8

GENERAL RECOMMENDATIONS

The warranty on this cutter does not cover items that have been subjected to operator

abuse or negligence. To receive full value from the warranty, operator must maintain

unit as instructed in this manual.

Some adjustments will need to be made periodically to maintain your unit properly.

BEFORE EACH SEASON

A new spark plug and clean air filter assure proper air fuel mixture and help your engine

run better and last longer.

• Replace the spark plug.

• Clean or replace the air filter.

• Check blades and belts for wear.

BEFORE EACH USE

• Check engine oil level. (Do this twice to ensure an accurate reading.)

• Check condition of air filter and clean or replace if necessary.

• Check blade operation.

• Check for loose fasteners.

• Lubricate threads of adjustment rod P/N 4006

figure –3 page 12

DAILY MAINTENANCE

Make sure all nuts and bolts are tight and cotter pins and retainer springs are secure.

Keep blades sharp. Observe all safety precautions.

BLADE CARE AND SERVICE

For best results cutter blades must be kept sharp. The blades can be sharpened with a

few strokes of a file or grinding wheel. Do Not attempt to sharpen while on the cutter.

Important:

Replace blades that have been damaged or deeply nicked.

Important:

Check blade and spindle hardware on a regular basis to make sure

nuts are tight.

CAUTION: DO NOT HANDLE CUTTER BLADES WITH BARE HANDS.

CARELESS OR IMPROPER HANDLING MAY RESULT IN SERIOUS

INJURY.

CUTTER MAINTENANCE

• Reducing the travel speed will help cut dense growth. This allows the blades the

time necessary to make its initial cut, and regain momentum to continue cutting and

discharging debris properly. The engine may stall if you are mowing too fast!

• Do not attempt to cut areas that the tow vehicle cannot maneuver through and/or

slopes that you do not feel comfortable riding.

Summary of Contents for POL12544X

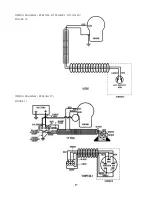

Page 17: ...WIRING DIAGRAM RTB12544 RTB12544EC POL12544X FIGURE 10 WIRING DIAGRAM RTB134412V FIGURE 11 17...

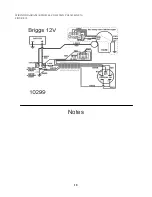

Page 18: ...Notes 18 WIRING DIAGRAM RTB14544 POL14544X POL14544XEX FIGURE 12...

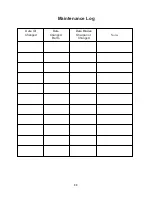

Page 21: ...Maintenance Log Notes Date Oil Changed Date Changed Belts Date Blades Sharpen or Changed 21...

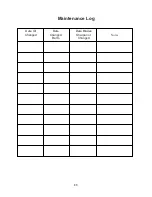

Page 22: ...Maintenance Log Notes Date Oil Changed Date Changed Belts Date Blades Sharpen or Changed 22...

Page 23: ...Maintenance Log Notes Date Oil Changed Date Changed Belts Date Blades Sharpen or Changed 23...