TOWING SAFETY

•

Do not allow persons to ride on splitter. Do not carry any cargo or wood on your

splitter. It may fall off and endanger vehicles that are following you.

•

Be sure support leg is in the travel position and coupling secure. This must also

be retracted so not to interfere while towing. Retract support leg by removing

pin, sliding up, and replacing pin.

•

Never exceed 45 MPH while towing your splitter. Be extra cautious when

traveling over rough terrain, especially over railroad tracks.

•

Always be careful while backing your splitter. You could jackknife your log

splitter if not careful.

•

Before using splitter, disconnect it from tow vehicle. A log could easily be

pushed forward into the vehicle.

•

See tire and wheel specifications for PSI while towing.

•

Be aware of the extra length of splitter while turning, parking, crossing

intersections, and in all driving situations.

•

OPERATION INSTRUCTIONS

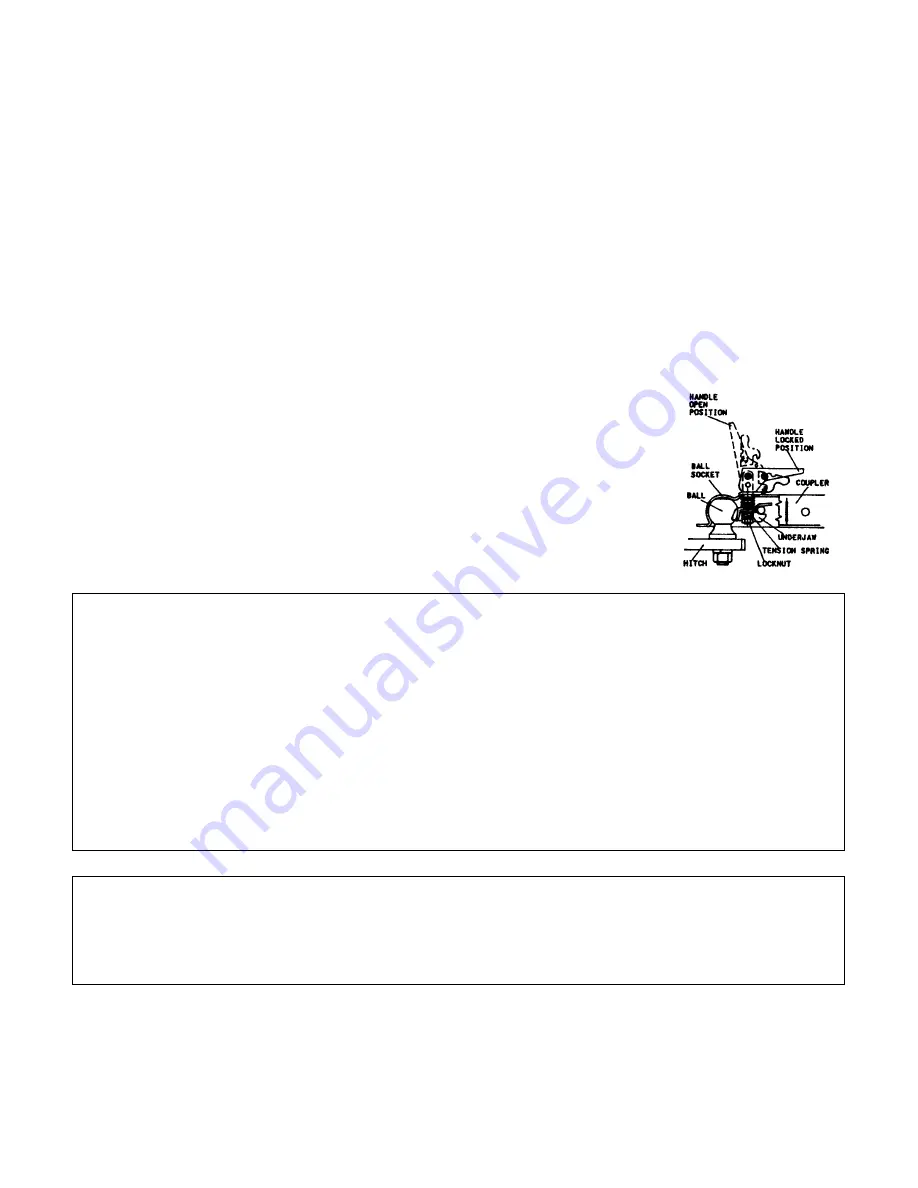

POSI-LOCK COUPLER

ADJUST COUPLER LOCKING PRESSURE ON BALL BEFORE USE. PLACE HANDLE IN LOCKED

POSITION WITH BALL IN COUPLER. TIGHTEN LOCKNUT AGAINST TENSION SPRING SO THAT

COUPLER IS NOT LOOSE ON BALL. CORRECT ADJUSTMENT WILL ALLOW HANDLE TO BE

RELEASED WITH MODERATE PRESSURE APPLIED TO HANDLE.

TO OPEN, PULL UP ON COUPLER HANDLE AND ROTATE FORWARD. PLACE COUPLER ON BALL

WHEN BALL IS COMPLETELY NESTED IN BALL SOCKET, ROTATE COUPLER HANDLE

BACKWARD UNTIL HANDLE IS IN LOCKED POSITION.

AFTER TOWING FOR 50 MILES, CHECK COUPLER FOR TIGHTNESS ON BALL. ALWAYS CHECK

TIGHTNESS BEFORE TOWING. BE SURE COUPLER HANDLE IS IN LOCKED POSITION.

WARNING:

NEVER EXCEED WEIGHT CAPACITY AND ALWAYS USE SAFETY CHAINS. ALWAYS USE

CORRECT BALL SIZE, MAKING SURE BALL IS COMPLETELY INSERTED INTO COUPLER. LOCK

COUPLER HANDLE SECURELY BEFORE TOWING. ALWAYS CHECK FOR DAMAGES AND

REPLACE IF DAMAGED. AVOID SHARP TURNS AND STEEP VERTICAL ANGLES WHEN TOWING.

5