaking.

1. Broken seals.

1. See authorized service center.

2. Scored cylinder.

2. See authorized service center.

Engine will not turn over.

1. Weak or dead battery.

1. Recharge or replace battery.

2. Blown fuse.

2. Replace fuse.

3. Corroded battery terminals.

3. Clean battery terminals.

4. Loose or damaged wiring.

4. Check all wiring.

5. Faulty ignition switch.

5. Check/replace ignition switch.

6. Faulty solenoid.

6. Check/replace solenoid.

Engine clicks but will not start.

1. Weak or dead battery.

1. Recharge or replace battery.

2. Corroded battery terminals.

2. Clean battery terminals.

3. Loose or damaged wiring.

3. Check all wiring.

4. Faulty solenoid.

4. Check/replace solenoid.

Battery will not charge.

1. Bad battery.

1. Replace battery.

2. Corroded battery terminals.

2. Clean battery terminals.

3. Faulty solenoid.

3. Check/replace solenoid.

4. Bad alternator.

4. See authorized service center.