16

5.

Check the tension of the drive belt by compressing it in the middle. The drive belt has the correct tension

when it can be compressed by about 5 mm. If the belt is too slack, it may creep on the wheels and may be

destroyed. If the belt is too tight it will overload the motor and put excessive stress on all bearings. After that,

reattach the drive cover.

Lubricating sleeve bearings

Lubricate the sleeve bearing with 30 WT oil every 10 hours of operation. No other lubrication is necessary for this

machine.

Disconnect the machine from the power source!

1.

Remove the sanding belt.

2.

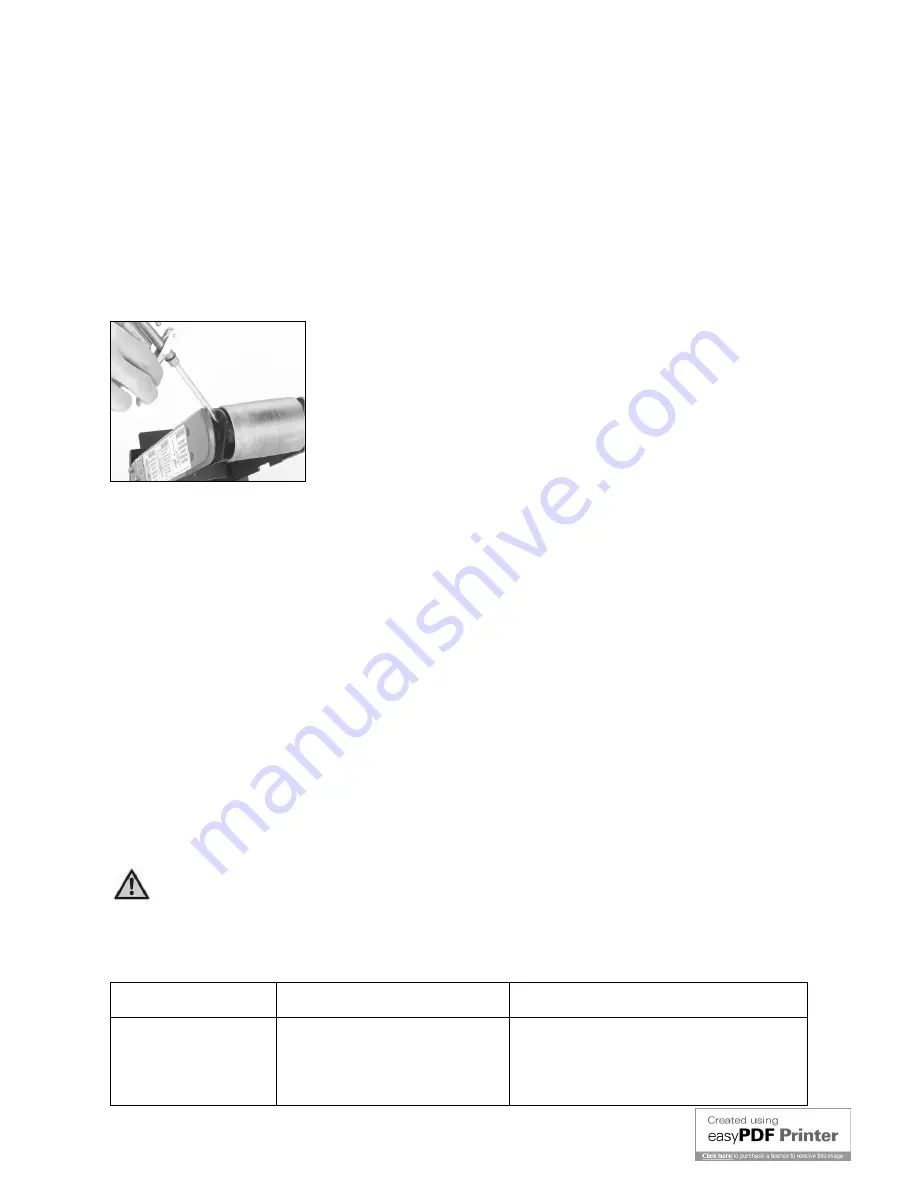

Apply two or three drops of oil in the hole at the end of the idler pulley.

Note

!

DO NOT apply extra oil. Too much oil can cause the belt to slip.

Following maintenance schedule ensures that your machine is safe and performs accurately.

Check the following items before you use the disc sander:

Loose mounting bolts.

Worn loose, or damaged sanding disc.

Worn or damaged wires.

-

Any other condition that could hamper the safe operation of this machine.

Perform the following tasks at the scheduled time intervals:

After Each Use

Wipe off the sawdust build-up from the table surface.

Regularly clean the dust extraction openings with a stiff brush.

Use a maybe slightly moistened cloth to clean the machine. Carefully dry the machine before the next

use. Do not use solvents, abrasives or aggressive chemicals.

Do not allow liquids of any kind to enter the machine and do not immerse any part of the machine in

liquids.

Weekly

Wipe a lubricant onto the disc table.

TROUBLE SHOOTING

DANGER!

Many accidents happen particularly in connection with problems and malfunctions. Therefore

please note:

Always unplug before servicing.

Check that all safety devices are operational again after each fault service.

Trouble

Possible cause

Suggested corrective action

Grains easily rub off the

belt or disc.

1. Sanding belt/disc has been

stored in an incorrect environment.

2. Sanding belt/disc has been

smashed or folded.

1. Store sanding belt/disc away from

extremely hot or dry temperatures.

2. Store sanding belt/disc flat not bent or

folded.