7

CUTTER HEIGHT ADJUSTMENT

• There is approximately 4 inches of height adjustment.

• Rotate height adjust crank handle in a clockwise direction to lower the mower deck.

counter-clockwise direction to lift the mower deck.

• Dense areas of material should be cut twice.

• Push handle down to lock height position.

TOW HITCH OFFSET

• When offsetting the cutter do so to the side opposite the discharge of the tow

vehicle.

• Swisher recommends if the tow vehicle is equipped with a mid-mount mower to

overlap the cut approximately 6”. This may vary depending on mowing terrain,

obstacles, and/or tow vehicle. Always keep safety the first priority.

• Always keep the tow vehicle cutter raised higher than the Trailcutter

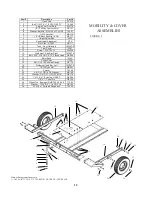

• To change the offsetting position both ball-lock pins should be removed (

Figure

2

). The hitches

will swivel around remaining bolts. Set hitches to desired positions and return ball-

lock pins, making

sure they go through the hitch tubing and the semi-circled hole patterned plates.

STARTING TO CUT

• Adjust the cutting height.

• Double check vehicle to cutter attachment.

• Start mower engine and set throttle to “FAST” for best cutting performance.

• Slowly engage T-handle lever.

See figure-8 page 16

• Carefully mount tow vehicle and start mowing at a slow travel speed.

STOPPING THE CUTTING SESSION

• Bring tow vehicle to a complete stop, set the parking brake and disengage blades.

• Turn key switch to the “OFF” position.

• Always remember to remove keys to avoid irresponsible usage.

SUGGESTED CUTTING PRACTICES

• Operate cutter engine at full throttle to assure the best cutting performance and

maximum material discharge.

• Allow wet grass to dry. Wet grass will clump and collect under the mowing deck.

• Cutter should be started with tow vehicle in low gear and increased only as safe

mowing conditions permit. Cutting speed should not exceed 5 MPH.

• Cutting conditions and the types of grass will vary from place to place. You may

find when cutting dense areas that the pressure of the wheel tracks may cause the

grass to be pushed down and not effectively mowed. If this happens you may want

to mow the area twice. Once with the cutter raised and the second cutting at the

desired height. The second cutting should be at a right angle from the previous for

best results.